Preparation method for coal/polyethyleneimine crosslinked composite chelate adsorbent

A polyethyleneimine, chelating adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment and other directions, can solve the problems of high manufacturing cost and complexity, and achieve low price and production technology Simple, controllable production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

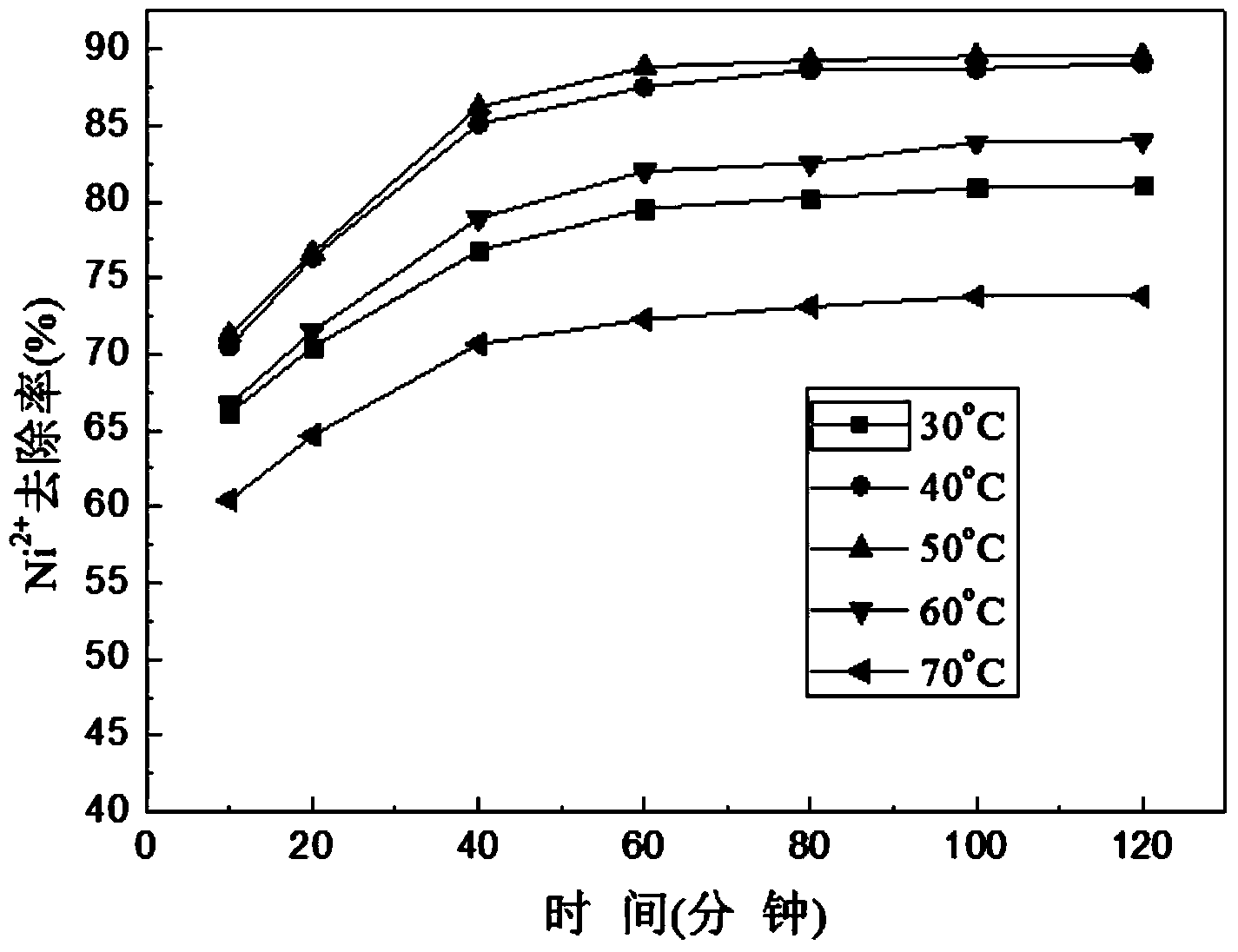

[0025] With 120g lignite coal powder as raw material, the method for preparing coal / polyethyleneimine cross-linked composite chelating adsorbent is realized by the following steps:

[0026] (1) Preparation of ultrafine coal powder

[0027] Take lignite and crush it into pulverized coal with a particle size of about 0.1-1mm, take 120g, deash with 0.1mol / L hydrochloric acid for 30min, add 3.6g of γ-aminopropyltriethoxysilane (KH550) as a coupling agent, coal The mass ratio of powder to γ-aminopropyltriethoxysilane is 1:0.03, stir and mix thoroughly, put into a ball mill and mill for 5 hours to obtain coal powder with a particle size of 0.1-5 μm.

[0028] (2) Grafting reaction

[0029] Take 5g of coal powder with a particle size of 0.1-5μm after ball milling, add 10ml of polyethyleneimine aqueous solution with a mass concentration of 1.5%, and the mass ratio of coal powder with a particle size of 0.1-5μm to polyethyleneimine is 1:0.03 , stirred and reacted for 3 hours in a wate...

