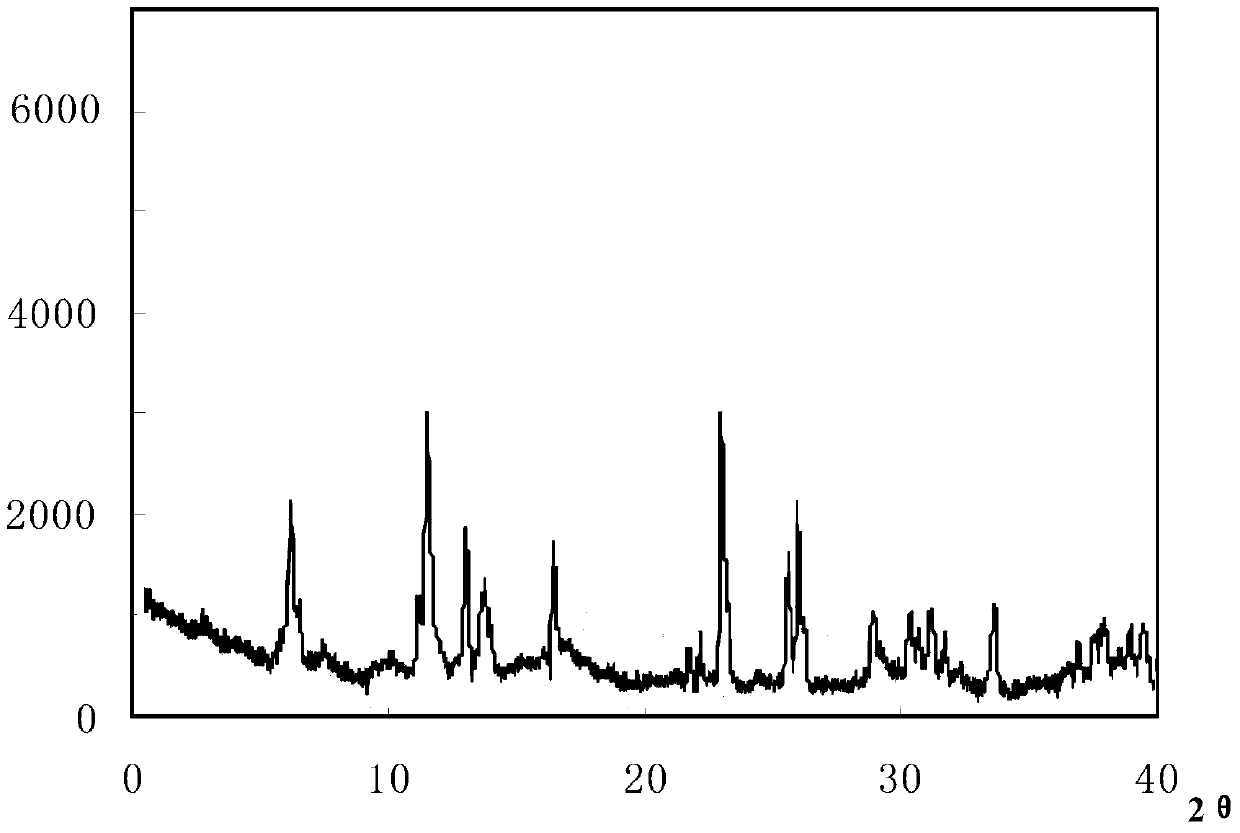

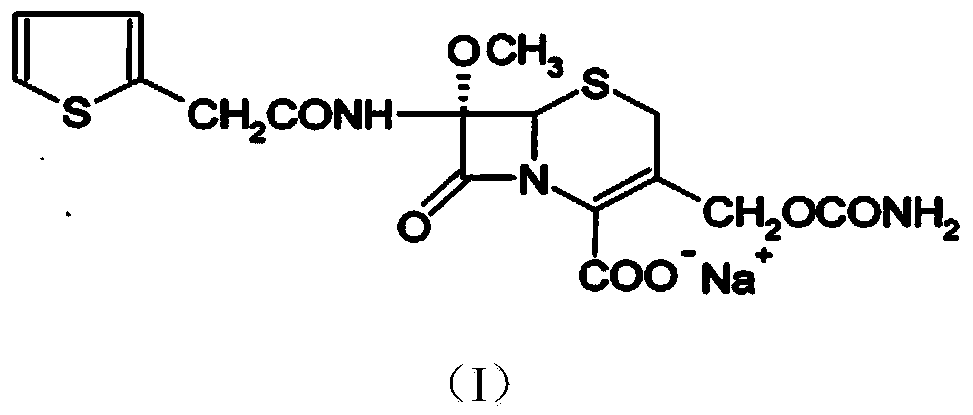

Cefoxitin sodium compound and preparation method thereof

A technology of cefoxitin sodium and crystal compounds, which is applied in the field of medicine, can solve problems such as detection of hygroscopicity of cefoxitin sodium crystals, and achieve the effects of high purity, high yield, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of cefoxitin sodium crystalline compound

[0030] 1. Prepare 5 L of saturated aqueous solution of cefoxitin sodium crude product at 65°C;

[0031] 2. Prepare 15L of mixed organic solvent of acetone, ether and acetonitrile; the volume ratio of acetone, ether and acetonitrile in the mixed organic solvent is 3:2:1;

[0032] 3. Cool the organic solvent to 0°C. Under the sound field with a frequency of 25KHz and an output power of 40W, add the saturated aqueous solution of crude cefoxitin sodium to the organic solvent at a constant speed while stirring, and the addition speed is 3 liters / hour; the stirring speed The temperature is 480 rpm; after the addition, continue to stir and cool down, the stirring speed is 240 rpm; stop stirring after cooling down to 0-5 °C, and the cooling rate is 1 °C / hour. Static growth of crystals for 4 hours; after obtaining crystals, filter, wash with absolute ethanol, and vacuum dry for 6 hours to obtain cefoxitin sodi...

Embodiment 2

[0034] Embodiment 2: Preparation of cefoxitin sodium crystal compound

[0035] 1. Prepare 5 L of saturated aqueous solution of cefoxitin sodium crude product at 60°C;

[0036] 2. Prepare 30L mixed organic solvent of acetone, ether and acetonitrile; the volume ratio of acetone, ether and acetonitrile in the mixed organic solvent is 2:1:1;

