Graphene electrode plate and preparation method thereof

A graphene electrode, graphene technology, applied in the field of electrochemical materials, to achieve the effects of long life, increased capacity, and increased energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

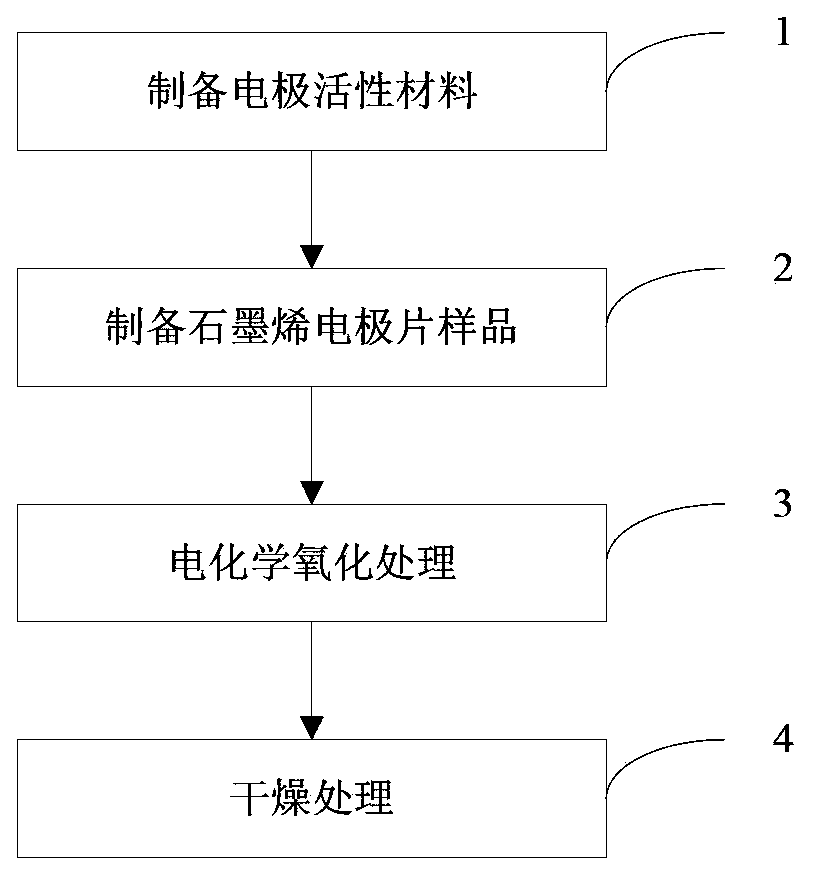

[0028] Graphene electrode sheet preparation method provided by the invention, such as figure 1 As shown, the process steps are as follows:

[0029] 1. Preparation of gel-like electrode active materials:

[0030] According to the mass percentage, add 90~96% graphene, 2~5% conductive agent, and 2~5% binder into the solvent, stir evenly, and configure a gel-like electrode active material: among them, the electrode active material In the material, the solvent accounts for 10-30% of the total weight:

[0031] The conductive agent includes acetylene black, Ketjen black, SP conductive carbon black: the binder includes polyvinylidene fluoride, polytetrafluoroethylene, polyvinyl alcohol: the solvent includes NMP, absolute ethanol:

[0032] 2. Preparation of graphene electrode sheet samples: uniformly coat the electrode active material on the current collector, and control the coating thickness to 50-300 μm, then put it into an oven and dry it at 80-100 ° C for 6-12 hours to obtain G...

Embodiment 1

[0039] 1. Preparation of gel-like electrode active materials:

[0040] According to the mass percentage, add 90% graphene, 5% acetylene black, and 5% polyvinylidene fluoride (PVDP) into the NMP solvent, stir evenly, and configure a gel-like electrode active material: among them, the electrode active material Among them, the solvent accounts for 30% of the total weight:

[0041] 2. Prepare graphene electrode sheet samples: Coat the electrode active material evenly on the aluminum foil, and control the coating thickness to 50 μm, then put it in an oven and dry it at 80°C for 12 hours to obtain graphene electrode sheet samples:

