A kind of phase change material microcapsule with aromatic smell and preparation method thereof

A technology of phase change materials and aromatic odor, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., and can solve the incompatibility between isophorone diisocyanate and paraffin hydrocarbons, and the odor of phase change material microcapsules, etc. problems, to achieve the effect of high mechanical strength, comfortable mood, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

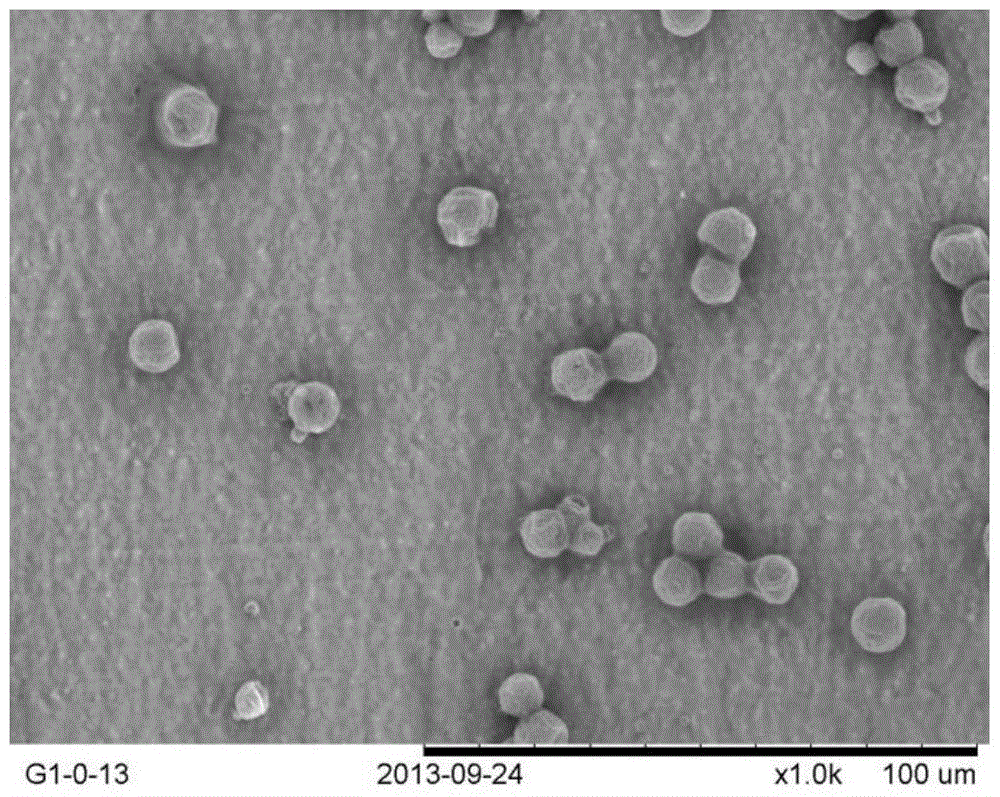

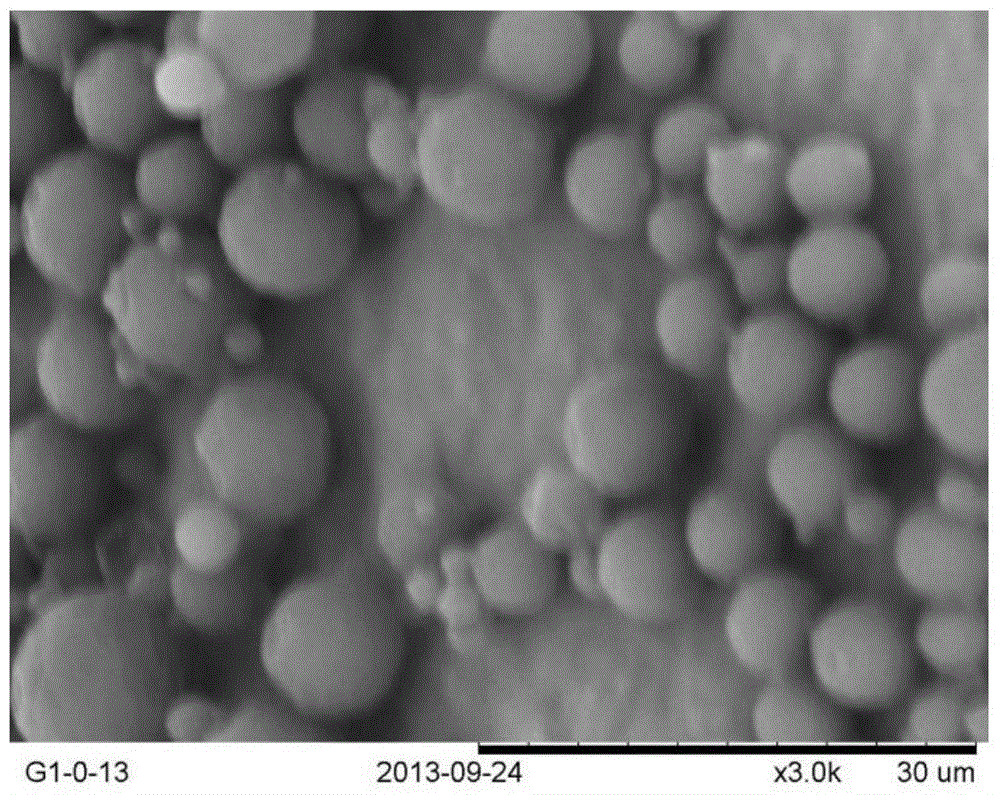

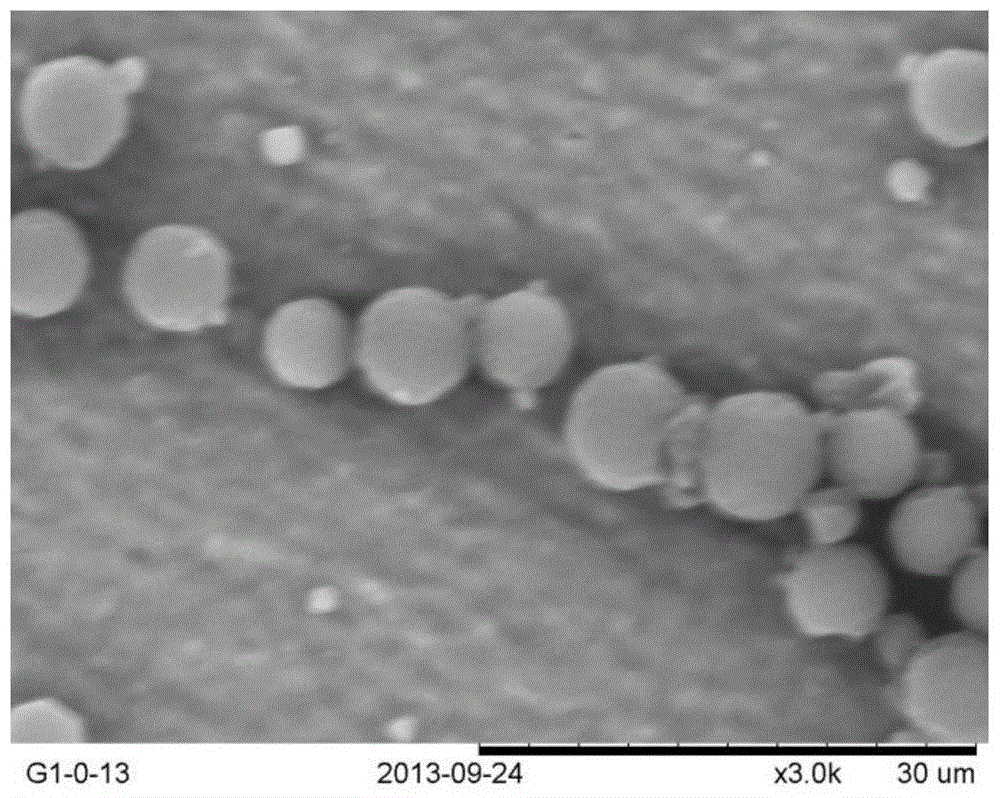

Image

Examples

Embodiment 1

[0045] (1) Preparation of water phase

[0046] Weigh 6.0 g of emulsifier into a beaker, add deionized water to 100 g, stir for 2 h under the action of a magnetic stirrer to completely dissolve the emulsifier, and prepare a 6 wt % emulsifier aqueous solution for later use. Add 16.6g of emulsifier aqueous solution into a 100ml beaker, then add 46.6g of deionized water, stir well to obtain the water phase;

[0047] (2) Preparation of oil phase

[0048] Add 3.2g of diisocyanate into a 100ml beaker, then add 7.5g of peppermint oil, stir until completely miscible, then add 22.5g of n-tetradecane, completely miscible at 25°C to obtain an oil phase;

[0049] (3) Formation of emulsion

[0050] Heat the water phase and oil phase at 25°C for 3 minutes, add the oil phase to the water phase while it is hot, and shear at a high speed for 3 minutes under the action of a homogenizer at 6600 rpm to form an oil-in-water emulsion;

[0051] (4) Formation of microcapsules

[0052] Add 3.6g of ...

Embodiment 2

[0055] (1) Preparation of water phase

