Preparation method of starch zeolite molecular sieve flocculating agent

A technology of zeolite molecular sieve and flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of excellent performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

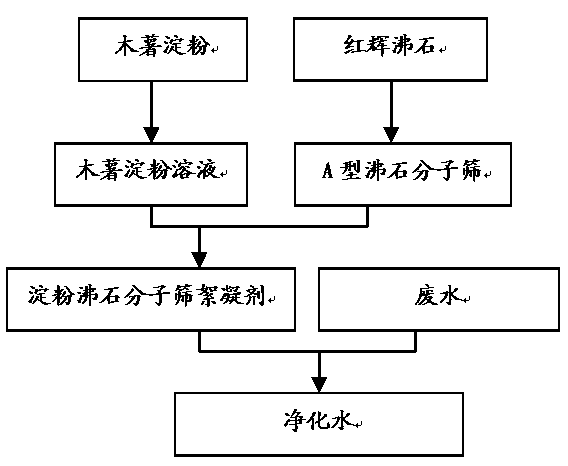

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 2.0 grams of tapioca starch into a 500mL beaker, add distilled water and stir to make a paste, then add boiling water while stirring, and finally heat to boiling, after cooling, centrifuge at 4500 rpm for 10 minutes, and take the supernatant solution to obtain tapioca starch solution.

[0025] (2) Put 30.0 g of hematilite powder and 90 ml of HCl solution with a concentration of 15% by mass in a 250 ml three-neck flask, and stir it electrically for 2 hours at 90°C, filter, and wash until Cl-free - , dried into acidified zeolite.

[0026] (3) Mix 8.0 grams of NaOH and 4.0 grams of NaAlO 2 Mix and add 192 ml of water to prepare a solution, add it to a three-necked bottle, then add 4.0 g of the acidified zeolite obtained in step (2), stir magnetically, and crystallize at a temperature of 90°C and for a crystallization time of 6 hours. The product is filtered, washed, After drying, A-type zeolite molecular sieves (Na 2 O·Al 2 o 3 2SiO2 2 4.5H 2 O).

[0027]...

Embodiment 2

[0033] (1) Weigh 5.0 grams of tapioca starch into a 500mL beaker, add distilled water and stir to make a paste, then add boiling water while stirring, and finally heat to boiling, after cooling, centrifuge at 4500 rpm for 10 minutes, and take the supernatant solution to obtain tapioca starch solution.

[0034] (2) Put 40.0 g of hematilite powder and 120 ml of HCl solution with a concentration of 15% by mass in a 250 mL three-necked flask, and stir it electrically for 1 hour at 80°C, filter, and wash until there is no Cl - , dried into acidified zeolite.

[0035] (3) Mix 10.0 g NaOH and 5.0 g NaAlO 2 Mix and add 240 ml of water to prepare a solution, add it to a three-necked bottle, then add 5.0 g of the acidified zeolite obtained in step (2), stir magnetically, and crystallize at a temperature of 100°C and a crystallization time of 7 hours. The product is filtered, washed, After drying, A-type zeolite molecular sieves (Na 2 O·Al 2 o 3 2SiO2 2 4.5H 2 O).

[0036] (4) Ta...

Embodiment 3

[0038] (1) Weigh 2.0 grams of tapioca starch into a 500mL beaker, add distilled water and stir to make a paste, then add boiling water while stirring, and finally heat to boiling, after cooling, centrifuge at 4500 rpm for 10 minutes, and take the supernatant solution to obtain tapioca starch solution.

[0039] (2) Put 30.0 g of hematilite powder and 90 ml of HCl solution with a concentration of 15% by mass in a 250 ml three-neck flask, and stir it electrically for 2 hours at 90°C, filter, and wash until Cl-free - , dried into acidified zeolite.

[0040] (3) Mix 8.0 grams of NaOH and 4.0 grams of NaAlO 2 Mix and add 192 ml of water to prepare a solution, add it to a three-necked bottle, then add 4.0 g of the acidified zeolite obtained in step (2), stir magnetically, and crystallize at a temperature of 90°C and for a crystallization time of 6 hours. The product is filtered, washed, After drying, A-type zeolite molecular sieves (Na 2 O·Al 2 o 3 2SiO2 2 4.5H 2 O).

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com