Sludge drying and burning device with low NOx discharge and drying and burning method

A technology of sludge drying and combustion device, applied in the field of sludge drying with low NOX emission, can solve the problems of high volatile content of dry ash-free base, large emission of greenhouse gas and high moisture content of sludge, so as to reduce the Emissions, suppression of NOX generation, and effects of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

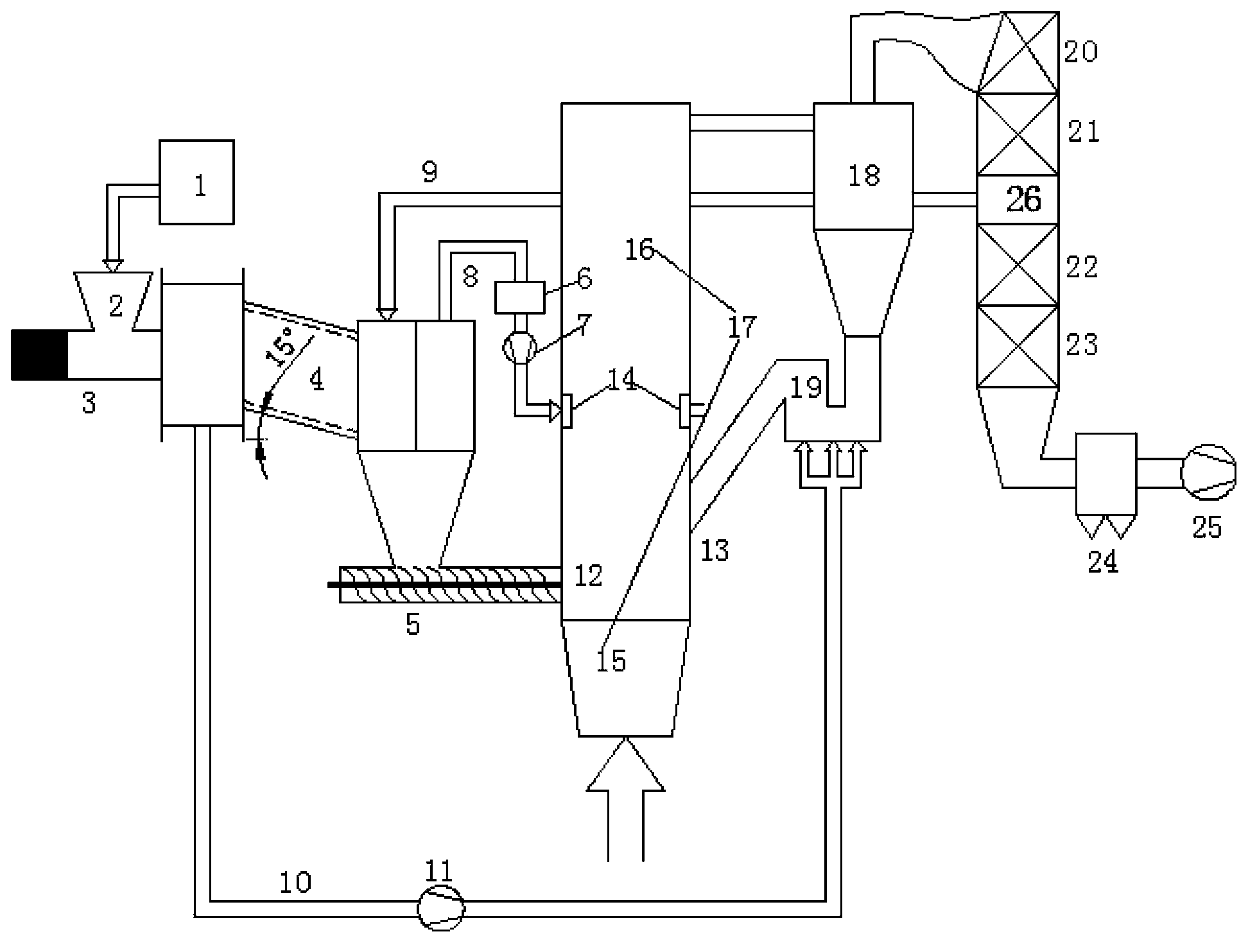

[0027] figure 1 It is a structural schematic diagram of the sludge combustion device of the present invention. As shown, a low NO X Discharged sludge drying and burning plants, including sludge drying plants and sludge burning plants:

[0028] The sludge drying device includes a silo 1, a hopper 2, a piston feeder 3, a rotary drying furnace 4, a screw feeder 5, a chiller 6, a fan 7, a sludge drying pyrolysis gas pipeline 8, The first flue gas circulation pipe 9, the second flue gas circulation pipe 10 and the circulation fan 11;

[0029] The sludge combustion boiler includes a boiler furnace 17 divided into a dense phase zone 15 and a dilute phase zone 16, a sludge feed port 12, a feed return port 13, a sludge drying pyrolysis gas nozzle 14, a cyclone separator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com