Rapidly hydrated liquid guanidine gum and fracturing base fluid containing same

A technology of fracturing base fluid and guar gum, which is applied in the field of fracturing base fluid and rapid hydration liquid guar gum, which can solve the problems of increasing the safety risk of the construction site, the number of liquid tanks, and the lack of liquid guar gum system, etc. Large-scale production, simple preparation method and high construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

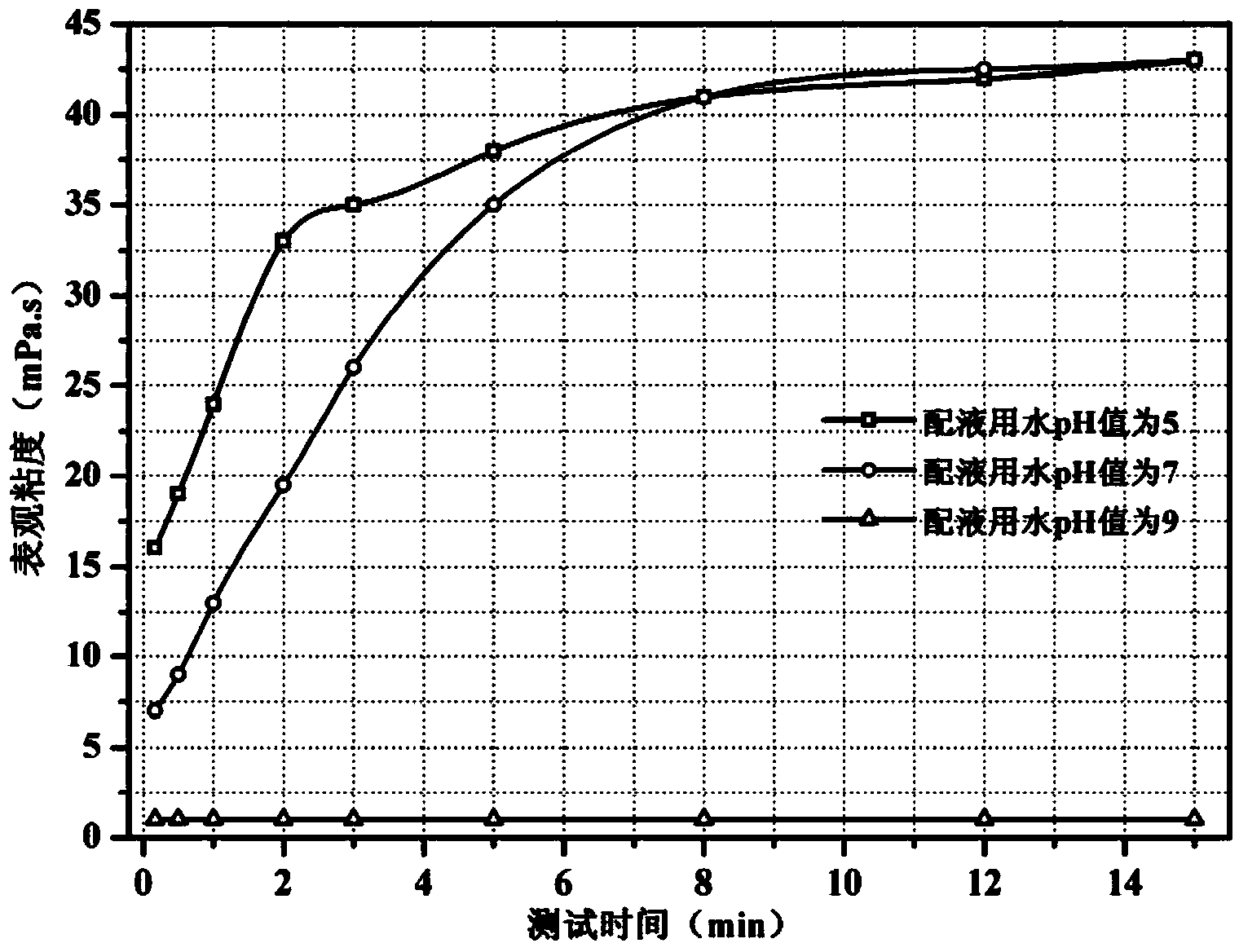

[0034] At room temperature, add 0.6% of high-substitution hydroxypropyl cellulose to polyethylene glycol (molecular weight: 300Da) containing 83.3% of the total mass fraction, stir at high speed for 10 minutes, and wait until the above mixture is uniformly dissolved Finally, add hydroxypropyl guar gum which accounts for 16% of the total mass fraction, and stir at a high speed for 15 minutes to obtain fast hydration liquid guar gum. The fracturing base fluid prepared by using the fast hydrating liquid guar gum and water with a pH value not greater than 5 at a weight ratio of 1:50 can reach 85% of the maximum viscosity within 3 minutes.

[0035] The viscosity of the prepared above-mentioned rapidly hydrating liquid guar gum was tested by a Huck RT-20 rotational rheometer, the sample size was 50ml, and the rotor was PZ36. The Rapid Hydration Liquid Guar Gum in 340S -1 The lower apparent viscosity value is 190mPa.s, and the fluidity is excellent. In addition, slowly pour the fas...

Embodiment 2

[0037] At room temperature, add 0.4% of high-degree substitution hydroxypropyl cellulose to polyethylene glycol (molecular weight: 200Da) containing 50% of the total mass fraction, stir at high speed for 10 minutes, and wait for the above mixture to dissolve evenly , add 49.6wt% carboxymethyl hydroxypropyl guar gum, and stir at high speed for 15 minutes to obtain fast hydration liquid guar gum. The fracturing base fluid prepared by using the rapidly hydrating liquid guar gum and the water with a pH value not greater than 5 at a weight ratio of 1:60 can reach 90% of the maximum viscosity within 5 minutes.

[0038] Viscosity test of the rapid hydration liquid guar gum prepared above was carried out by Hack RT-20 rotational rheometer, the sample size was 50ml, and the rotor was PZ36. The formula of Rapid Hydration Liquid Guar in 340S -1 The apparent viscosity value under is about 3450mPa.s, and basically does not flow. In addition, slowly pour the rapidly hydrating liquid guar ...

Embodiment 3

[0040]At room temperature, add 0.4% of high-substitution hydroxypropyl cellulose to the polyethylene glycol (molecular weight: 1000Da) containing 64.4% of the total mass fraction, stir at high speed for 10 minutes, and continue to add 3% nano-hydraulic acid The water-based organoclay was ultrasonically treated in an ultrasonic cleaner for 30 minutes. After the above mixture was uniformly dissolved, 32.2% carboxymethyl hydroxypropyl guar gum was added and stirred at high speed for 15 min to obtain a rapidly hydrating liquid guar gum. The fracturing base fluid prepared by using the fast hydrating liquid guar gum and water with a pH value not greater than 5 at a weight ratio of 1:100 can reach 88% of the maximum viscosity within 4 minutes.

[0041] Viscosity test of the rapid hydration liquid guar gum prepared above was carried out by Hack RT-20 rotational rheometer, the sample size was 50ml, and the rotor was PZ36. The Rapid Hydration Liquid Guar Gum in 340S -1 The apparent vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com