Online continuous dehydration and deoxidation method for aviation fuel oil

An aerospace and fuel technology, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve the problems of reducing heat exchange wall heat exchange, long time, affecting engine oil supply, etc., and achieves good mixing performance and operation. High elasticity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention is further illustrated by the following examples. The embodiments are illustrative only, not restrictive.

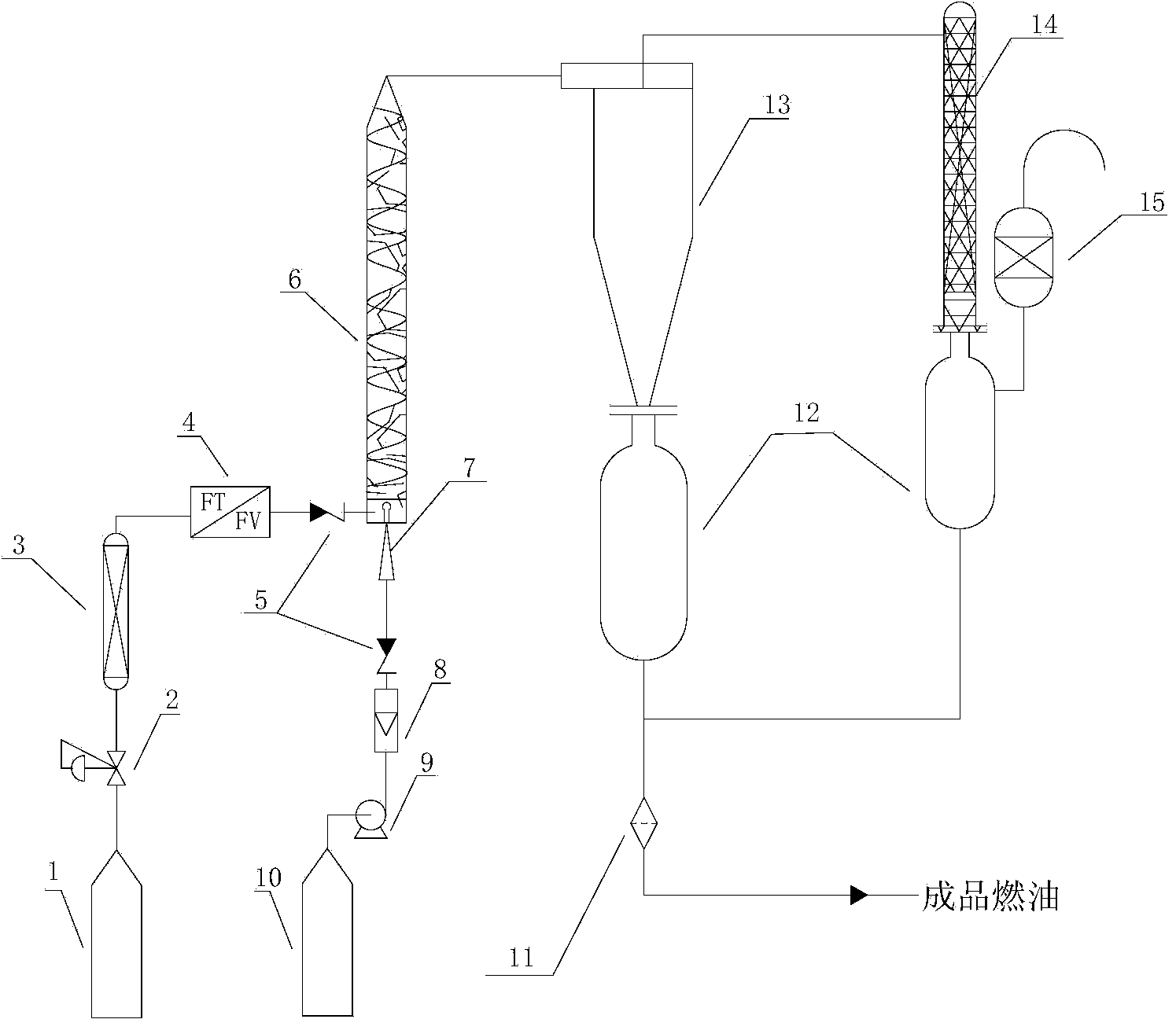

[0024] use figure 1 The described procedure was carried out for experimentation. The aerospace fuels to be treated are aviation kerosene (RP-3), high-density hydrocarbon HD-01 and rocket kerosene, which contain dissolved oxygen and dissolved water. The dissolved oxygen and dissolved water before treatment are shown in Table 1.

[0025] After the aerospace fuel to be processed is pressurized by the fuel inlet pump 9, the fuel is atomized into mist droplets through the atomizing nozzle 7 after flowing through the liquid flow meter 8 to measure the flow rate, and sprayed into the static pipeline mixer 6 . At the same time, the nitrogen gas 1 is decompressed by the pressure reducing valve 2, and then flows through the gas dryer to reduce the water content carried in the nitrogen gas to less than 50ppm. Then, after adjusting the nitrogen flow rate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com