Diatomite floor and production method thereof

A production method and technology of earth floor, which is applied in the field of diatom earth floor, can solve the problems such as short service life of diatom mud floor, and achieve the effect of preventing insects and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, specific embodiments of the present invention are further described.

[0017] The invention discloses a diatom mud floor and a manufacturing method thereof. The ratio of each component of the diatom earth floor is 150 kg of the diatom earth, 100 kg of the high molecular PVC material, 20 kg of the reinforcing agent CPE, and the Said glidant epoxy soybean oil 2kg, said stabilizer calcium stearate 8kg and said processing aid K-12310kg.

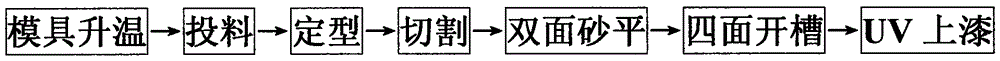

[0018] The manufacturing method of the diatomite floor, the step sequence of the manufacturing method is that the temperature of the mold is raised to 165 degrees Celsius, feeding, shaping, cutting, double-sided sanding, four-sided grooving and UV painting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com