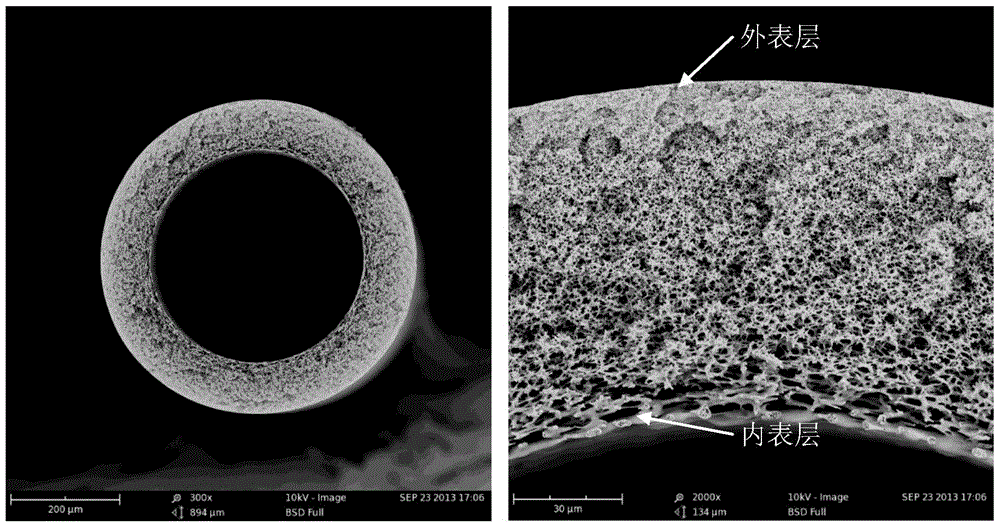

A kind of superhydrophilic gradient hole hollow fiber membrane and its preparation method

A gradient pore, fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. problems, to achieve the effect of reducing resistance, reducing water penetration resistance, and avoiding hydrophilic attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

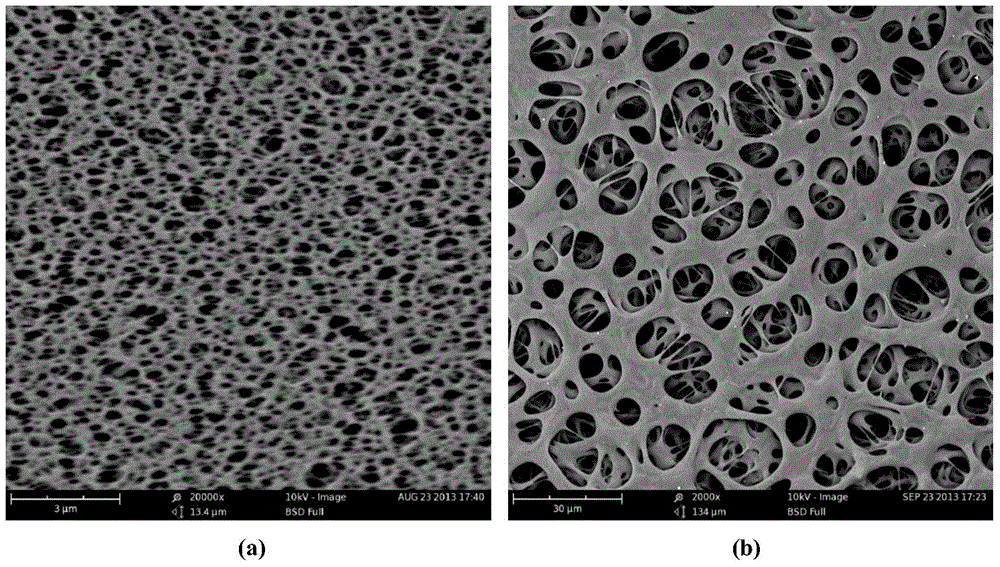

Method used

Image

Examples

Embodiment 1

[0044] 12wt% polyvinylidene fluoride, 5wt% amphiphilic block polyether modified silicone (wherein the number of repeating chains n of the polysiloxane chain segment is 500, the number of repeating chains m and p of the polyether chain segment is equal to 900), 12wt% PEG1000, 5wt% PVP-K90, 1wt% water and 65wt% DMF were mixed, stirred and dissolved at 50°C for 24 hours, and then defoamed for 12 hours to obtain the casting solution for later use. With DMF: NMP: water is 50wt%: 10wt%: 40wt% mixed solution is injection spinneret for core liquid, with DMF: NMP: water is 40wt%: 10wt%: 50wt% mixed solution is outer gel liquid, casting The film liquid is extruded from the spinneret under 500kPa and immersed in the outer gel liquid. During the spinning process, the temperature of the core liquid and the outer gel liquid are controlled to be 70°C and 55°C respectively, and the casting liquid forms primary fibers under the action of the core liquid and the outer gel liquid, which are then...

Embodiment 2

[0046] 13wt% polysulfone, 5wt% amphiphilic block polyether modified silicone (wherein the number of repeating chains n of the polysiloxane segment is 10000, the number of repeating chains m and p of the polyether segment are both 600 ), 15wt%PVP~17, 5wt%PVP-K90, 8wt% water and 54wt%DMAc were mixed, stirred and dissolved at 50°C for 24h, and then defoamed for 12h to obtain the casting solution for later use. Take DMAc: NMP: water as 10wt%: 50wt%: 40wt% mixed solution as the core liquid injection spinneret, with DMAc: NMP: water as 10wt%: 45wt%: 45wt% mixed solution as the outer gel liquid, cast The film liquid is extruded from the spinneret under 500kPa and immersed in the outer gel liquid. During the spinning process, the temperature of the core liquid and the outer gel liquid are controlled to be 65°C and 55°C respectively, and the casting liquid forms primary fibers under the action of the core liquid and the outer gel liquid, and then rinses them in pure water for 48 hours....

Embodiment 3

[0048] 14wt% polyethersulfone, 5wt% amphiphilic block polyether modified silicone (wherein the number of repeating chains n of the polysiloxane segment is 1800, and the number of repeating chains m and p of the polyether segment are both 900), 16wt% PVP-K30, 6wt% water and 59wt% NMP were mixed, stirred and dissolved at 60°C for 20h, and then defoamed for 16h to obtain the casting solution for later use. With DMF: NMP: water is 20wt%: 60wt%: 20wt% mixed solution is injection spinneret for core liquid, with DMF: NMP: water is 10wt%: 50wt%: 40wt% mixed solution is outer gel liquid, casting The film liquid is extruded from the spinneret under 500kPa and immersed in the outer gel liquid. During the spinning process, the temperature of the core liquid and the temperature of the outer gel liquid are controlled to be 75°C and 60°C respectively, and the casting liquid forms the primary fiber under the action of the core liquid and the outer gel liquid, and then rinses it in pure water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com