Inverted type full inorganic nanometer oxide quantum dot light-emitting diode and manufacturing method thereof

A quantum dot light-emitting, inorganic nanotechnology, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effect of good electronic shielding function, high optical transparency, and large ionization potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

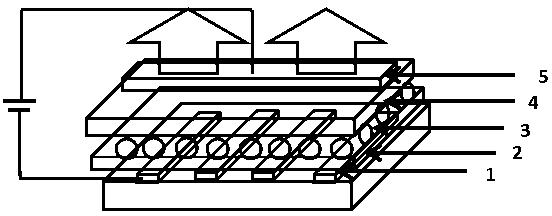

[0022] Wet preparation of trans-type all-inorganic nano-oxide quantum dot light-emitting diodes, such as figure 1 As shown, the cathode 1 is formed by plating aluminum on the glass substrate, the titanium dioxide 2 on the cathode is used as an electron transport layer, the quantum dot 3 on the titanium dioxide is used as a light-emitting layer, and nickel oxide 4 is prepared at a low temperature on the quantum dot layer , and prepare an anode 5 on the nickel oxide.

[0023] The preparation method of the quantum dot light-emitting diode device comprises the following steps:

[0024] 1) Clean the glass sheet, and prepare aluminum (also Ag, Au or Cu)) with a strip pattern (it can also be a pattern of numbers, letters, Chinese characters, etc.) on the glass sheet by thermal evaporation as the cathode, and Keep under vacuum conditions, raise the temperature to 100°C for 10 minutes and then cool down for annealing and curing;

[0025] 2) Titanium dioxide (TiO 2 ) The precursor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com