A calcium-zinc composite heat stabilizer, a preparation method thereof and applications thereof

A composite heat stabilizer and reaction technology, which is applied in the direction of organic chemistry, can solve the problems of poor stability of calcium-zinc composite stabilizers, achieve good thermal stability effects, high-efficiency stable functions, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

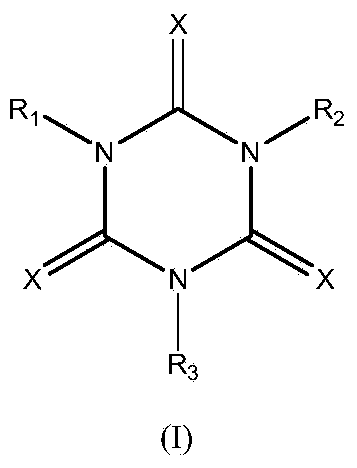

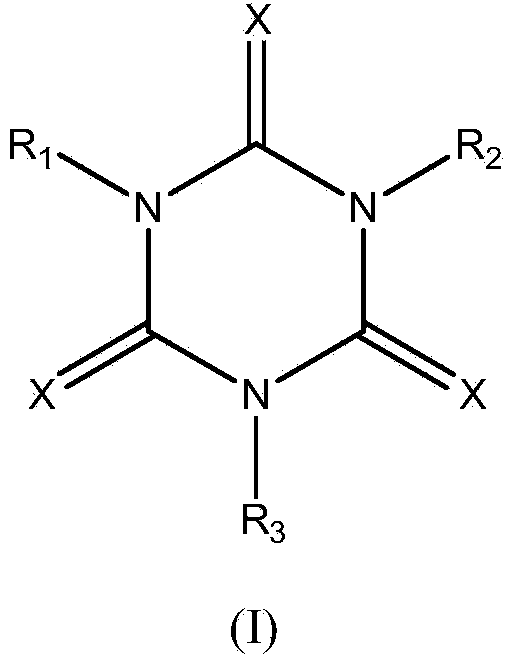

Image

Examples

Embodiment 1~4

[0026] Put 21.9g of zinc acetate dihydrate, 48.2g of bis(epoxypropyl)isocyanurate, and 150g of water into a reaction kettle, stir evenly, and reflux for 2 hours. During the reaction, a sodium hydroxide solution with a mass concentration of 10% was added dropwise to adjust the pH of the reaction mixture so that the pH was maintained at 7. After the reaction, cool to room temperature, filter, wash the filter cake with distilled water (200mL×3), put it in a blast oven, and dry it at 100°C to obtain the product zinc di(epoxypropyl)isocyanurate. Feed the prepared zinc bis(epoxypropyl)isocyanurate, calcium stearate, and various auxiliary stabilizers according to the formula ratio, and stir and mix in a high-speed mixer, stir and heat up to 100°C , stirring speed 60r / min, after stirring for 10min, the composite calcium-zinc heat stabilizer of the present invention was obtained, and the feed intake of each raw material is shown in Table 1.

[0027] Table 1 The raw material feeding am...

Embodiment 5~8

[0033]Put 143.5g of zinc sulfate heptahydrate, 38.7g of cyanuric acid, and 150g of water into the reaction kettle, stir evenly, and reflux for 2 hours. During the reaction, sodium hydroxide solution with a mass concentration of 10% was added dropwise to adjust the pH of the reaction mixture so that the pH was maintained at 9. After the reaction, cool to room temperature, filter, wash the filter cake with distilled water (300mL×3), put it in a blast oven, and dry it at 120°C for 2 hours to obtain the product basic zinc cyanurate. Feed the prepared basic zinc cyanurate, calcium stearate, and various auxiliary stabilizers according to the formula ratio, and stir and mix in a high-speed mixer, stir and heat up to 100°C, stir at a speed of 60r / min, and stir for 10min. The composite calcium-zinc heat stabilizer involved in the present invention is obtained, and the specific feeding amount of each raw material is shown in Table 3.

[0034] Table 3 The raw material feeding amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com