Coating rubber sizing material of dual-purpose printing rubber roller for UV (ultraviolet) ink and common ink

A technology for printing rubber rollers and coating rubber, which is applied in the field of rubber coating materials, and can solve the problems of inability to take into account the interchangeability, large swelling and large swelling of UV printing rubber rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

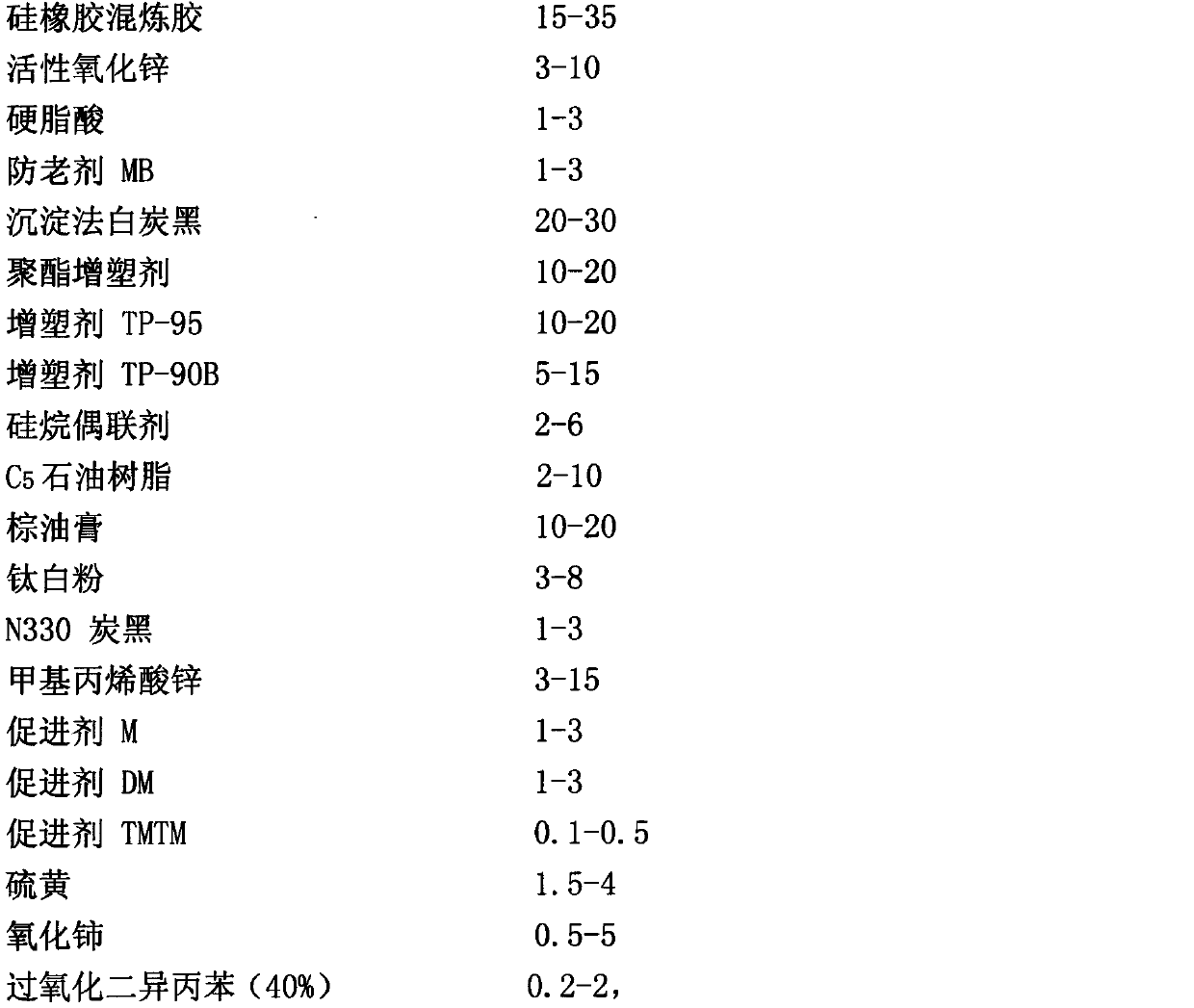

[0019] The sizing material formula of embodiment 1 and the quality proportioning of various raw materials are as follows:

[0020]

[0021] The preparation of embodiment 1 sizing material: first prepare respectively the master batch of preplasticized nitrile rubber / polyvinyl chloride blend (hereinafter referred to as master batch N) and the master batch of silicone rubber compound rubber (hereinafter referred to as master batch S) , Then masterbatch N and masterbatch S were blended in proportion to prepare the compound of Example 1. ①Preparation of masterbatch N: In the above formula, except for the silicone rubber compound, cerium oxide and dicumyl peroxide, other raw materials are measured according to the mass ratio, and then the blend rubber (1234E) is added to the internal mixer in sequence. , small materials (zinc oxide, stearic acid, anti-aging agent), other compounding agents (white carbon black, zinc methacrylate, coupling agent, titanium dioxide, carbon black, oin...

Embodiment 2

[0024] The sizing material formula of embodiment 2 and the quality proportioning of various raw materials are as follows:

[0025]

[0026] The preparation of embodiment 2 sizing material: 1. masterbatch N: same as embodiment 1; 2. masterbatch S: batching mass ratio is R701 / 8030, R701 / 4070, cerium oxide 10, dicumyl peroxide (40%) 2.5 , the rest of the operations are the same as in Example 1; ③ masterbatch blending: the mass ratio of the ingredients is masterbatch N312.15 and masterbatch S33.75, and the rest of the operations are the same as in Example 1.

[0027] The shaping of rubber roller, vulcanization and post-processing are identical with embodiment 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com