Novel nano bioceramic coated artificial ligament and preparation method of ligament

A bioceramic and artificial ligament technology, applied in coating, medical science, prosthesis, etc., can solve the problems of unsatisfactory bone healing of grafts, poor repeatability of experimental results, lack of coating thickness, etc., and achieve strong practical significance. , The parameters are easy to control, the effect of good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

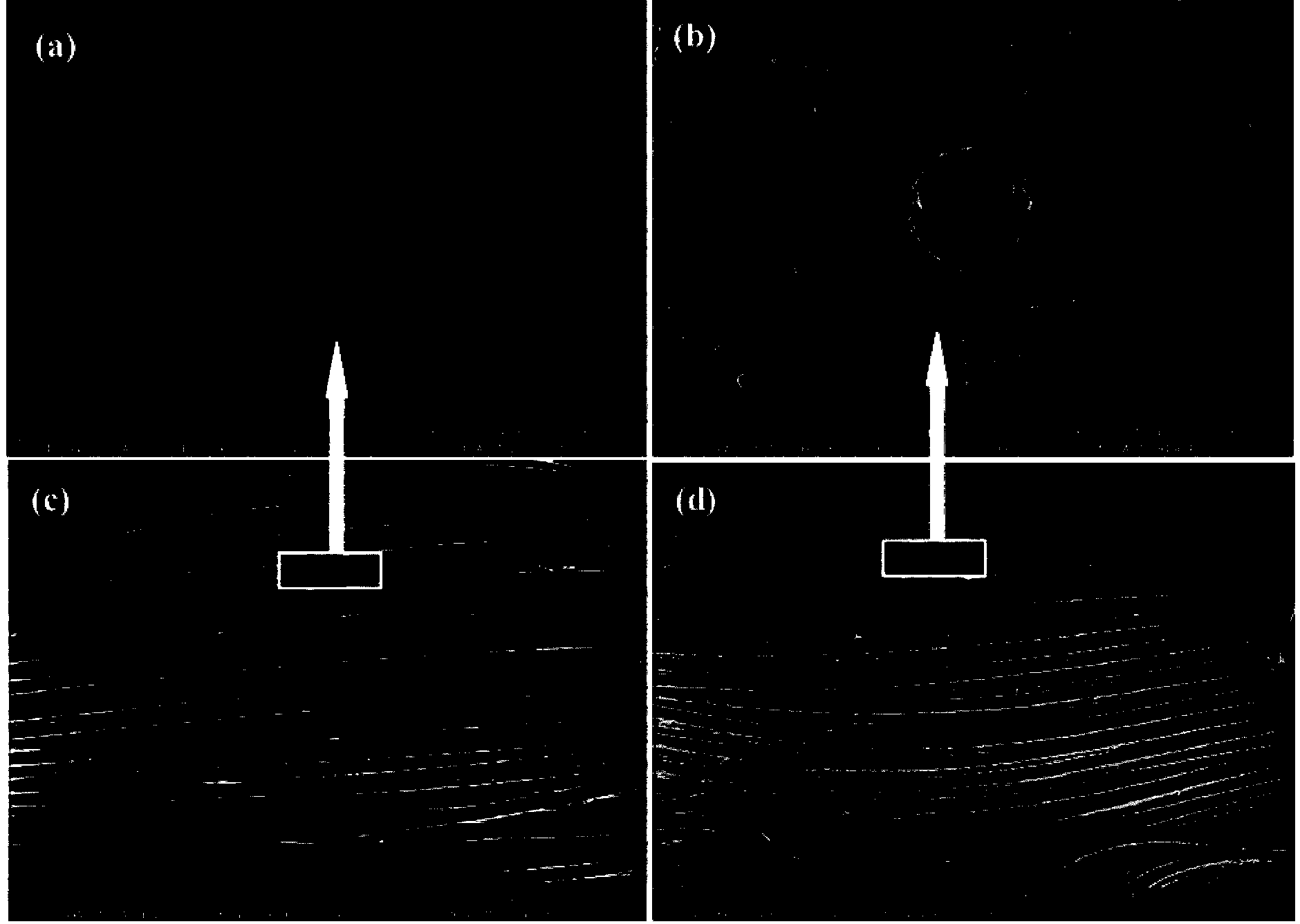

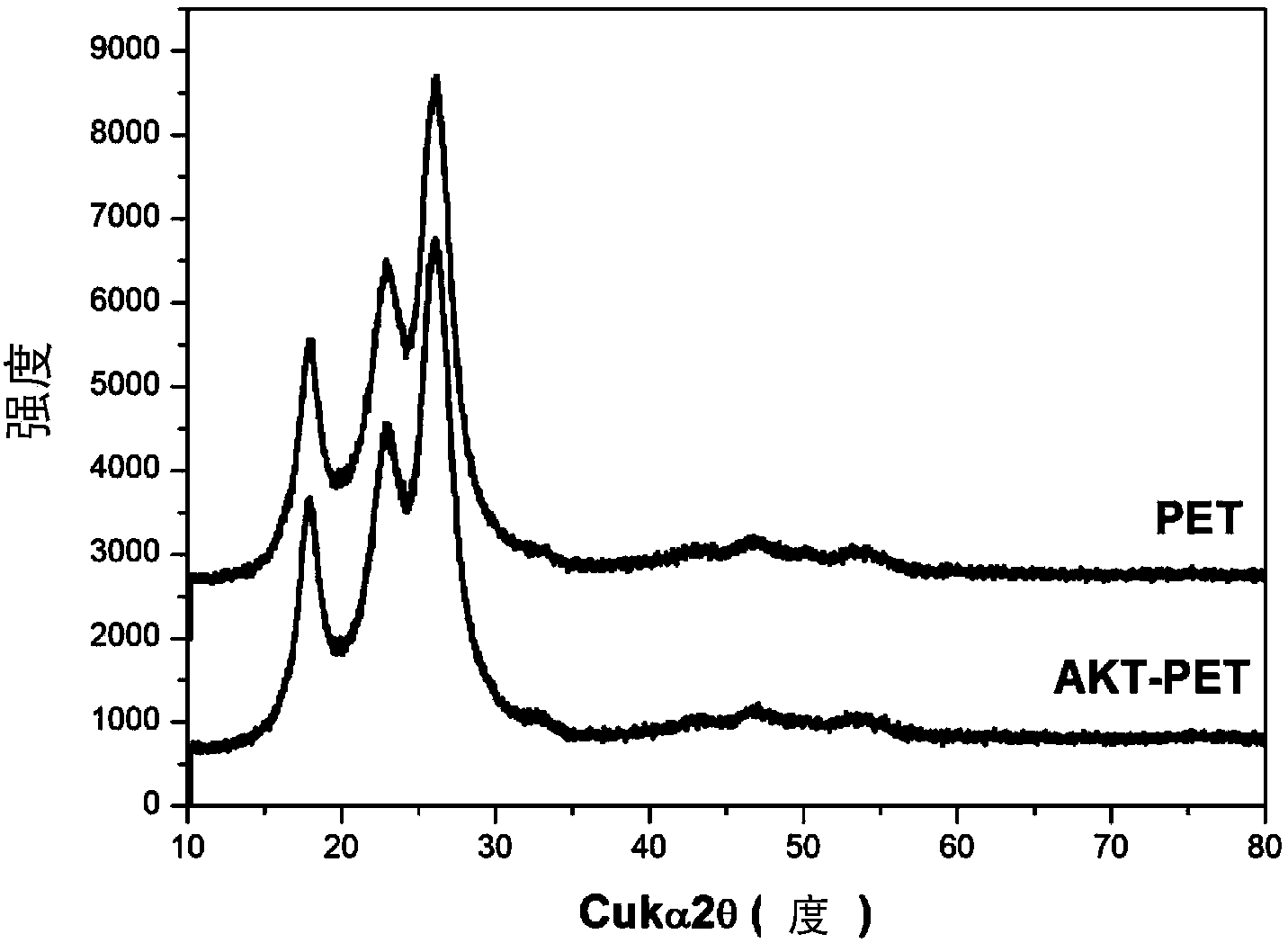

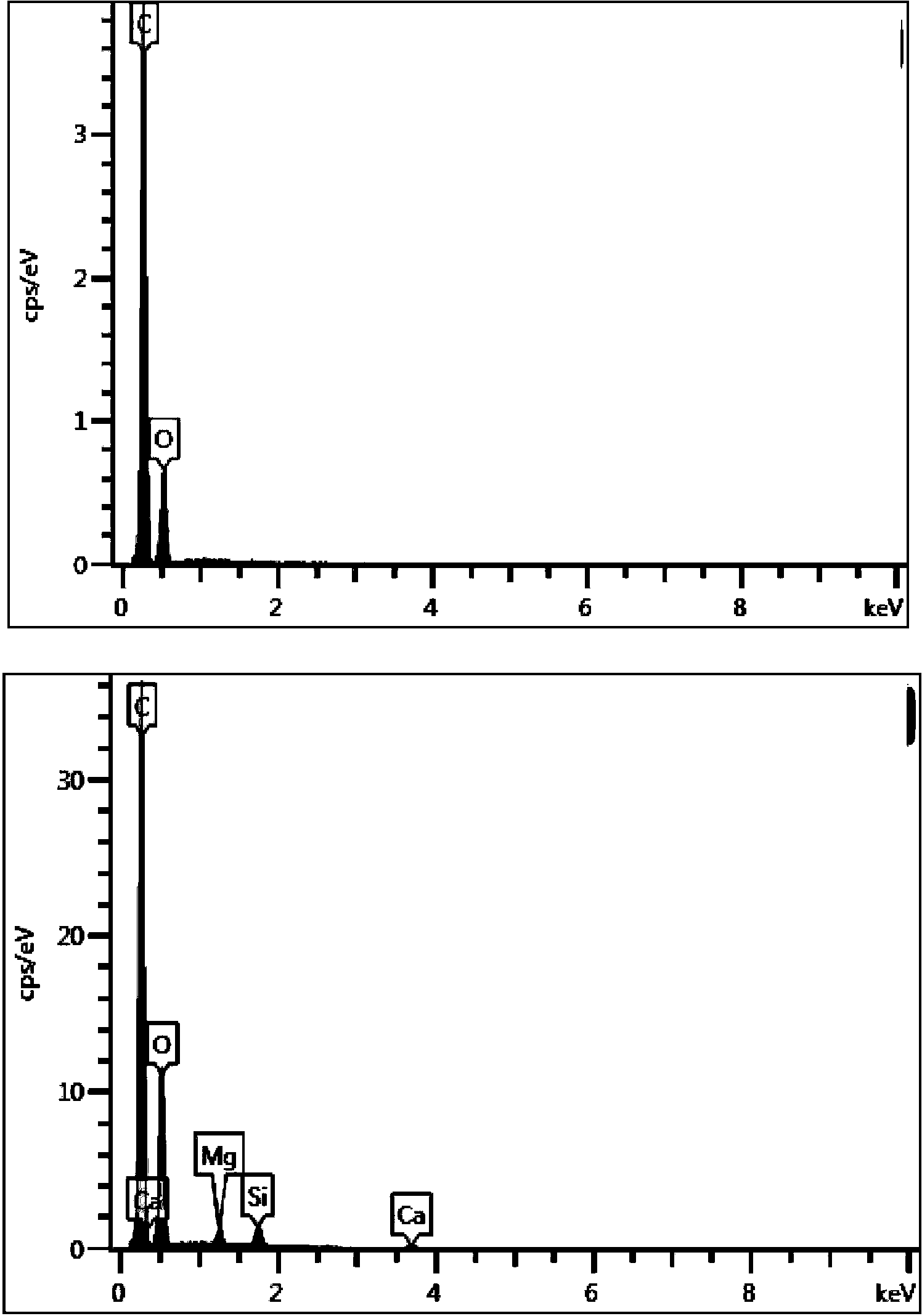

example 1

[0068] The experiment uses KrF laser (wavelength 248nm, pulse width 20ns). The laser frequency is 5 Hz, the distance between the artificial ligament and the ceramic target is 5.5 cm, and the laser