Classified waste oil recycling device and method

A first-class, oil valve technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of strict maintenance and maintenance requirements, easy blockage of membrane pores, and high requirements for filter membrane materials, and achieve effective Reuse, no secondary pollution, obvious environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The technical route and the realization of the goals of the present invention will be described in detail below in conjunction with the accompanying drawings.

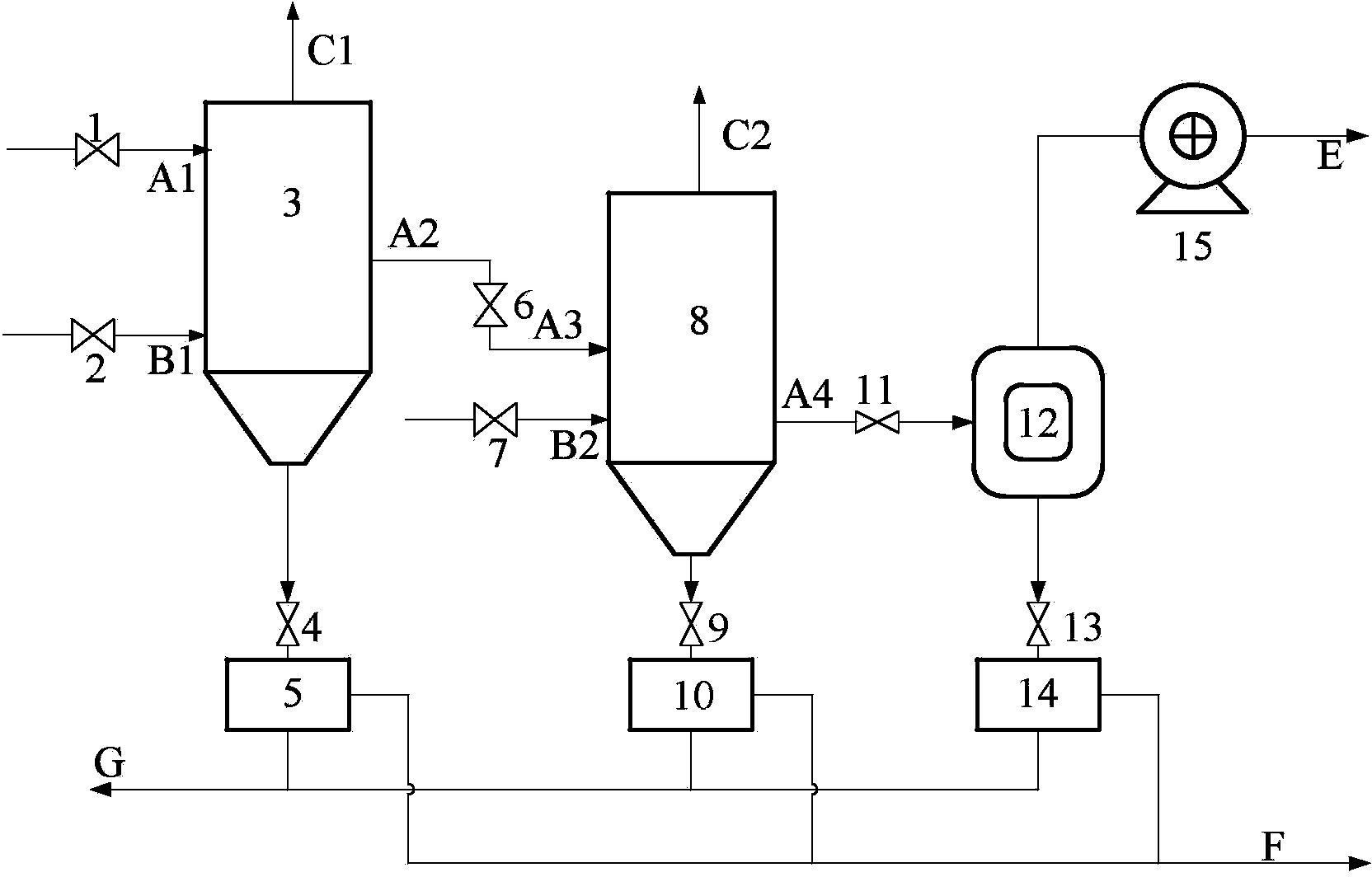

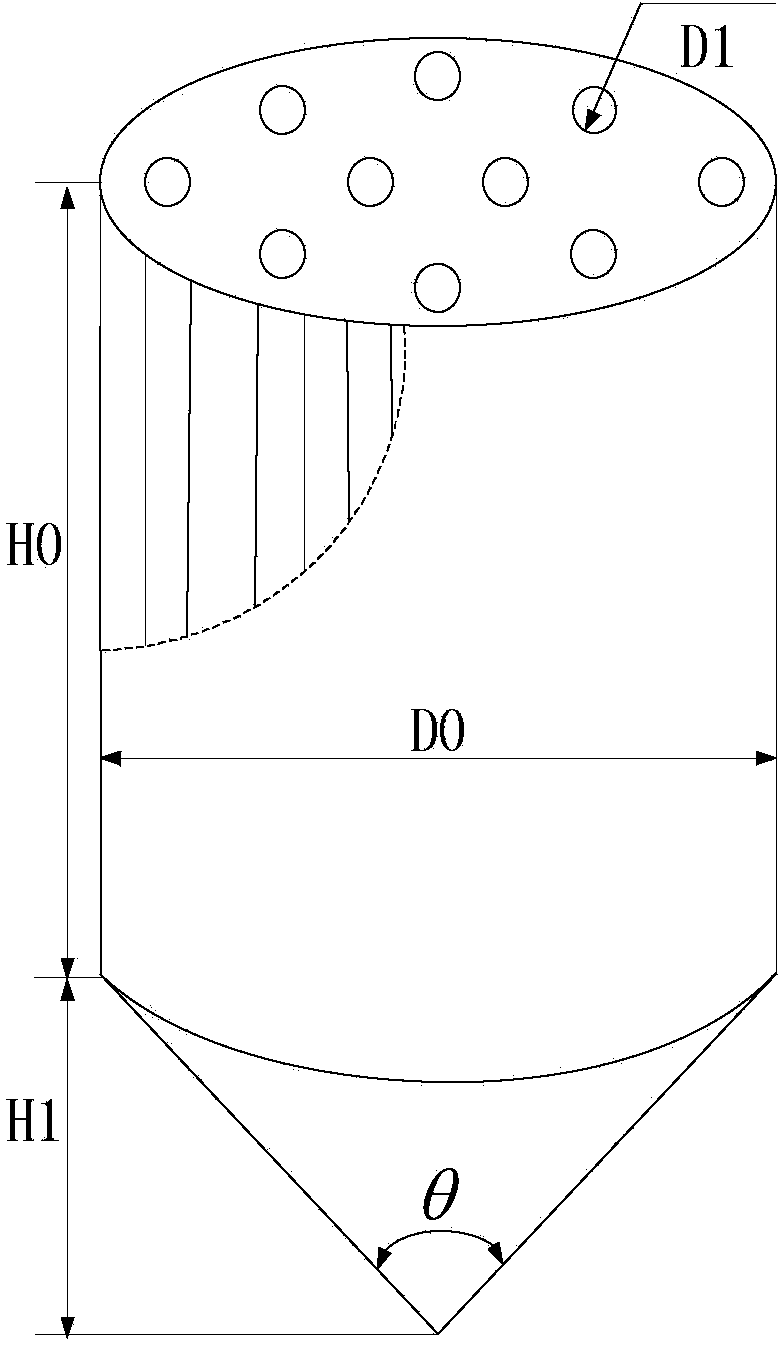

[0024] The device of the present invention comprises a waste oil valve 1, a primary flue gas valve 2, a primary settling tank 3, a primary water slag valve 4, a primary water slag separation box 5, a primary oil valve 6, a secondary smoke valve 7, Secondary settling tank 8, secondary slag valve 9, secondary slag separation box 10, secondary oil valve 11, centrifuge 12, tertiary slag valve 13, tertiary slag separation box 14 and pump 15. Among them, the waste oil valve 1 is connected with the waste oil inlet A1 of the primary settling tank 3, the primary flue gas valve 2 is connected with the primary flue gas inlet B1 of the primary settling tank 3, and the high-temperature flue gas entering the primary settling tank 3 is The first-level flue gas is discharged from outlet C1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com