Preparation method for polymer microspheres having mixed absorption mode

A technology of polymer microspheres and patterns, applied in the field of polymers, to achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of porous polystyrene resin

[0028] Prepare 1 L of an aqueous solution containing 10 g / L of polyvinyl alcohol and 20 g / L of gelatin as the aqueous phase solution of the reaction system for preparing polystyrene porous polymer microspheres by suspension polymerization. Dissolve 120mg of benzoyl peroxide in a mixed solution containing 12mL of styrene, 3mL of divinylbenzene and 18mL of n-heptane, add the oily mixed solution to 60mL of aqueous solution, and obtain a mixed system of oil-water two-phase layering Stir at room temperature with a mechanical stirring speed of 300 r.p.m. for 1 hour, then raise the temperature to 80° C., and polymerize for 20 hours. The obtained product polystyrene porous polymer microspheres are washed three times with acetone and ethanol in turn. Vacuum dry at 60°C for 12 hours before use.

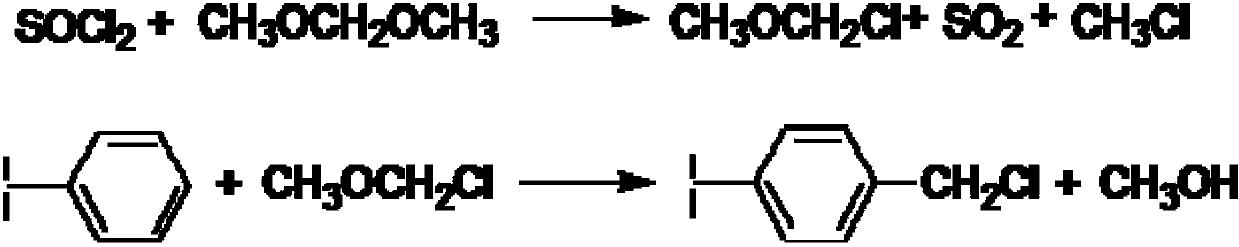

[0029] Chloromethyl resin preparation

[0030] Slowly add 40mL of thionyl chloride into 40mL of methylal, stir for 1 hour, mix the resulti...

Embodiment 2

[0035] (1) Preparation of porous polystyrene resin

[0036] Prepare 1L of aqueous solution containing polyvinyl alcohol (PVA) as 8g / L and gelatin as 14g / L as the aqueous phase solution of the polystyrene porous polymer microsphere reaction system prepared by suspension polymerization. Dissolve 120mg of benzoyl peroxide (BPO) in a mixed solution containing 12mL of styrene, 3mL of divinylbenzene and 20mL of n-heptane, add the oily mixed solution to 60mL of aqueous solution, and the resulting oil-water two-phase separation The mixed system was stirred at room temperature with a mechanical stirring speed of 300r.p.m. for 1 hour, then the temperature was raised to 80°C, and the polymerization reaction was carried out for 20 hours, and the obtained product polystyrene porous polymer microspheres were washed with acetone and ethanol in sequence After three times, vacuum-dry at 60° C. for 12 hours before use.

[0037] Chloromethyl resin preparation

[0038] Slowly add 40mL of thiony...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com