Method for decomposing scheelite

A technology of scheelite and extraction, applied in the direction of improving process efficiency, etc., can solve the problems of hindered diffusion, slow down the speed of reaction, and difficulty in phase separation, and achieve the effects of wide application, increased concentration, and simple extraction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

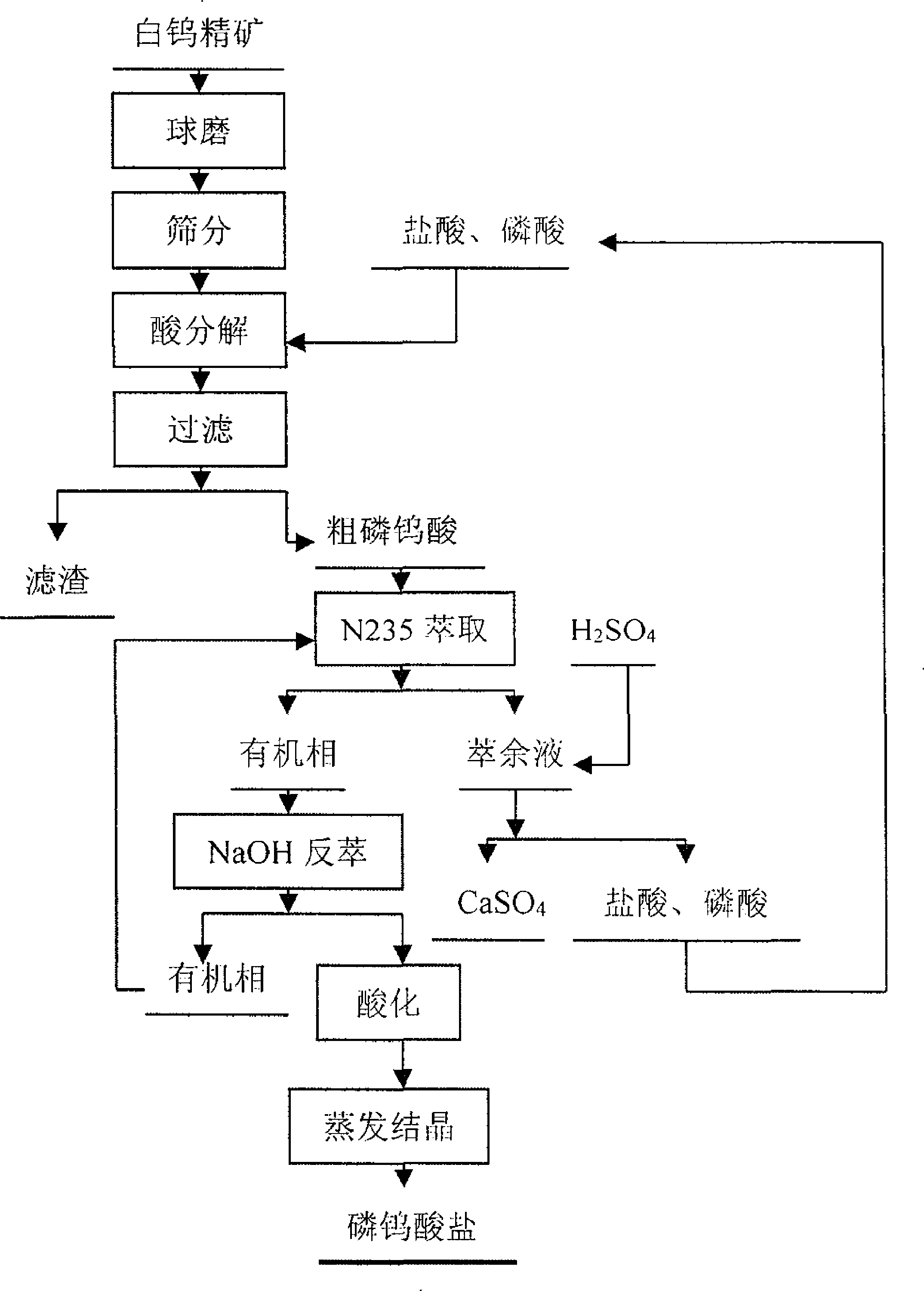

Method used

Image

Examples

specific Embodiment approach

[0022] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in further detail below in conjunction with specific embodiments:

[0023] Weigh 10g of scheelite with a particle size grade of (+300 mesh, -250 mesh), add 2mol L-1 hydrochloric acid 100mL and the same amount of phosphoric acid m w / m po4 3- =3:1, the decomposition temperature is 90°C, the decomposition time is 2.5h, the stirring speed is 900 rpm, and the leaching rate of tungsten ore is 99.6%. Then use a volume ratio of 12% N235, 20% n-octanol, and 68% kerosene as the organic relative tungsten decomposition liquid for extraction. The ratio is 1:1, and the mixing time is 5 minutes. The extraction rate of tungsten can reach 99.90%. Using 50ml and 1.5mol / L NaOH solution in a ratio of 1:1, the stripping rate can reach 98%. The organic phase of stripping is recycled and used. After stripping, the liquid water bath is heated to 40°C, and then hydrochloric acid is added dropwise to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com