[0056]Weigh 6.0 g of emulsifier into a beaker, add deionized water to 100 g, stir for 2 h under the action of a magnetic stirrer to completely dissolve the emulsifier, and prepare a 6 wt % emulsifier aqueous solution for later use. Add 16.6g of emulsifier aqueous solution into a 100ml beaker, then add 46.6g of deionized water, stir evenly to obtain the water phase;

[0057] (2) Preparation of oil phase

[0058] Add 3.2g of diisocyanate into a 100ml beaker, then add 7.5g of peppermint oil, stir until completely miscible, then add 22.5g of n-hexadecane, completely miscible at 25°C to obtain an oil phase;

[0059] (3) Formation of emulsion

[0060] Heat the water phase and oil phase at 25°C for 3 minutes, add the oil phase to the water phase while it is hot, and shear at a high speed for 3 minutes under the action of a homogenizer at 6600 rpm to form an oil-in-water emulsion;

[0061] (4) Formation of microcapsules

[0062] Add 3.6g of ...

Embodiment 3

[0065] (1) Preparation of water phase

[0066] Weigh 6.0 g of emulsifier into a beaker, add deionized water to 100 g, stir for 2 h under the action of a magnetic stirrer to completely dissolve the emulsifier, and prepare a 6 wt % emulsifier aqueous solution for later use. Add 16.6g of emulsifier aqueous solution into a 100ml beaker, then add 46.6g of deionized water, stir evenly to obtain the water phase;

[0067] (2) Preparation of oil phase

[0068] Add 3.2g of diisocyanate into a 100ml beaker, then add 7.5g of mint oil, stir until completely miscible, then add 22.5g of n-octadecane, completely miscible at 30°C, to obtain an oil phase;

[0069] (3) Formation of emulsion

[0070] Heat the water phase and oil phase at 30°C for 3 minutes, add the oil phase to the water phase while it is hot, and shear at a high speed for 3 minutes under the action of a homogenizer at 6600 rpm to form an oil-in-water emulsion;

[0071] (4) Formation of microcapsules

[0072] Add 3.6g of 40wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com