[0037]3. Cool the organic solvent to 5°C, under a sound field with a frequency of 25KHz and an output power of 80W, add the saturated aqueous solution of crude cefoxitin sodium to the organic solvent at a constant speed while stirring, and the addition speed is 6 liters / hour; the stirring speed The temperature is 480 rpm; after the addition, continue to stir and cool down, the cooling rate is 2°C / hour, and the stirring speed is 120 rpm; stop stirring after cooling down to 1°C; stand for crystal growth for 6 hours; filter after obtaining crystals, Wash with absolute ethanol, and vacuum-dry for 6 hours to obtain cefoxitin sodium crystalline c...

Embodiment 3

[0039] Embodiment 3: Preparation of cefoxitin sodium crystal compound

[0040] 1. Prepare 5 L of saturated aqueous solution of cefoxitin sodium crude product at 68°C;

[0041] 2. Prepare 20L of mixed organic solvent of acetone, ether and acetonitrile, the volume ratio of acetone, ether and acetonitrile in the mixed organic solvent is 3:1:1;

[0042] 3. Cool the organic solvent to 2°C. Under the sound field with a frequency of 25KHz and an output power of 60W, add the saturated aqueous solution of crude cefoxitin sodium to the organic solvent at a constant speed while stirring, and the addition speed is 2 liters / hour; the stirring speed The temperature is 240 rpm; after the addition, continue to stir and cool down, the cooling rate is 2°C / hour; the stirring speed is 120 rpm; stop stirring after cooling down to 1°C; let the crystal grow for 4 hours; filter after obtaining the crystal, Wash with absolute ethanol, and vacuum-dry for 6 hours to obtain cefoxitin sodium crystalline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com