Completely biodegradable polylactic acid fiber non-woven fabric filtering material

A technology of polylactic acid fiber and polylactic acid short fiber, which is applied in the field of polylactic acid fiber non-woven filter materials, can solve the problems that cannot be completely solved, such as filters, high dependence on oil, and difficult waste disposal, so as to increase dust holding capacity, Good bulkiness and elastic recovery rate, easy adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

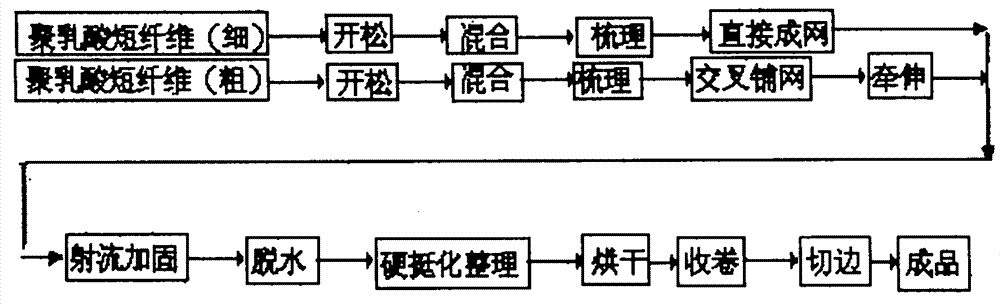

Method used

Image

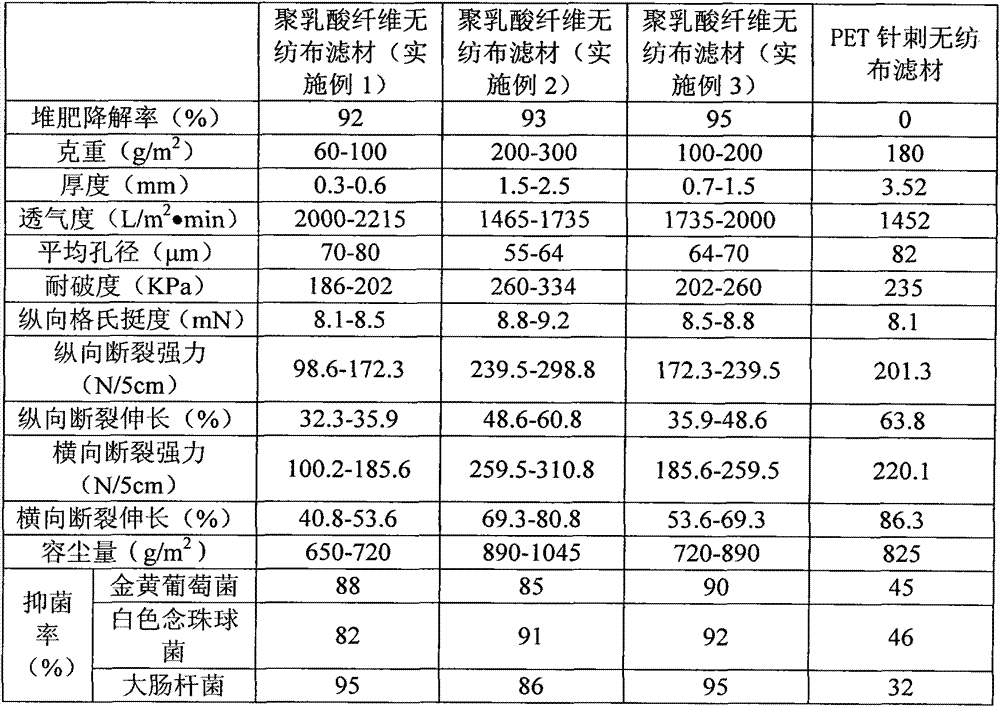

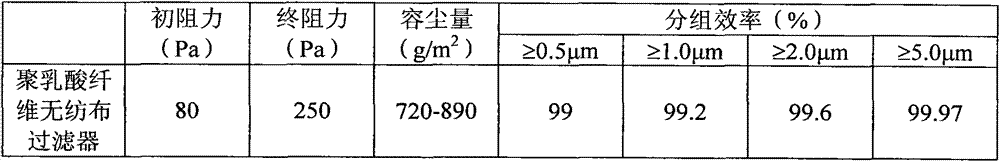

Examples

Embodiment Construction

[0024] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0025] The description of the source of stiff finishing agent, waterproofing agent and polylactic acid fiber should not be construed as limiting the content of the present invention, wherein:

[0026] Environmentally friendly stiffener polyvinyl acetate, model G-YT, purchased from Wuxi Yicheng Chemical Co., Ltd.; environmentally friendly stiffener polyacrylate, model DT-412, purchased from Foshan Yimei Chemical Co., Ltd.; environmentally friendly stiffener polyurethane , model DM-3561, purchased from Guangdong Demei Fine Chemical Co., Ltd.;

[0027] Waterproofing agent organic fluorine reagent, model TG410, purchased from Chuanhua Group Co., Ltd.; waterproofing agent silicone reagent, model SG-5, purchased from Jiaxing Huasheng Auxiliary Industry Company;

[0028] Polylactic acid staple fibers can be purchased in the market from manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com