Manufacturing method for high-performance composite yarn

A composite yarn, high-performance technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of poor mechanical properties, poor cohesion of composite yarns, low elastic modulus, enhanced cohesion and cohesion, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

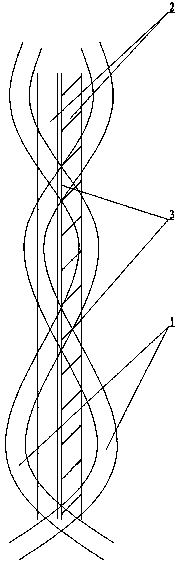

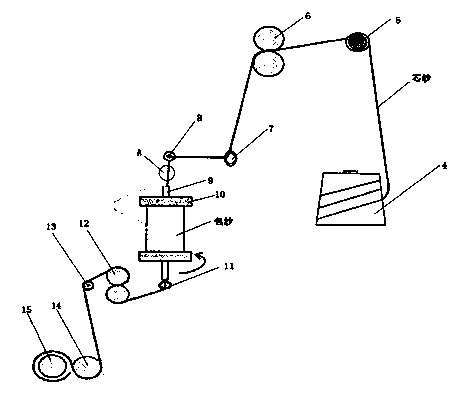

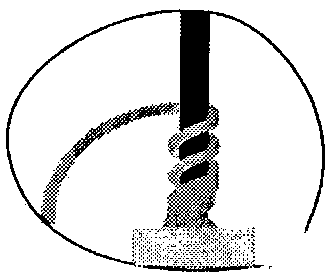

[0033] The high-performance composite yarn of this embodiment combines figure 1 , including twisted covered yarn 1 and twistless core yarn 2, covered yarn 1 is wound on the outer layer of core yarn 2 in a twistless and combined manner, and there are network points 3 on the composite yarn, and the twist of the network point 3 and covered yarn 1 ( figure 1 The twist distance d) is the same, which is used to enhance the cohesion of the composite yarn. Among them, the reinforcing fiber is basalt fiber with a fineness of 330tex; the matrix fiber is polypropylene with a fineness of 100tex; the mass ratio of the reinforcing fiber to the matrix fiber is 3.3:1. Combine two fibers without twist, where:

[0034] (1) Mixing 0.3 parts by mass of matrix fiber with 3.3 parts by mass of reinforcing fiber, the mixing method is twistless and combined, evenly mixed to form a twistless core yarn;

[0035] (2) Twisting the remaining 0.7 parts of the base fiber to form a twisted wrapped yarn, th...

Embodiment 2

[0045] In the composite yarn prepared in this embodiment, the wrapped yarn 1 is polypropylene, that is, the base fiber is polypropylene, the fineness of polypropylene fiber is 100tex, the reinforcing fiber is glass fiber, and the fineness of glass fiber is 270tex. The mass ratio of glass fiber to polypropylene fiber is It is 2.7:1, the two fibers are combined without twisting, where:

[0046] (1) Mixing 0.25 parts by mass of matrix fiber with 2.7 parts by mass of reinforcing fiber, the mixing method is untwisted and combined, evenly mixed to form a twistless core yarn;

[0047] (2) Twisting the remaining 0.75 parts of the matrix fiber to form a twisted wrapped yarn, the twist of the wrapped yarn is 50 twists / 10cm, and the twist direction is Z-shaped;

[0048] (3) Utilize the processing method of air-jet network, control the air-jet pressure to 0.24MPa, and the upper machine tension to 0.27N, entangle the two kinds of monofilaments with each other to form a glass / polypropylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com