Lithium battery cathode material, cathode, lithium battery, preparation method and communication equipment thereof

A negative electrode material, lithium battery technology, applied in the direction of battery electrodes, electrolyte storage battery manufacturing, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process, complicated preparation process, difficult commercialization, etc., to avoid preparation The effect of complex process, reduced production cost, and mature process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

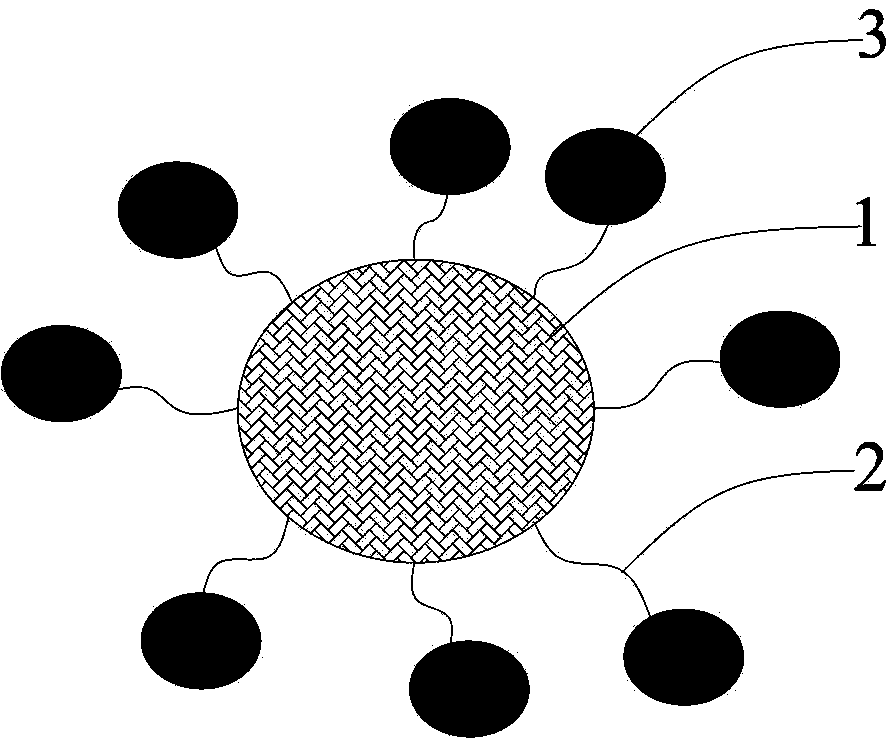

[0072] In one embodiment, the nanomaterial 1 is a nano-element particle and / or a nano-alloy particle, the organic group 2 is uniformly bonded to the surface of the nanomaterial 1, and the metal particle 3 is adsorbed on the organic group 2, so that the metal particle 3 is evenly distributed around the nanomaterial 1, so that the microstructure of the negative electrode material of the lithium battery is spherical or approximately spherical, and its structure is as follows figure 1 shown.