beam forms an angle of 45 degrees with the target surface. In order to improve the uniformity of the deposited film and prevent the target from being broken down, the Ca-Mg-Si ceramic rotates at a speed of 2400r / hr during the deposition process, and the deposition chamber is evacuated to 20Pa by a molecular pump, and its pressure is controlled by a mechanical pump. In this experiment, the thickness, crystallinity and grain size of the coating are mainly controlled by adjusting the deposition temperature (room temperature), atmosphere pressure (20Pa), target-base distance (5.5cm) and deposition time (40 minutes). Material characterization, vascularization, osteogenesis, and graft bone healing performance studies were then performed.

example 2

[0070] The experiment uses KrF laser (wavelength 248nm, pulse width 20ns). The frequency of the laser is 6 Hz, the distance between the artificial ligament and the ceramic target is 6 cm, and the laser beam is at an angle of 30 degrees to the surface of the target. In order to improve the uniformity of the deposited film and prevent the target from being broken down, the Ca-Mg-Si ceramic rotates at a speed of 2400r / hr during the deposition process, and the deposition chamber is evacuated to 20Pa by a molecular pump, and its pressure is controlled by a mechanical pump. In this experiment, the thickness, crystallinity and grain size of the coating are mainly controlled by adjusting the deposition temperature (room temperature), atmosphere pressure (20Pa), target-base distance (6cm) and deposition time (10 minutes).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com