Embodiment 2

[0033] With 120g lignite coal powder as raw material, the method for preparing coal / polyethyleneimine cross-linked composite chelating adsorbent is realized by the following steps:

[0034] (1) Preparation of ultrafine coal powder

[0035] Take lignite and crush it into coal powder with a particle size of 0.1-1mm, take 120g, deash with 0.1mol / L hydrochloric acid for 30min, add 1.2g of γ-aminopropyltriethoxysilane (KH550) as coupling agent, coal powder The mass ratio of γ-aminopropyltriethoxysilane to γ-aminopropyltriethoxysilane is 1:0.01, fully stirred and mixed, put into a ball mill and milled for 5 hours to obtain coal powder with a particle size of 0.1-5 μm.

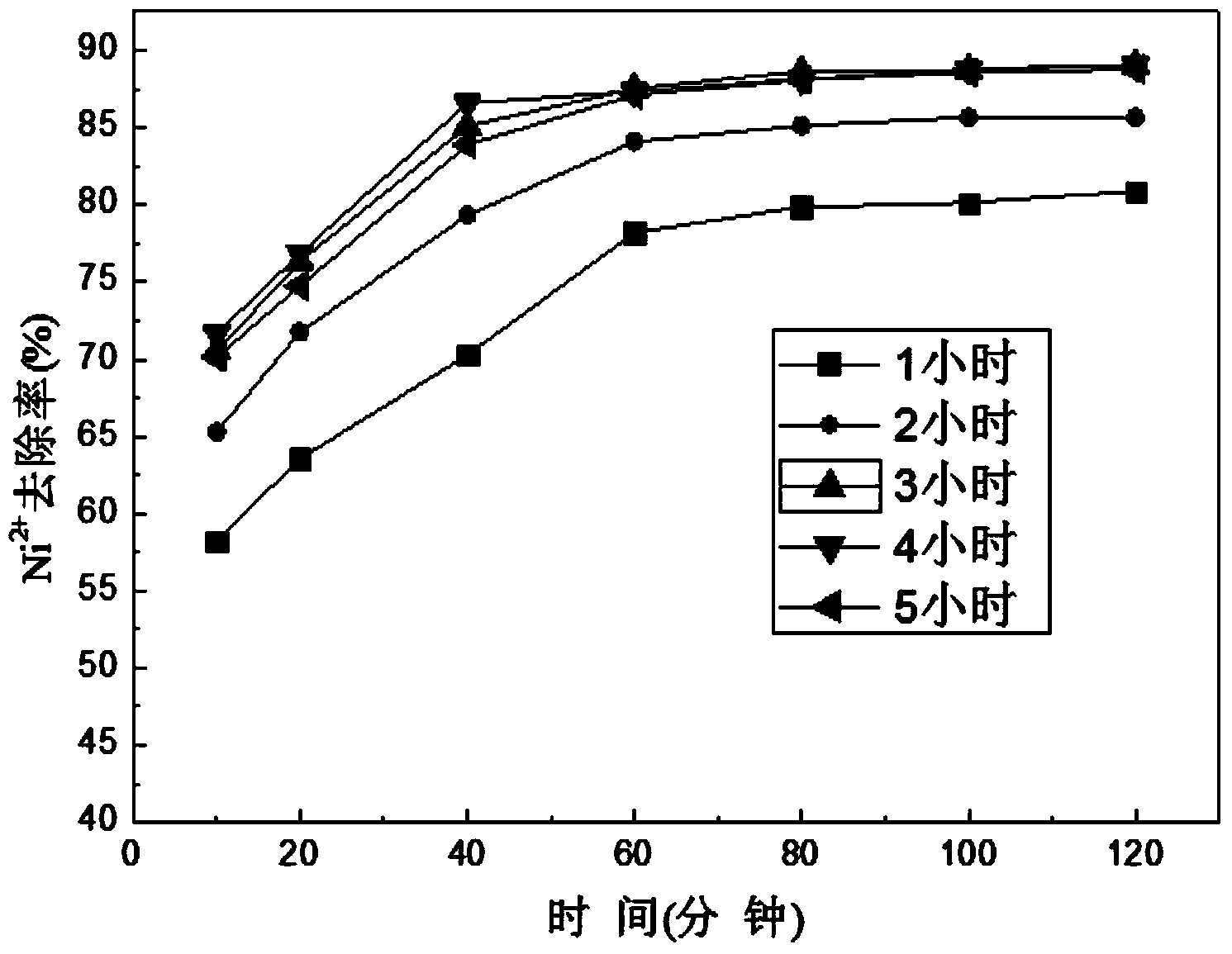

[0036] (2) Grafting reaction

[0037] Take 5g of coal powder with a particle size of 0.1-5μm after ball milling, add 6.67ml of polyethyleneimine aqueous solution with a mass concentration of 1.5%, and the mass ratio of coal powder with a particle size of 0.1-5μm to polyethyleneimine is 1: 0.02, stirred and reacted ...

