PBN-type InGaAs infrared detector

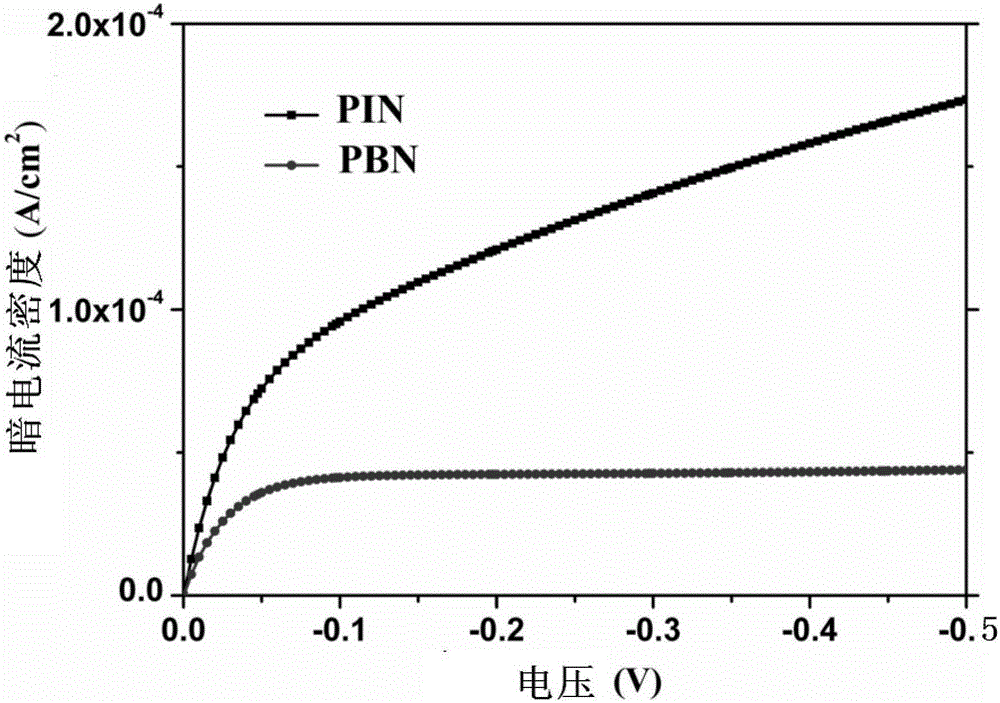

An infrared detector, n-type technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., to achieve the effects of suppressing dark current generation, wide response range, and improving quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A PBN-type InGaAs infrared detector structure with a cutoff wavelength of 2.6 μm is: sequentially grown on an n-type InP substrate with a thickness of 1 μm and a Si doping concentration of 2×10 18 cm -3 n-type InAs 0.60 P 0.40 Buffer layer, continue to grow with a thickness of 3 μm and a Si doping concentration of 8×10 16 cm -3 In 0.82 Ga 0.18 As absorption layer, regrowth thickness is 200nm, Si doping concentration is 2×10 16 cm -3 In 0.82 al 0.18 As barrier layer, the final growth thickness is 100nm, Be doping concentration is 2×10 17 cm -3 p-type In 0.82 Ga 0.18 The As window layer forms a PBN detector structure.

[0029] The manufacturing method of the above-mentioned PBN-type InGaAs infrared detector can firstly grow Si-doped InAs on the n-type InP substrate by using the MOCVD system on the InP substrate using a two-step method. 0.60 P 0.40 The buffer layer, that is, the first step is to grow a layer of InAs with a thickness of 100nm at a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com