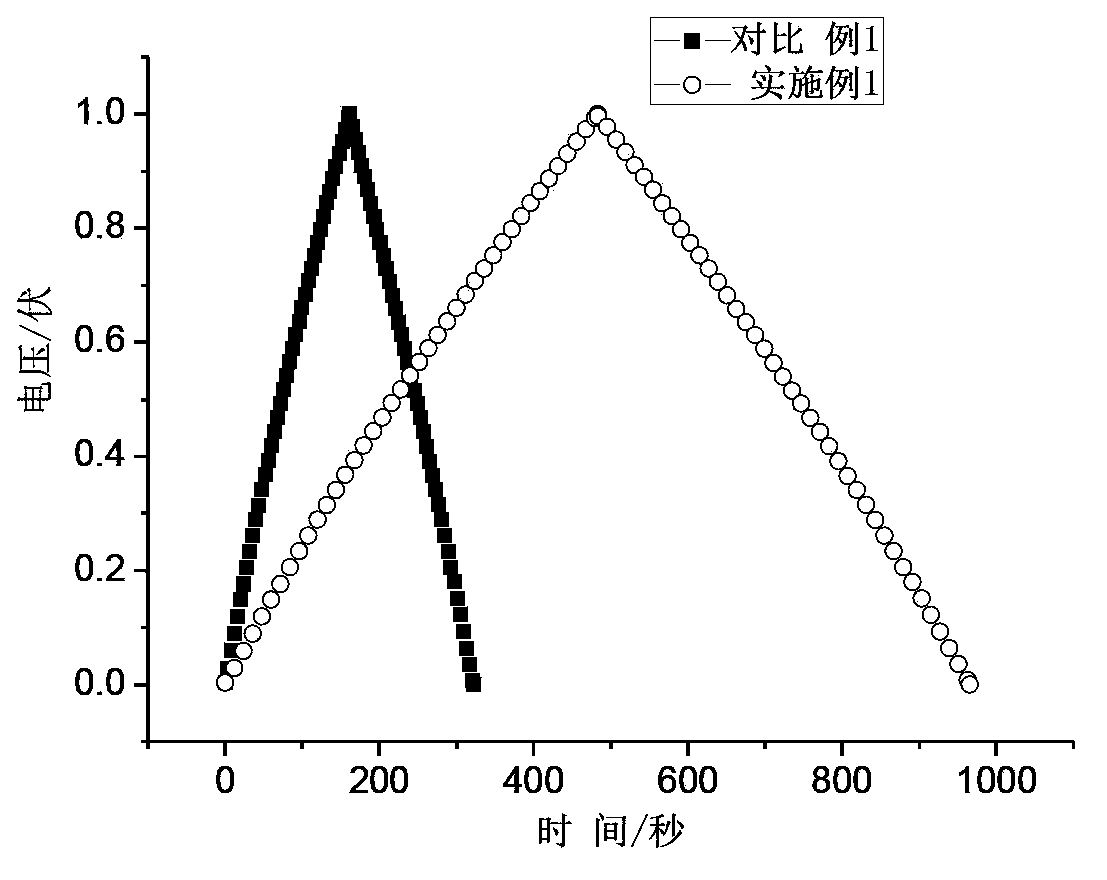

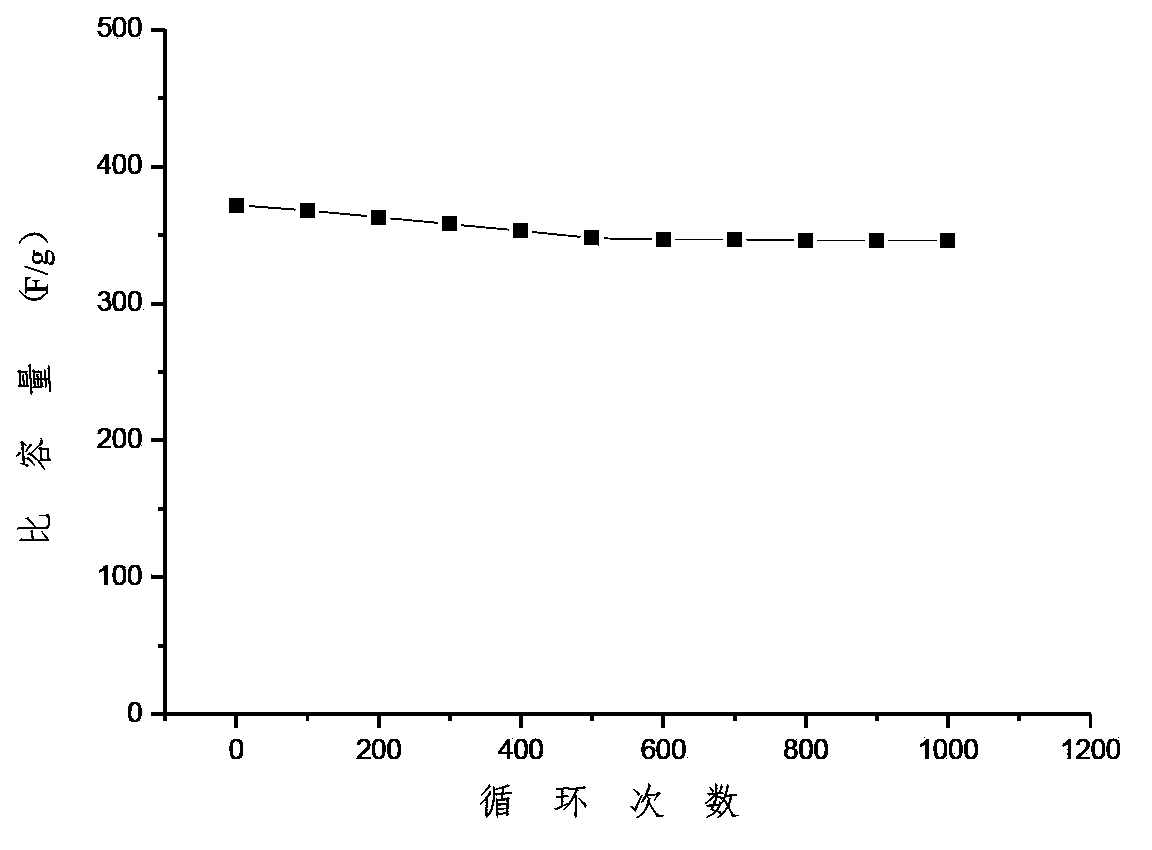

[0042] 3. Electrochemical oxidation treatment: Electrochemical oxidation is carried out using a three-electrode system. The obtained graphene electrode sheet sample is used as the working electrode, the platinum sheet is used as the auxiliary electrode, and the silver / silver chloride electrode is used as the reference electrode. The three electrodes are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com