Large-size block La2Zr2O7 ceramic material and hot pressed sintering preparation process thereof

A ceramic material, hot pressing sintering technology, applied in the field of ceramic materials, can solve the problems of limiting the preparation of large-size ceramics, less research on ceramic insulation materials, difficult to form thermal stress, etc., to achieve good thermal insulation performance and reliable mechanical bearing performance, Good thermal and mechanical properties, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

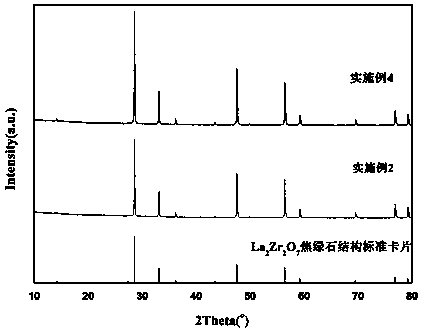

Examples

preparation example Construction

[0032] 1) La 2 Zr 2 o 7 Preparation of powder raw materials: Mix the aqueous solutions of lanthanum nitrate and zirconium oxychloride with a concentration of 0.1~1mol / L and stir for 1h to form La 3+ with Zr 4+ For a mixed solution with a molar ratio of 1:1, add the mixed solution dropwise to the ammonia water precipitant at a rate of 10~60ml / min, continue to stir for 2 hours after the dropwise addition, and then leave it to stand for 24 hours. After standing, the pH of the supernatant When the pH value of the supernatant reaches 10~13, wash and separate with deionized water. When the pH value of the supernatant is 7, wash and separate with ethanol, and dry at 80°C for 24 hours to obtain an amorphous powder. Grind the amorphous powder for 1 hour. Heat treatment at 650~800°C for 4 hours and pass through a 300-mesh screen to obtain a particle size of La 2 Zr 2 o 7 powder raw material;

[0033] 2) Hot pressing and sintering molding: towards La 2 Zr 2 o 7 Add alcohol with...

Embodiment 1

[0037] 1) La 2 o 3 and ZrO 2 The preparation of the mixed powder raw material: La with a particle size of 1 μm is weighed with a La:Zr molar ratio of 1 2 o 3 and ZrO 2 , fully mixed with alcohol as the medium in the tank mill, fully mixed by the impact of zirconium balls and then fully dried, and the dry powder was sieved to obtain a uniformly mixed micron-sized mixed powder.

[0038] 2) Hot press sintering molding: add alcohol with a mass ratio of 8% to the micron-sized mixed powder for granulation to obtain granulated powder, prefabricate the granulated powder into a square green body, put the green body into a sintering mold, At room temperature, apply an initial pressure to the biscuit through the pressure head to prevent material from running out during heating. The initial pressure is 10MPa. When the pressure is kept constant, the temperature is raised to 850°C at a heating rate of 5°C / min. Keep warm for 30 minutes, keep warm at 1350°C for 10 minutes, keep warm at 1...

Embodiment 2

[0041] 1) La 2 o 3 and ZrO 2 The preparation of the mixed powder raw material: take the La:Zr molar ratio as 1 and weigh the La with a particle size of 50nm 2 o 3 and ZrO 2 , fully mixed with alcohol as the medium in the tank mill, fully mixed by the impact of zirconium balls and then fully dried, and the dried powder was sieved to obtain uniformly mixed nano-scale mixed powder.

[0042]2) Hot press sintering molding: add alcohol with a mass ratio of 3% to the nano-scale mixed powder for granulation to obtain granulated powder, preform the granulated powder into a circular green body, and put the green body into a sintering mold At room temperature, the initial pressure is applied to the biscuit through the pressure head to prevent the material from running out during heating. The initial pressure is 30MPa. When the pressure is kept constant, the temperature is raised to 950°C at a heating rate of 10°C / min and kept for 30min. Insulate at 1250°C for 40 minutes, at 1350°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com