Dye-sensitized solar cell (DSSC) photo-anode and manufacturing method and application thereof

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve problems such as easy cracking of porous membranes, influence on electron transport, and inability to combine particles, so as to improve photoelectric conversion efficiency, increase reuse efficiency, and increase secondary absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

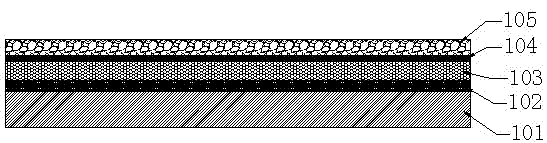

[0052] A photoanode for a dye-sensitized solar cell, such as figure 1 , is a five-layer laminated structure, which is a conductive substrate 101, a first dense layer 102, a transmission layer 103, a second dense layer 104, and a scattering layer 105 in sequence.

[0053] The conductive substrate 101 is FTO glass; the first dense layer 102 and the second dense layer 104 are a layer of dense TiO 2 membrane;

[0054] The transmission layer 103 is nano-TiO 2 Porous membrane;

[0055] The scattering layer 105 is crystalline TiO 2 diffuser film.

[0056] The film thickness of the transmission layer is 12 μm; the film thickness of the scattering layer is 10 μm.

[0057] Its preparation method is:

[0058] 1) Clean the conductive substrate FTO glass;

[0059] Clean with glass cleaner first, then ultrasonically clean with acetone and ethanol, and finally rinse the conductive substrate with deionized water and dry at 60°C;

[0060] 2) Formation of the first dense layer

...

Embodiment 2

[0078] A photoanode for a dye-sensitized solar cell, such as figure 1 , is a five-layer laminated structure, which is a conductive substrate 101, a first dense layer 102, a transmission layer 103, a second dense layer 104, and a scattering layer 105 in sequence.

[0079] The conductive substrate 101 is FTO glass; the first dense layer 102 and the second dense layer 104 are a layer of dense TiO 2 membrane;

[0080] The transmission layer 103 is nano-TiO 2 Porous membrane;

[0081] The scattering layer 105 is crystalline TiO 2 diffuser film.

[0082] The film thickness of the transmission layer is 10 μm; the film thickness of the scattering layer is 12 μm.

[0083] Its preparation method is:

[0084] 1) Clean the conductive substrate FTO glass;

[0085] Clean with glass cleaner first, then ultrasonically clean with acetone and ethanol, and finally rinse the conductive substrate with deionized water and dry at 60°C;

[0086] 2) Formation of the first dense layer

...

Embodiment 3

[0099] A photoanode for a dye-sensitized solar cell, such as figure 1 , is a five-layer laminated structure, which is a conductive substrate 101, a first dense layer 102, a transmission layer 103, a second dense layer 104, and a scattering layer 105 in sequence.

[0100] The conductive substrate 101 is FTO glass; the first dense layer 102 and the second dense layer 104 are a layer of dense TiO 2 membrane;

[0101] The transmission layer 103 is nano-TiO 2 Porous membrane;

[0102] The scattering layer 105 is crystalline TiO 2 diffuser film.

[0103] The film thickness of the transmission layer is 10 μm; the film thickness of the scattering layer is 8 μm.

[0104] Its preparation method is:

[0105] 1) Clean the conductive substrate FTO glass;

[0106] Clean with glass cleaner first, then ultrasonically clean with acetone and ethanol, and finally rinse the conductive substrate with deionized water and dry at 60°C;

[0107] 2) Formation of the first dense layer

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com