Dental pit and fissure sealant

A technology of pit and fissure sealing and dentistry, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of high price, high foreign exchange consumption, and product dependence on imports, and achieve high cross-linking degree, less heat release, and accelerated polymerization and the effect of the curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

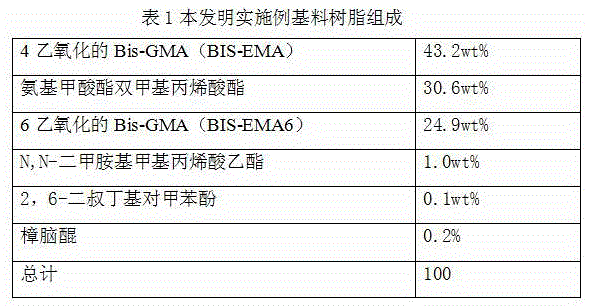

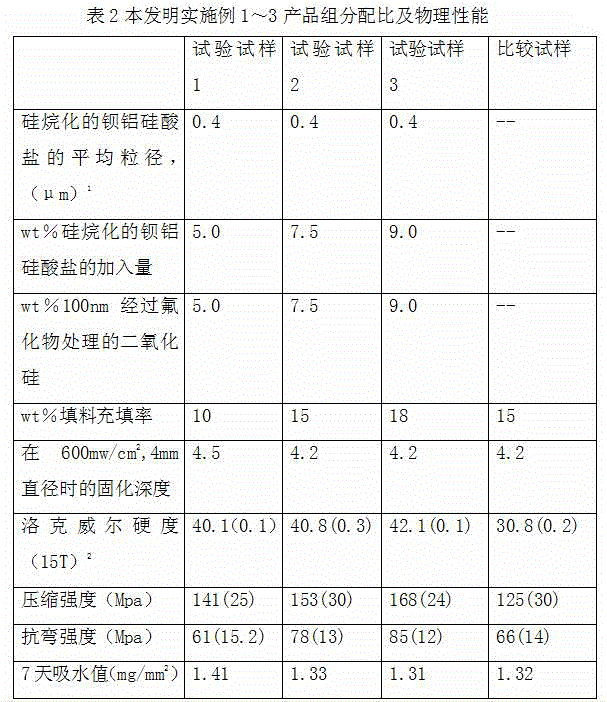

[0038] The composition of the base resin (ie, the polymerizable acrylic resin containing the photoinitiating system) of Examples 1-3 of the present invention is shown in Table 1. The distribution ratio of the product components of Examples 1-3 and their physical properties are recorded in Table 2.

[0039] preparation:

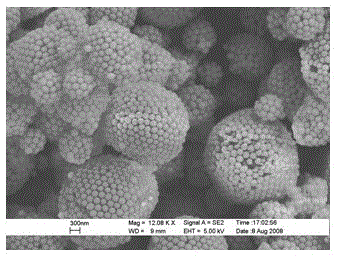

[0040] (1) Preparation of filler submicron silica powder: put 100ml of 17.15mol / L absolute ethanol solution and 27ml of 25% ammonia solution into a 1L glass reactor, stir mechanically for 1.5 to 2.5 hours; add 0.5g of PEG1000 Dissolve in 56ml of deionized water, add the aqueous solution of this dispersant to the reactor, stir at high speed to make the solution evenly mixed, slowly add 90ml, 4.48mol / L Si (OC 2 h 5 ) 4 , high-speed stirring and reacting for 40 minutes to obtain a uniform and stable sol; the sol was spray-dried, the inlet temperature of the spray dryer was 175-185°C, and the outlet temperature was 85-95°C to obtain spherical carbon dioxide wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com