A kind of bone implant filling material and preparation method thereof

A filling material and bone grafting technology, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, and pharmaceutical sciences, etc., can solve the problem that the protein is not easily absorbed and degraded by immobilized calcium sulfate, and achieves no or low immunogenicity, easy to use. Effects of shaping, biodegradability and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

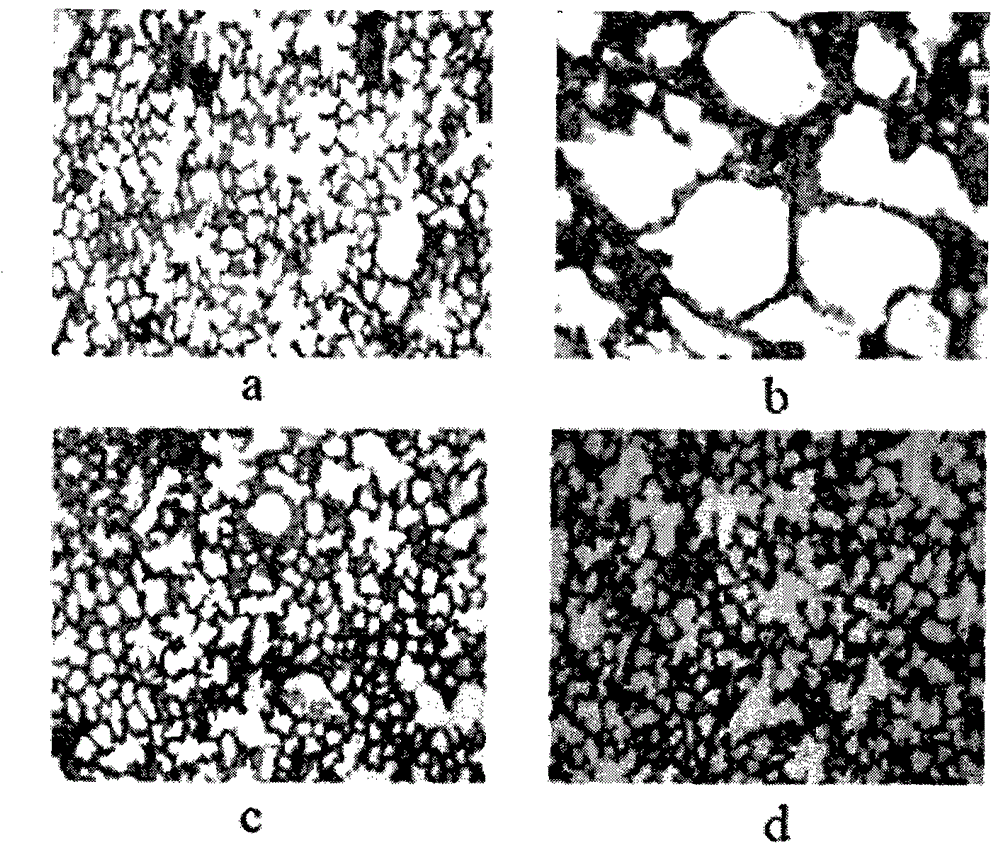

Image

Examples

Embodiment 1

[0029] (1) Mix 10g of biphasic calcium phosphate, 10g of calcium sulfate and 1g of iron oxide and grind them to a particle size of 0.1-1 mm, heat up to 800°C at a rate of 10°C / min and calcinate for 3 hours, take out the calcined bone and place it in the 1M (NH 4 ) 2 HPO 4 Soak in the solution for 24 hours, dry for 2 days, heat up again at a rate of 5°C / min to 1100°C for 1 to 2 hours, slowly cool down, rinse twice with deionized water, and dry at 50°C to obtain a skeleton structure;

[0030] (2) 15g, 0.5mm thick layer of collagen surface spraying 2g bone morphogenetic protein, at this bone morphogenetic protein surface spraying 15 and another layer of 0.5mm thick collagen protein, obtain composite protein layer, described compound The protein layer is dried at 30°C and ultrafinely pulverized to obtain protein particles with a particle size of 50-100nm;

[0031] (3) Add 10 g of the skeleton structure and 15 g of protein particles into 60 ml of absolute ethanol, and place it u...

Embodiment 2

[0034] (1) Mix 10g of biphasic calcium phosphate, 20g of calcium sulfate and 2g of iron oxide and grind them to a particle size of 0.1-1 mm, heat up to 800°C at a rate of 10°C / min and calcinate for 3 hours, take out the calcined bone and place it in 1M (NH 4 ) 2 HPO 4 Soak in the solution for 24 hours, dry for 2 days, heat up again at a rate of 5°C / min to 1100°C for 1 to 2 hours, slowly cool down, rinse twice with deionized water, and dry at 50°C to obtain a skeleton structure;

[0035] (2) 15g, 0.4mm thick layer of collagen surface spraying 5g bone morphogenetic protein, at this bone morphogenetic protein surface spraying another layer of 15g, 0.4mm thick collagen, obtain composite protein layer; The composite protein layer is dried at 30°C and ultrafinely pulverized to obtain protein particles with a particle size of 50-100nm;

[0036] (3) Add 40g of skeleton structure and 25g of protein particles into 80ml of absolute ethanol, and place it under the conditions of 1-5°C a...

Embodiment 3

[0039] (1) Mix 10g of biphasic calcium phosphate, 20g of calcium sulfate and 1g of iron oxide and crush them to a particle size of 0.1-1 mm, heat up to 800°C at a rate of 10°C / min and calcinate for 3 hours, take out the calcined bone and place it in the 1M (NH 4 ) 2 HPO4 Soak in the solution for 24 hours, dry for 2 days, heat up again at a rate of 5°C / min to 1100°C for 1 to 2 hours, slowly cool down, rinse twice with deionized water, and dry at 50°C to obtain a skeleton structure;

[0040] (2) 10g, 4mm thick layer of collagen surface spraying 5g sustained-release agent, spray another layer of 20g, 4mm thick collagen on this sustained-release agent surface, obtain composite protein layer, described slow-release agent is 2g A mixture of bone morphogenetic protein, 2 g of fibronectin, and 1 g of hyaluronic acid; drying the composite protein layer at a temperature of 30° C., and ultrafinely pulverizing to obtain protein particles with a particle size of 50-100 nm;

[0041] (3) A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com