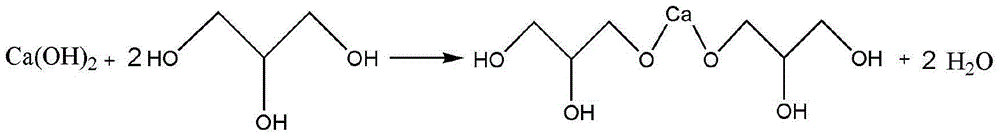

A method for homogeneously synthesizing calcium glycerol

A technology of calcium glycerol and glycerin, which is applied in the preparation of metal alcohols, organic chemistry, etc., can solve the problems of high energy consumption and low purity of calcium glycerol, and achieve the effects of solving the waste of excess resources, easy operation, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 1 g of calcium oxide and dissolve it in 200 ml of deionized water, filter off the precipitate to obtain a saturated solution of calcium hydroxide. Measure 100ml calcium hydroxide saturated solution and 10ml glycerol (volume ratio 1:0.1) and mix, stir evenly and heat to 30°C, react at 30°C under reflux for 2h, after the reaction, cool the reaction product to room temperature. After washing with ethanol and suction filtration for several times, the solid product was vacuum-dried at 80°C to constant weight, and the obtained white powder was calcium glycerol.

Embodiment 2

[0025] Weigh 1 g of calcium oxide and dissolve it in 200 ml of deionized water, filter off the precipitate to obtain a saturated solution of calcium hydroxide. Measure 100ml calcium hydroxide saturated solution and 50ml glycerol (volume ratio 1:0.5) and mix, stir evenly and heat to 30°C, react at 30°C under reflux for 4h, after the reaction, cool the reaction product to room temperature. After washing with ethanol and suction filtration for several times, the solid product was vacuum-dried at 80°C to constant weight, and the obtained white powder was calcium glycerol.

Embodiment 3

[0027] Weigh 1 g of calcium oxide and dissolve it in 200 ml of deionized water, filter off the precipitate to obtain a saturated solution of calcium hydroxide. Measure 100ml calcium hydroxide saturated solution and 100ml glycerin (volume ratio 1:1) and mix, stir evenly and heat to 50°C, react at 50°C under reflux for 4h, after the reaction, cool the reaction product to room temperature. After washing with ethanol and suction filtration for several times, the solid product was vacuum-dried at 80°C to constant weight, and the obtained white powder was calcium glycerol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com