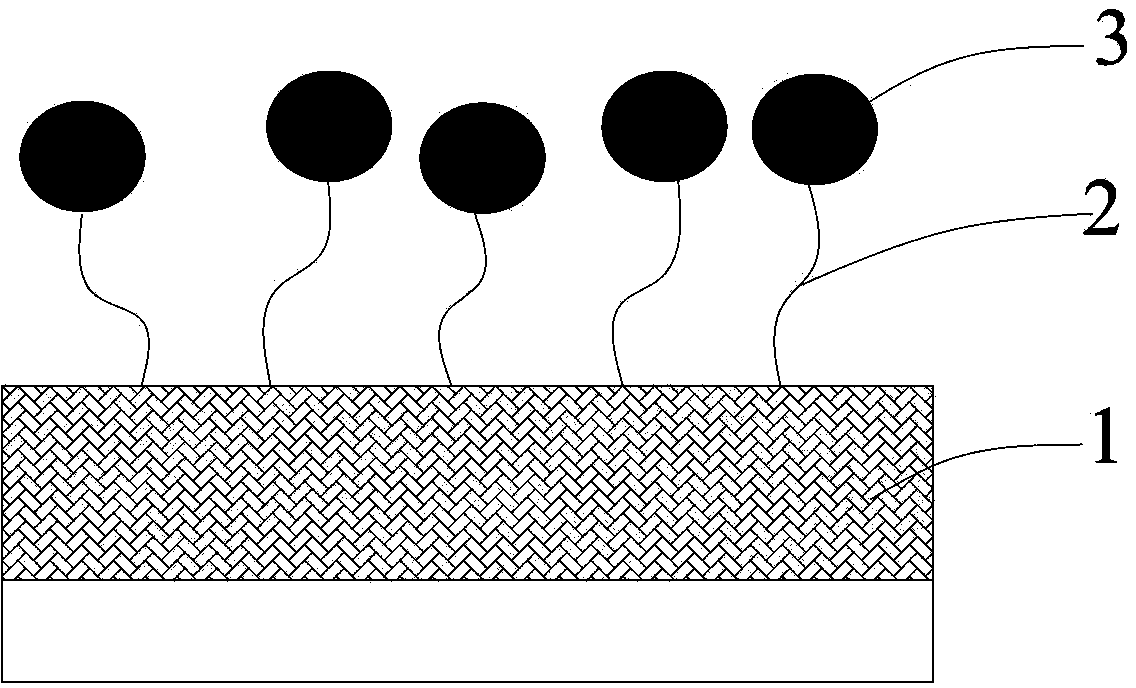

[0073] In another embodiment, the nanomaterial 1 is at least one of nanowires, nanotubes, and nanofibers, the organic group 2 is uniformly bonded to the surface of the nanomaterial 1, and the metal particles 3 are adsorbed on the organic group 2, In this way, the metal particles 3 are evenly distributed around the nanomaterial 1, so that the microstructure of the negative electrode material of the lithium battery is similar to that of nanowires, nanotubes or / and nanofibers, the figure is omi...

Embodiment 1

[0125] A lithium battery negative electrode material and preparation method thereof, lithium ion battery:

[0126] The lithium battery negative electrode material has a microstructure such as figure 1 As shown, the lithium battery negative electrode material includes a nanomaterial 1 that can be alloyed with lithium, an organic group 2 bonded to the surface of the nanomaterial 1 and a metal particle 3 adsorbed on the organic group 2 . Wherein, the nanomaterial 1 is in electrical contact with the metal particle 3 through an organic group 2, the nanomaterial 1 is a 100nm silicon particle; the organic group 2 is p-aminophenylacetic acid; the metal particle 3 is an Ag particle.

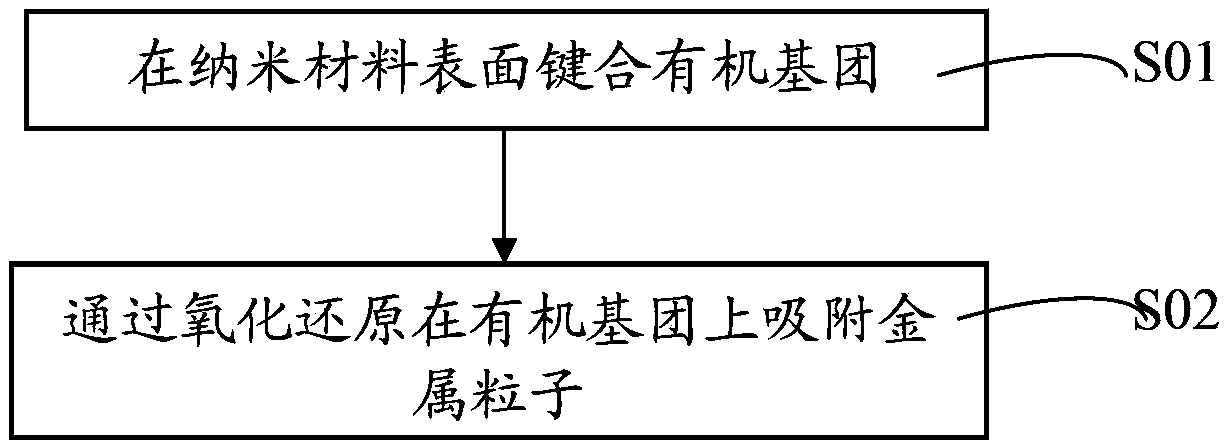

[0127] The lithium battery negative electrode material preparation method is as follows:

[0128] Pretreatment: Add 0.1g of silicon powder with an average diameter of about 100nm to 20mL of organic solvent, and then add 0.3mL of NH 4 Solution F (4% by mass) was stirred for 5 minutes to remove the oxide ...

Embodiment 2

[0136] A lithium battery negative electrode material and preparation method thereof, lithium ion battery:

[0137] The lithium battery negative electrode material, its microstructure refers to the lithium battery negative electrode material prepared in Example 1.

[0138] The lithium battery negative electrode material preparation method is as follows:

[0139] Pretreatment: add 0.1g of silicon powder with an average diameter of 100nm to 5mL of organic solvent, then add 0.3mL of HF solution (4% by mass) and react for 30min under stirring conditions to remove the oxide layer on the surface of silicon particles;

[0140] Bonding organic groups on the surface of the nano-silicon material: adding 0.025 g of p-aminobenzenesulfonic acid and 0.5 mL of organic esters to the solution in the pretreatment step, and reacting for 20 h under stirring conditions. Suction filter the obtained product, and wash with absolute ethanol until the filtrate is colorless, and then dry the obtained po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com