Installing device for aiming and positioning infrared thermometric optical probe on small furnace cover

An optical probe, infrared temperature measurement technology, used in measurement devices, optical radiation measurement, radiation pyrometry, etc. Thermal cooling, high aiming and positioning accuracy, and the effect of reducing the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

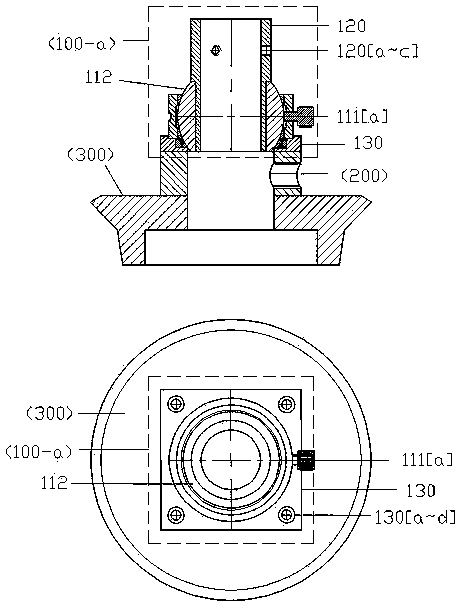

[0036] figure 1 . It is an integrated aiming and positioning installation device (100-a) that uses jacking screws to lock joint balls.

[0037] like figure 1 .shown: an integrated aiming and positioning installation device (100-a), its main body is a radial ball joint bearing (110), and the joint ball (112) is surrounded by an outer ring bearing bush (111) with an inner spherical surface In the middle, due to the sliding contact between the inner and outer spherical surfaces, the position of the center of the joint ball (112) remains unchanged, and the ball can be tilted and rotated within a certain angle range; on the outer ring bearing bush (111), there are three 120° evenly distributed The screw holes (111[a]), (111[b]) and (111[c]) are screwed into the jacking screws to lock the joint ball (112); there are upper and lower layers in the middle of the installation base (130) Annular steps (131) and (132), in the lower annular step (132), the sealing gasket (140) is embedde...

Embodiment 2

[0047] Image 6 .It is an integrated aiming and positioning installation device (100-b) that uses a lock nut (150) to lock the joint ball (112).

[0048] like Image 6 .As shown: the integrated aiming and positioning installation device (100-b) still adopts a centripetal ball joint structure; the difference is: the joint ball (112) is enclosed in the bearing ball seat (133), ball cap ( 140) and the elastic sealing ring (180); on the upper layer of the ball cap (140), there are single-layer wave compression springs (160) and lock nuts (150); the inner thread of the lock nut (150) and the bearing ball seat ( 133) on the external thread screw connection; the position of the ball center of the joint ball (112) remains unchanged, and can be tilted and rotated within a certain angle range; twist the lock nut (150), and press down on the single-layer wave compression spring ( 160) and ball cap (140), which can lock the joint ball (112); the elastic sealing ring (180) is made of hig...

Embodiment 3

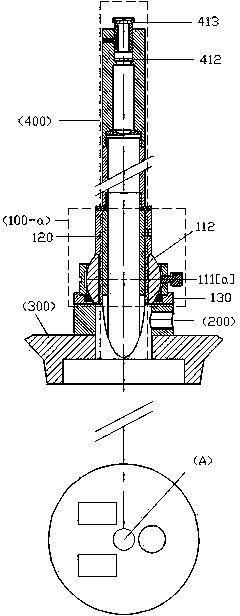

[0050] Figure 7 . It is also an integrated aiming and positioning installation device (100-c) that uses a lock nut (150) to lock the joint ball (112).

[0051] like Figure 7 . Shown: Embodiment 3. The difference from Embodiment 2 is: the bearing ball seat (133) and the air blower (200) of the integrated aiming and positioning installation device (100-c) are connected as one Yes, the thread (201) at the lower end of the air purger (200) is tightened and installed in the inner screw hole (301) in the center of the small furnace cover (300); the rest of the embodiment 3 is the same as that of the embodiment 2. Tired.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com