Ultrasonic magnetoelectric flocculation suspension filtration purification process for oily sewage

A suspension filtration and suspension sludge filtration technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Reduce the bead size and other problems, achieve the effect of reducing scaling and passivation, enhancing the effect of electrocoagulation, and inhibiting electrode passivation

Active Publication Date: 2015-08-26

北京碧海能源装备有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to ensure that the sewage treatment can meet the standard, a large amount of high-efficiency demulsification flocculants, water purifiers, scale inhibitors, corrosion inhibitors and bactericides need to be added during the treatment process, resulting in high operating costs, increased sludge generation, emulsified There are also problems such as increased oil, and there are certain pollution and harm to the environment and human body

[0003] With the development of tertiary oil recovery technology, the following problems have been found in the use of these existing treatment processes: the particle size of oil droplets in sewage is significantly reduced due to three-element flooding oil recovery, and the existence of surfactants intensifies the degree of oil-water emulsification, making The sedimentation system that relies on gravity to separate oil and water has poor treatment effect, resulting in a greatly reduced oil removal efficiency; the three-element flooding oil recovery technology increases the polymer content in the sewage, increases the viscosity of the water body, and increases the binding force between the oil and the filter material. For the shell filter material, its relative density is further reduced, which will easily lead to excessive expansion of the backwash filter material, serious problems of pressure holding and material run-off, and for heavy filter material, a layer of gelatinous compaction is easy to form on the surface of the filter material during the filtration process The layer is not easy to break, resulting in a decrease in the backwashing effect, and it is difficult to achieve complete regeneration of the filter material; the dosage of chemicals is large, and the operating cost is high

The technical solution also involves the high-efficiency dissolved air flotation device and membrane-integrated sewage treatment equipment to realize the process, but there is a problem of membrane fouling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0090] Oily sewage with 300mg / l of oil, 250mg / l of suspended matter, 5000mg / l of salinity, 15 tons / hour, pH value of 8, voltage of 30V, current of 20A, magnetic field strength of 0.2T, ultrasonic power of 100W, frequency of 50kHz, air-water The ratio is 10, the suspension filtration time is 0.5 hours, the average oil content is less than 5mg / l, and the suspended matter is less than 3mg / l after being treated by this process.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

