Refining device for silicon-manganese alloy tailings and method of using the same

A technology for silicon-manganese alloy and tailings, which is applied in the field of refining devices for silicon-manganese alloy tailings, can solve the problems of wasting Mn elements, unfavorable comprehensive utilization, etc., saves energy and resources, is easy to color and tempers, and reduces production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

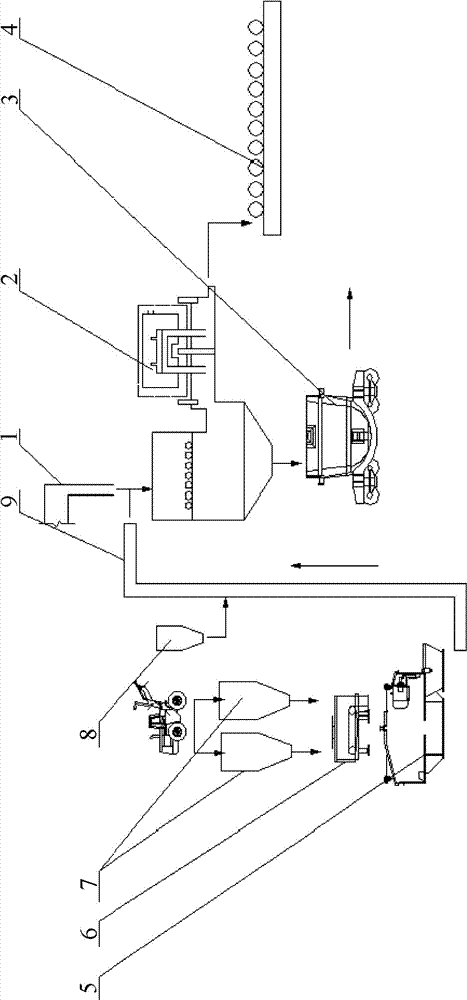

[0022] A refining device for silicon-manganese alloy tailings, comprising silicon-manganese alloy slag outlet 1, melting furnace 2, metal casting machine 3, glass-ceramic forming machine 4, mixer 5, quantitative feeder 6, auxiliary materials Bin 7, reductant storage bin 8 and hoist 9, such as figure 1 As shown, the specific structure is:

[0023] Mixer 5, quantitative feeder 6, auxiliary material bin 7, reducing agent storage bin 8 and hoist 9 are arranged on the side of silicon-manganese alloy slag outlet 1, melting furnace 2, metal casting machine 3 and microcrystalline The glass forming machine 4 is located on the other side of the silicon-manganese alloy slag outlet 1;

[0024] The discharge port of silicon-manganese alloy slag discharge port 1 is set directly above the feed port of melting furnace 2, the feed port of metal casting machine 3 is located directly below the iron tap port of melting furnace 2, and the glass ceramics The feed port of the forming machine 4 is ...

Embodiment 2

[0030] A refining device for silicon-manganese alloy tailings, comprising silicon-manganese alloy slag outlet 1, melting furnace 2, metal casting machine 3, glass-ceramic forming machine 4, mixer 5, quantitative feeder 6, auxiliary materials Bin 7, reducing agent storage bin 8 and hoist 9, the specific structure is: in the auxiliary materials stored in the auxiliary material bin 7, the quality of quartz stone is 2.2 times that of sodium carbonate; in the reducing agent stored in the reducing agent storage bin 8, The quality of ferrosilicon powder is 1.6 times that of coke. Other structures are all the same as in Embodiment 1.

[0031] When the present embodiment is in use, proceed as follows: the amount of reducing agent added is: the quality of the ferrosilicon powder in the reducing agent is 7.6% of the Mn element content in the high-temperature slag, and the amount of auxiliary materials added is 10.6% of the high-temperature slag quality. %. Other steps are all the same ...

Embodiment 3

[0033] A refining device for silicon-manganese alloy tailings, comprising silicon-manganese alloy slag outlet 1, melting furnace 2, metal casting machine 3, glass-ceramic forming machine 4, mixer 5, quantitative feeder 6, auxiliary materials Bin 7, reducing agent storage bin 8 and hoist 9, the specific structure is: in the auxiliary materials stored in the auxiliary material bin 7, the quality of quartz stone is 2.4 times that of sodium carbonate; in the reducing agent stored in the reducing agent storage bin 8, The quality of ferrosilicon powder is 2.2 times that of coke. Other structures are all the same as in Embodiment 1.

[0034] When the present embodiment is used, it is carried out in sequence as follows: the addition amount of the reducing agent is: the quality of the ferrosilicon powder in the reducing agent is 8.2% of the Mn element content in the high-temperature slag, and the addition of auxiliary materials is 16.2% of the high-temperature slag quality. %. Other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com