Preparation method of wood/nano titanium dioxide composite material

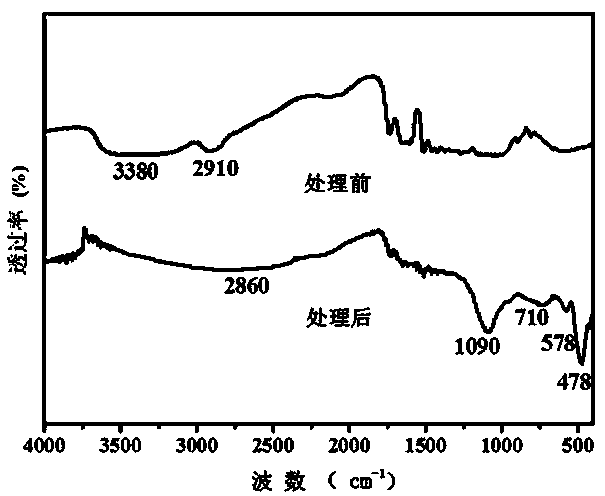

A technology of nano-titanium dioxide and composite materials, which is applied in the field of preparation of wood/nano-titanium dioxide composite materials, can solve the problems of environmental pollution, limited improvement of wood thermal stability and dimensional stability, and achieve improved hygroscopicity and antibacterial properties. The effect of low and high humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of wood / nano titanium dioxide composite material is realized through the following steps:

[0024] 1. Prepare titanium sol by hydrolyzing the precursor solution: Slowly add deionized water to the titanium salt alcohol solution to obtain a mixed solution, and add anhydrous acetic acid as a catalyst, wherein the molar ratio of deionized water to titanium salt is 1:1, The molar ratio of anhydrous alcohol solvent to titanium salt is 6:1, the molar ratio of catalyst to titanium salt is 0.1:1, add concentrated hydrochloric acid to adjust the pH value to 1.5, and stir for 30 minutes to obtain a titanium sol solution;

[0025] 2. Vacuum pressure impregnation of wood: Keep fir wood (20×20×5mm) with a moisture content of 0% at a vacuum degree of -0.08Mpa for 20 minutes, and then inject the titanium sol precursor solution under vacuum. Then pressurize under the pressure of 1Mpa for 30min, and return to the normal pressure to obtain impregnated wet wood;

[...

Embodiment 2

[0029] The preparation method of wood / nano titanium dioxide composite material is realized through the following steps:

[0030] 1. Prepare titanium sol by hydrolyzing the precursor solution: Slowly add deionized water to the titanium salt alcohol solution to obtain a mixed solution, and add anhydrous acetic acid as a catalyst, wherein the molar ratio of deionized water to titanium salt is 1:1, The molar ratio of anhydrous alcohol solvent to titanium salt is 8:1, the molar ratio of catalyst to titanium salt is 0.1:1, add concentrated hydrochloric acid to adjust the pH value to 1.5, and stir for 30 minutes to obtain a titanium sol solution;

[0031] 2. Ultrasonic vibration impregnation of wood: immerse fir (20×20×5mm) with a moisture content of 0% into the titanium sol precursor solution, and put it into an ultrasonic oscillator (frequency 80kHz, power 50W) , keep the temperature around room temperature, and obtain impregnated wet wood after ultrasonic vibration for 2 h;

[00...

Embodiment 3

[0034] The preparation method of wood / nano titanium dioxide composite material is realized through the following steps:

[0035] 1. Prepare titanium sol by hydrolyzing the precursor solution: Slowly add deionized water to the titanium salt alcohol solution to obtain a mixed solution, and add anhydrous acetic acid as a catalyst, wherein the molar ratio of deionized water to titanium salt is 1:1, The molar ratio of anhydrous alcohol solvent to titanium salt is 6:1, the molar ratio of catalyst to titanium salt is 0.1:1, add concentrated nitric acid to adjust the pH value to 1.5, and stir for 30 minutes to obtain a titanium sol solution;

[0036] 2. Ultrasonic vibration impregnation of wood: immerse fir (20×20×5mm) with a moisture content of 0% into the titanium sol precursor solution, and put it into an ultrasonic oscillator (frequency 80kHz, power 100W) , keeping the temperature at room temperature, ultrasonically oscillating for 4 hours to obtain impregnated wet wood;

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com