Preparation method of ZSM-5 molecular sieve

A technology of ZSM-5 and ZSM-11, applied in the field of preparation of ZSM-5, can solve the problems of long reaction time, loss of structure-oriented effect of template agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare the following two mixtures under stirring conditions:

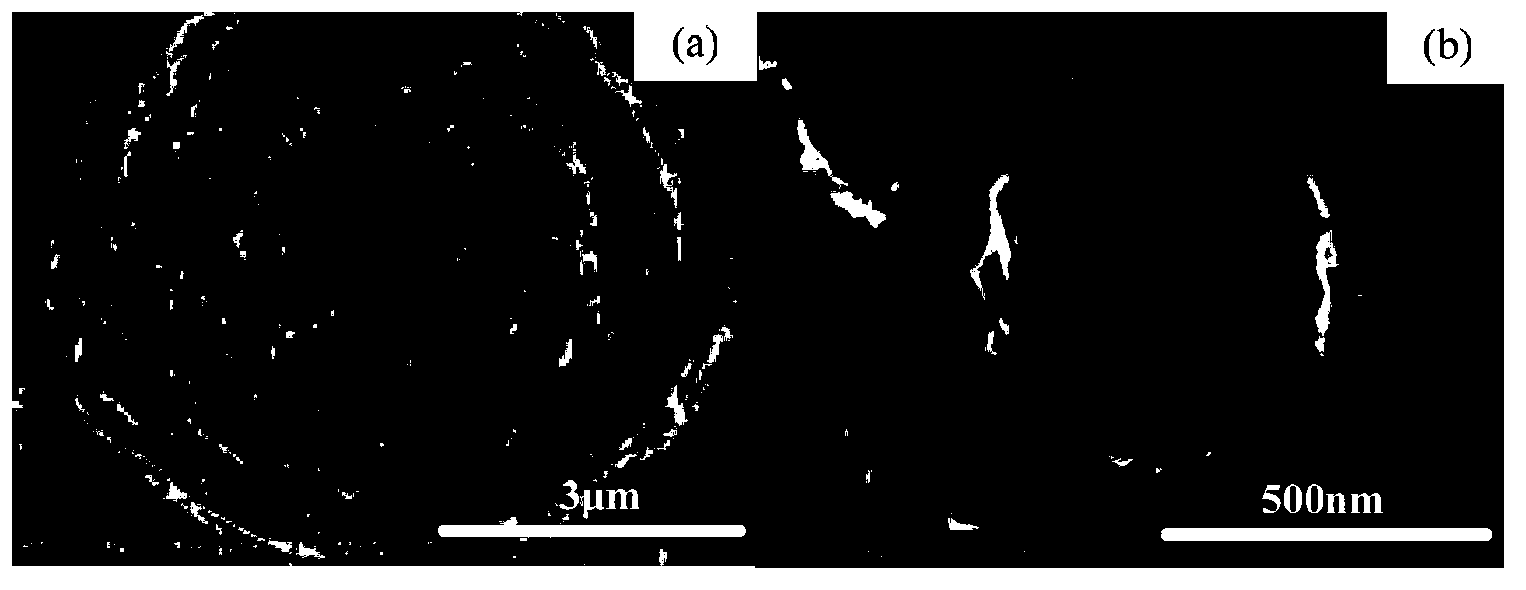

[0038] Mixture I: 19.8g silica sol (40%SiO 2 , 60%H 2 O, the same below), 20g of deionized water were added to the beaker and mixed evenly; then 0.52g (accounting for 5% of the total mass of the raw material silicon aluminum oxide) of hierarchical porous nanorods with a grain size of about 7 μm were added to plug ZSM-11 Molecular sieve powder as seed crystal ( figure 1 a), stir vigorously for 0.5h;

[0039] Mixture II: a homogeneous solution prepared with 1.17g of aluminum sulfate, 1.32g of sodium hydroxide and 15g of deionized water;

[0040] Under the condition of constant stirring, slowly add the mixture II to the mixture I, continue stirring until homogeneous. The resulting reaction mixture has a mass ratio of Na 2 O: Al 2 o 3 :SiO2 2 :H 2O=9.0:1.0:75:1500, transfer the obtained initial gel to a reaction kettle with a polytetrafluoroethylene liner, seal it and let it age at room temperature for...