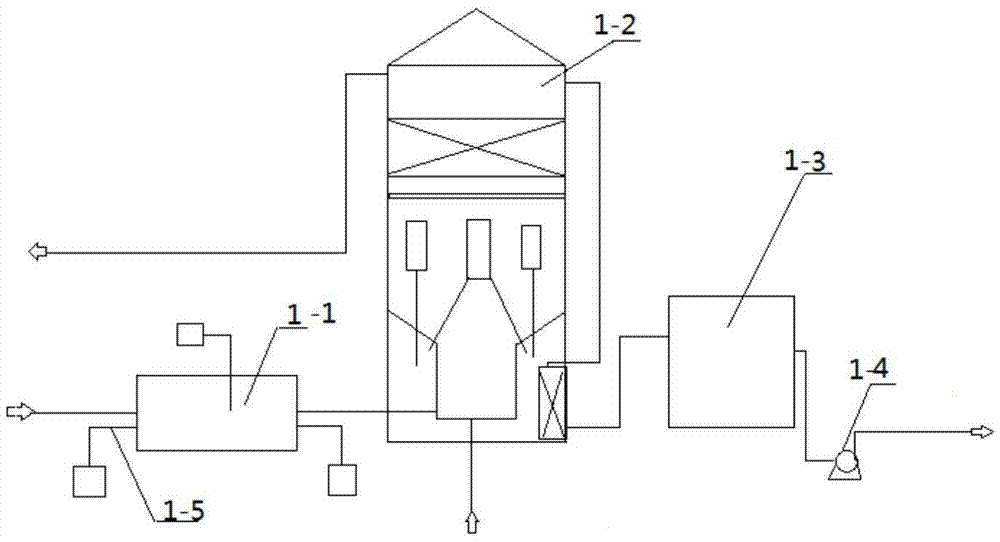

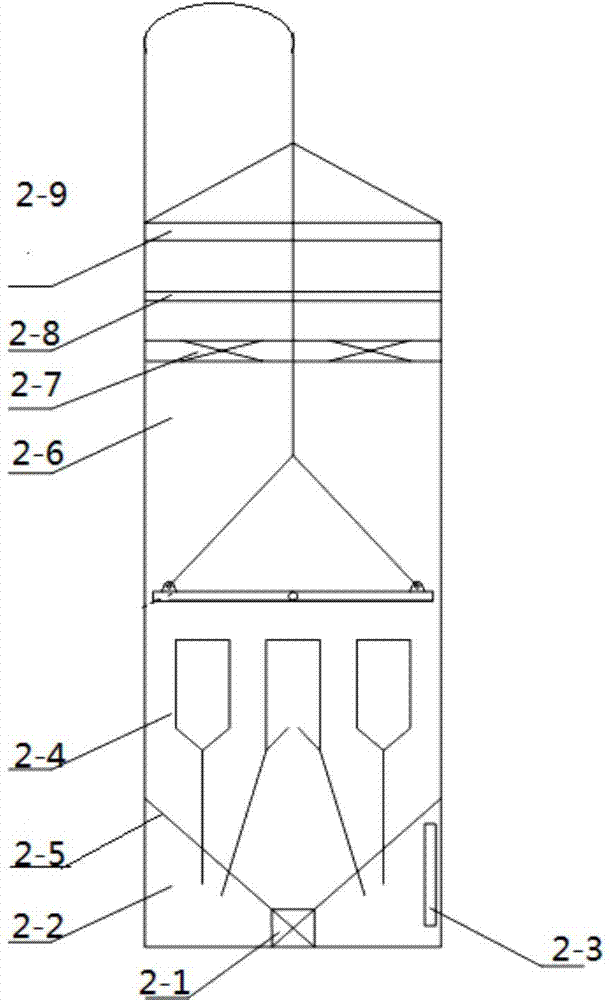

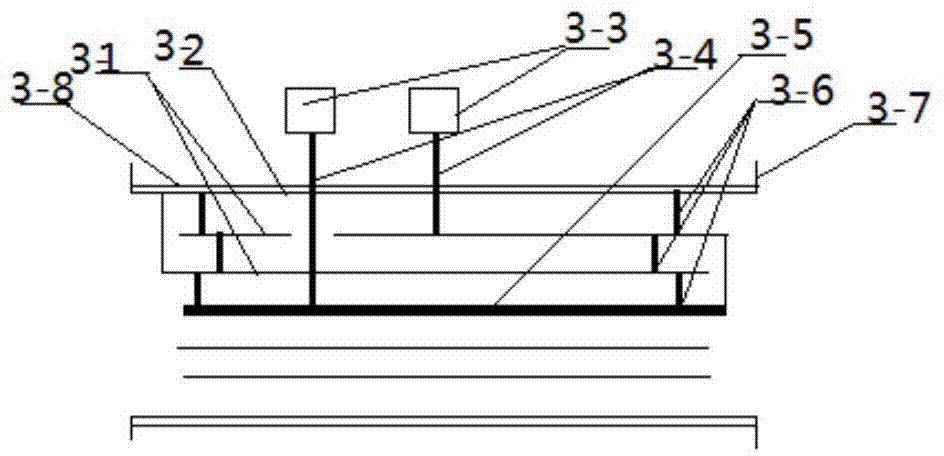

The invention relates to an oily sewage ultrasonic magneto-electric flocculation suspension filtering purifying process, and is an oily sewage medication-free purifying treatment process in combination of ultrasonic, a tubular magneto-electric flocculator and an air flotation suspended sludge filtering. The flocculation treatment is firstly performed on the oily sewage through the tubular magneto-electric flocculator, the ultrasonic device is acted on the magneto-electric flocculator, and then then treated oily sewage enters the suspended sludge filtering device, the purified water is extracted by using a lifting pump through a buffer tank. The ultrasonic, the magnetic treatment, the electric flocculation, the sterilization, the air flotation and the suspended sludge filtering are combined to prevent the electrode from scaling and passivating and prevent the device from scaling, the process is fast in filter layer formation, strong in adaptability, flexible and stable in operation, free from chemical agent in whole process, and suitable for various suspension-containing sewage treatment, and especially suitable for the oily sewage treatment.

Description

technical field [0001] The invention relates to an oily sewage treatment process, in particular to an ultrasonic magnetoelectric flocculation suspension filtration purification process for oily sewage. Background technique [0002] The treatment methods for oily sewage are mixed by physical and chemical methods. The relatively complete physical purification process includes at least oil-water separation and filtration. The oil-water separation device adopts natural sedimentation combined degreasing equipment, and the filter device uses walnut shell, quartz sand and glauconite filters. In order to ensure that the sewage treatment can meet the standard, a large amount of high-efficiency demulsification flocculants, water purifiers, scale inhibitors, corrosion inhibitors and bactericides need to be added during the treatment process, resulting in high operating costs, increased sludge generation, emulsified Oil increase and other problems also have certain pollution and damage...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/12C02F1/463C02F1/40

Inventor 娄世松沈懿桐邸建军胡传芬

Owner 北京碧海能源装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com