Electrolyte material and preparation method for intermediate and low-temperature solid oxide fuel cells

A solid oxide and electrolyte material technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of difficulty in sintering, lowering the open circuit voltage of the battery, and high sintering temperature, and achieves enhanced electrical conductivity, increased open circuit voltage, and improved performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing an electrolyte material for a medium-low temperature solid oxide fuel cell, comprising the following steps: preparing by a sol-gel method, adding Sm(NO 3 ) 3 , In(NO 3 ) 3 , Ce(NO 3 ) 3 According to the proportion of the target product

[0018] In deionized water, make a mixed nitrate solution, add an appropriate amount of citric acid according to the total number of metal ions: the molar ratio of citric acid is 1: 1.5, and use ammonia water to adjust the pH value of the solution to about 7, and stir the clarified The precursor solution was evaporated on a heating platform at 100 °C to remove water to make it into a gel, and then placed in an electric furnace to burn to form a powdery solid precursor. Finally, the solid precursor was roasted in a muffle furnace at 600 °C for 3 hours to obtain the obtained Required Sm x In y Ce 1-x-y o 2-δ Electrolyte powder material.

[0019] Medium and low temperature solid oxide fuel cell electrolyte m...

Embodiment 1

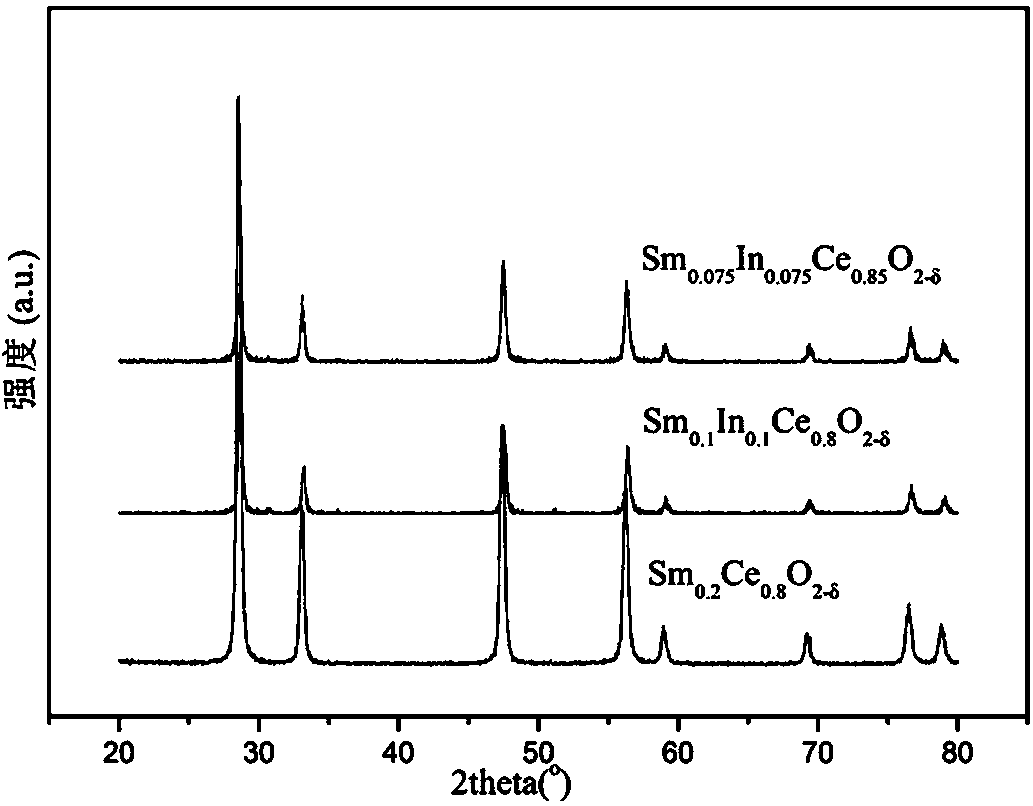

[0021] Prepared by sol-gel method, Sm(NO 3 ) 3 , In(NO 3 ) 3 , Ce(NO 3 ) 3 Dissolve in deionized water according to the proportion of the target product, and make a mixed nitrate solution, add an appropriate amount of citric acid according to the total number of metal ions: the molar ratio of citric acid is 1:1.5, and use ammonia water to adjust the pH value of the solution to about 7, The stirred and clarified precursor solution is evaporated on a heating platform at 100°C to remove water to make it into a gel, and then placed in an electric furnace to burn to form a powdery solid precursor, and finally the solid precursor is roasted in a muffle furnace at 600°C 3h, get the required Sm x In y Ce 1-x-y o 2-δ Electrolyte powder material, where 0.01figure 1 The XRD powder diffraction method shown shows that Sm x In y Ce 1-x-y o 2-δ A pure-phase fluorite structure is formed without other impurity phases.

[0022] The anode substrate is made of NiO, oxygen ion conduct...

Embodiment 2

[0025] Prepared by sol-gel method, Sm(NO 3 ) 3 , In(NO 3 ) 3 , Ce(NO 3 ) 3 Dissolve in deionized water according to the proportion of the target product, and make a mixed nitrate solution, add an appropriate amount of citric acid according to the total number of metal ions: the molar ratio of citric acid is 1:1.5, and use ammonia water to adjust the pH value of the solution to about 7, The stirred and clarified precursor solution is evaporated on a heating platform at 100°C to remove water to make it into a gel, and then placed in an electric furnace to burn to form a powdery solid precursor, and finally the solid precursor is roasted in a muffle furnace at 600°C 3h, get the required Sm x In y Ce 1-x-y o 2-δ Electrolyte powder material, where 0.01figure 1 The XRD powder diffraction method shown shows that Sm x In y Ce 1-x-y o 2-δ A pure-phase fluorite structure is formed without other impurity phases.

[0026] The anode substrate is made of NiO, oxygen ion conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com