Method for preparing biological-based plastics by using wood fibers as raw material

A technology of bio-based plastics and wood fiber, which is applied in the field of preparation of bio-based plastics, can solve the problems that no modified products can be injection molded, and the failure to successfully prepare lignocellulosic bio-based plastics, etc., achieves broad industrial application prospects, Good mechanical properties and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

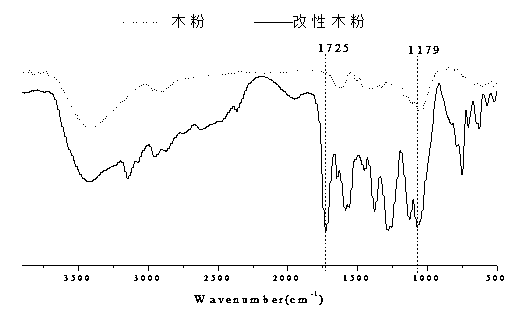

[0028] A method for preparing bio-based plastics using wood fiber as a raw material, the specific steps are:

[0029] (1) Take hibiscus branches as raw materials, peel them, dry them in the air, crush them mechanically, and dry them.

[0030] (2) The raw material is pretreated by ball milling with a planetary ball mill, and the ball milling time is 15 hours. The ball mill jar is made of zirconia, with a capacity of 250mL. The ratio of raw materials to balls is 1:10, and the ratio of large, medium and small balls is 1:6:9. The ball milling speed is 580 r / min. min alternates once.

[0031] (3) Dissolve 18g of phthalic anhydride in 75g of N-methylimidazole.

[0032] (4) Dissolve 1.25g of p-dimethylaminopyridine in the solution obtained in step (3).

[0033] (5) Mix 9 g of ball-milled wood flour with the solution obtained in step (4), and stir mechanically at room temperature for 2 hours.

[0034] (6) After the reaction is complete, add acetone for full separation, and wash wi...

Embodiment 2

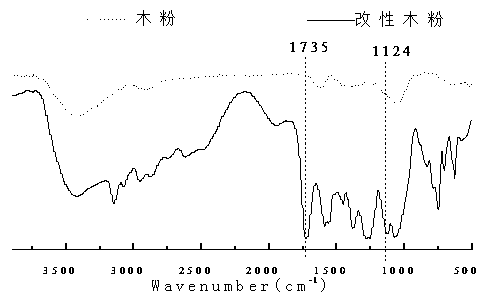

[0038] A method for preparing bio-based plastics using wood fiber as a raw material, the specific steps are:

[0039] (1) Take hibiscus branches as raw materials, peel them, dry them in the air, crush them mechanically, and dry them.

[0040] (2) The raw material is pretreated by ball milling with a planetary ball mill, and the ball milling time is 15 hours. The ball mill jar is made of zirconia, with a capacity of 250mL, the ratio of raw materials to grinding balls is 1:10, and the ratio of large, medium and small balls is 1:6:9. The rotational speed of the ball mill is 580 r / min, and there is no time interval between forward and reverse rotation; alternately every 90 min.

[0041] (3) Dissolve 18g of phthalic anhydride in 75g of N-methylimidazole.

[0042] (4) Mix 9 g of ball-milled wood powder with the solvent obtained in step (3), and stir mechanically at room temperature for 2 hours.

[0043] (5) After the reaction is completed, add acetone for full separation, and was...

Embodiment 3

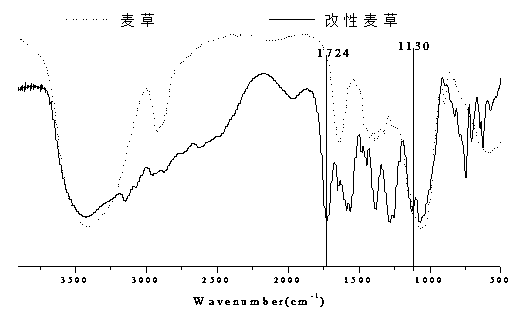

[0047] A method for preparing bio-based plastics using wood fiber as a raw material, the specific steps are:

[0048] (1) Poplar wood is used as raw material, peeled, air-dried, mechanically crushed, and dried.

[0049](2) The raw material is pretreated by ball milling with a planetary ball mill, and the ball milling time is 15 hours. The ball mill jar is made of zirconia, with a capacity of 250mL, the ratio of raw materials to grinding balls is 1:10, and the ratio of large, medium and small balls is 1:6:9. The ball milling speed is 580 r / min, and there is no time interval between forward and reverse rotation, which is alternated every 90 min.

[0050] (3) Dissolve 18g of phthalic anhydride in 75g of N-methylimidazole.

[0051] (4) Dissolve 1.25 g of p-dimethylaminopyridine in the solution obtained in step (3).

[0052] (5) Mix 9 g of ball-milled wood flour with the solution obtained in step (4), and stir mechanically at room temperature for 2 hours.

[0053] (6) After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com