Embodiment 2

[0043] Under stirring conditions, prepare the following two working solutions respectively:

[0044] Mixture I: Add 11.73g silica sol and 25g deionized into a beaker and mix well. Then add 0.26g (accounting for 5% of the total mass of the raw material silicon-aluminum oxide) hierarchically porous nanorods with a grain size of about 7 μm plugged with ZSM-11 molecular sieve powder as a seed crystal, and stir vigorously for 0.5h;

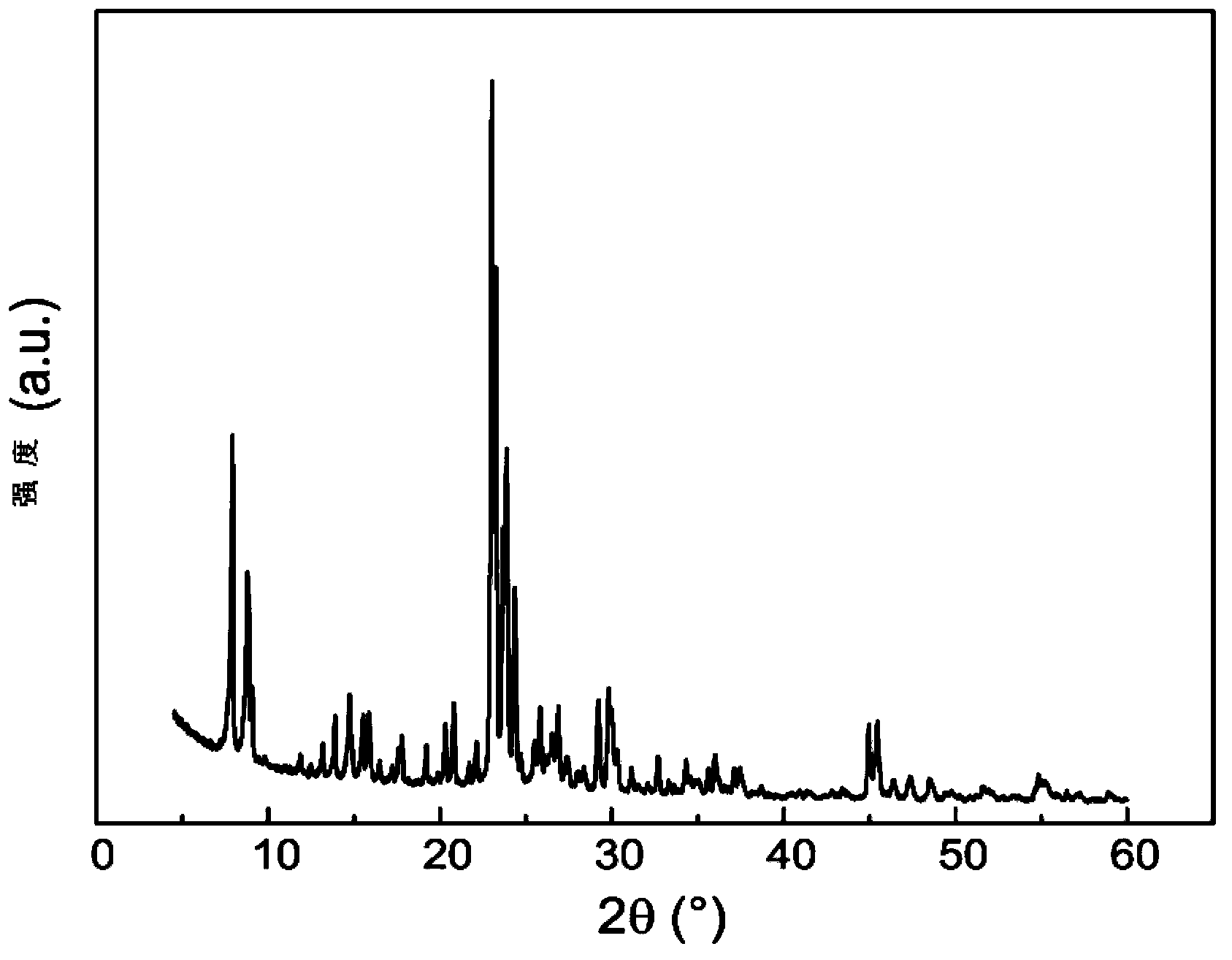

[0045] Mixture II: a homogeneous solution prepared by 0.26g aluminum sulfate, 0.34g sodium hydroxide and 10g deionized water

[0046] Under continuous stirring, slowly add solution II to solution I, and continue stirring until uniform. The molar ratio of the initial gel is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=10.6:1.0:200:6000. After sealing, it was aged at room temperature for 48 hours, and then placed in an oven for static crystallization at 170°C for 6 hours. The obtained product is ZSM-5 molecular sieve with a crystallinity of 108.76%, a hexagon...

Embodiment 3

[0048] Under stirring conditions, prepare the following two working solutions respectively:

[0049] Solution I: Add 15.00g of silica sol and 20g of deionized solution into a beaker and mix well. Then add 0.55g (accounting for 5% of the total mass of the raw material silicon-aluminum oxide) of hierarchically porous nanorods with a grain size of about 7 μm plugged with ZSM-11 molecular sieve powder as a seed crystal, and stir vigorously for 0.5h;

[0050] Solution II: a homogeneous solution prepared by 1.90g aluminum sulfate, 3.14g sodium hydroxide and 15g deionized water

[0051] Under continuous stirring, slowly add solution II to solution I, and continue stirring until uniform. The molar ratio of the initial gel is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=13.2:1.0:35:875. After sealing, it was aged at room temperature for 48 hours, and then placed in an oven for static crystallization at 170°C for 24 hours. The obtained product is ZSM-5 molecular sieve with a crystallinity of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com