Embodiment 3

[0041] With 120g lignite coal powder as raw material, the method for preparing coal / polyethyleneimine cross-linked composite chelating adsorbent is realized by the following steps:

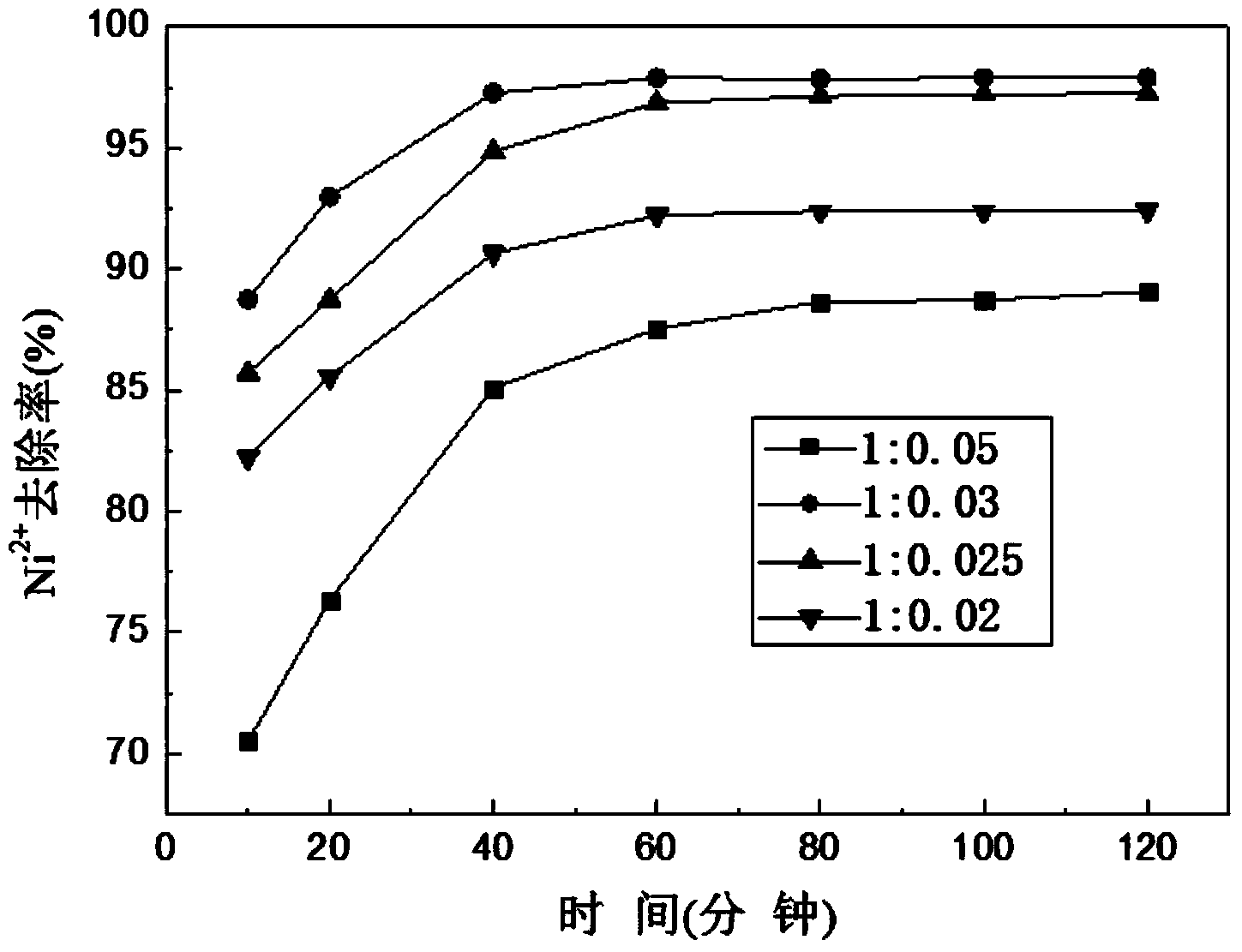

[0042] (1) Preparation of ultrafine coal powder

[0043] Take lignite and crush it into pulverized coal with a particle size of 0.1-1mm, take 120g, deash with 0.1mol / L hydrochloric acid for 30min, add 6.0g of γ-aminopropyltriethoxysilane (KH550) as coupling agent, coal powder The mass ratio of γ-aminopropyltriethoxysilane to γ-aminopropyltriethoxysilane is 1:0.05, fully stirred and mixed, put into a ball mill and milled for 5 hours to obtain coal powder with a particle size of 0.1-5 μm.

[0044] (2) Grafting reaction

[0045] Take 5g of coal powder with a particle size of 0.1-5μm after ball milling, add 16.67ml of polyethyleneimine aqueous solution with a mass concentration of 1.5%, and the mass ratio of coal powder with a particle size of 0.1-5μm to polyethyleneimine is 1: 0.05, stirred and rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com