Nano-liposome emulsion and preparation method thereof

A nano-liposome and emulsion technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve problems such as reducing the sensitization effect of seaweed extracts, and achieve enhancement and extension of beauty repair, promotion of growth and improvement. Repair and reduce allergic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

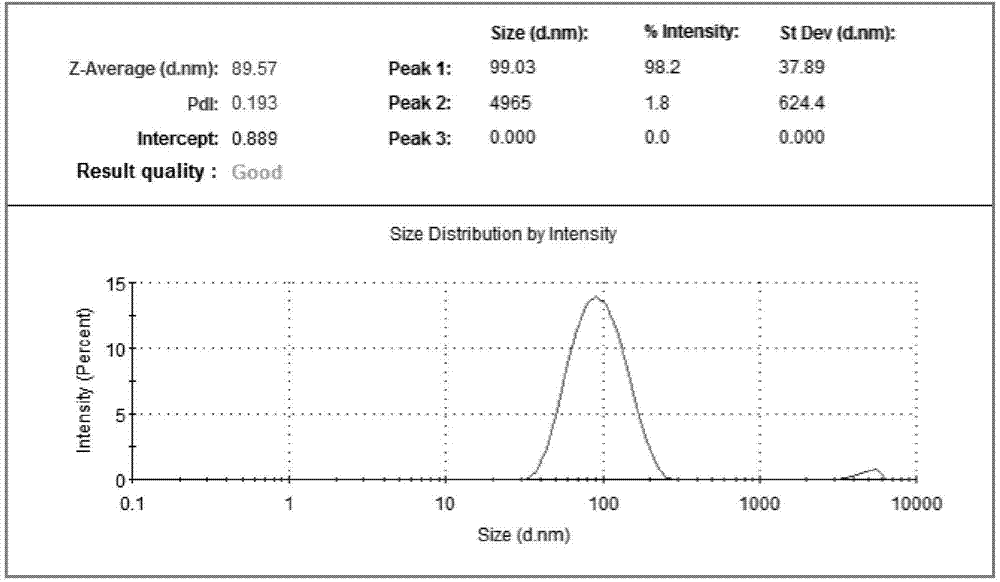

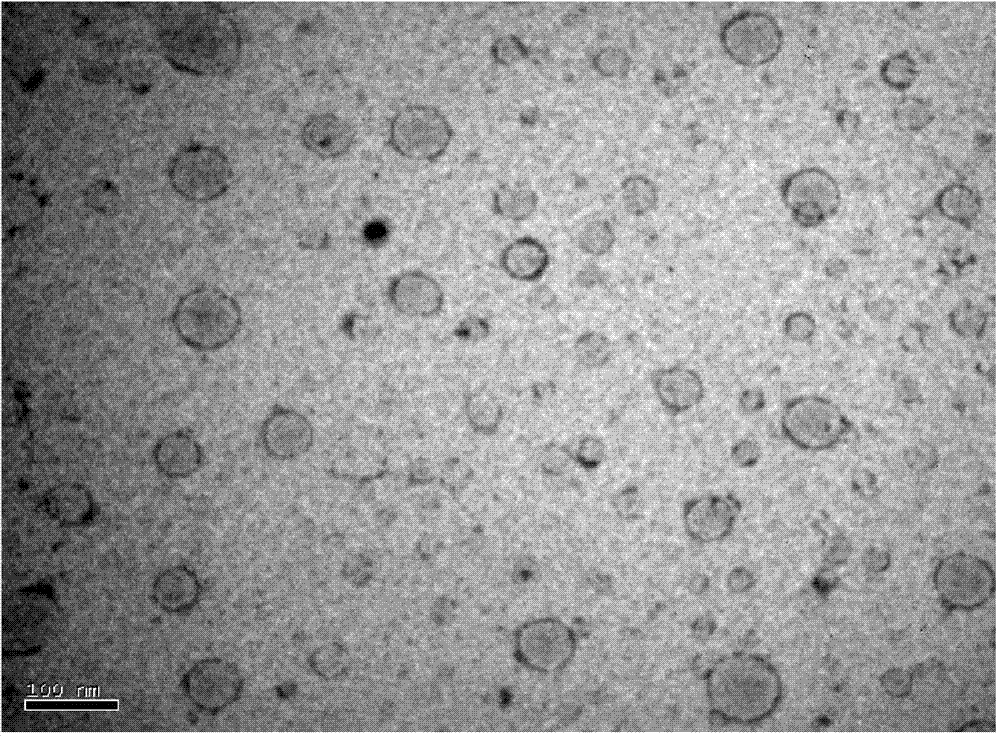

Image

Examples

Embodiment 1

[0030] 1. Weigh 20.0g of seaweed extract, 10.0g of soybean lecithin, 1.0g of cholesterol and 0.01g of vitamin E for cooling and ultrasonic solubilization, add 10.0g of Tween 80, heat up to 55-60°C, and fully stir until uniform Oil phase, keep warm for 10min.

[0031] 2. Weigh 15.0g of glycerin, add it to 44.0g of pure water, raise the temperature to 55-60°C, stir evenly to form the water phase, and keep it warm for 10min.

[0032] 3. Pump the oil phase material into the water phase for premixing, adjust the rotation speed to 10000r / min for high-speed homogenization for 20 minutes, and keep warm at 55-60°C for 10 minutes to make the primary emulsion.

[0033] 4. Move the primary emulsion to a high-pressure homogenizer, and carry out high-pressure homogenization circulation treatment under a pressure of 80 MPa. Take out the emulsion when it becomes transparent or translucent, and cool it down to room temperature naturally to obtain the skin repair function nano liposome emulsio...

Embodiment 2

[0035] 1. Weigh 10.0g of seaweed extract, 15.0g of soybean lecithin, 2.0g of cholesterol and 0.1g of vitamin E to cool and sonicate, add 10.0g of Tween 80, heat up to 55-60°C, and fully stir until uniform Oil phase, keep warm for 10min.

[0036] 2. Weigh 20.0g of glycerin, add it to 42.9g of pure water, raise the temperature to 55-60°C, stir evenly to form the water phase, and keep it warm for 10min.

[0037] 3. Pump the oil phase material into the water phase for premixing, adjust the rotation speed to 10000r / min for high-speed homogenization for 20 minutes, and keep warm at 55-60°C for 10 minutes to make the primary emulsion.

[0038] 4. Move the primary emulsion to a high-pressure homogenizer, and carry out high-pressure homogenization circulation treatment under a pressure of 100 MPa. Take out the emulsion when it becomes transparent or translucent, and cool it down to room temperature naturally to obtain the skin repair function nano liposome emulsion coated with seaweed...

Embodiment 3

[0040] 1. Weigh 15.0g of seaweed extract, 20.0g of egg yolk lecithin, 3.0g of stigmasterol and 0.05g of vitamin C for cooling and ultrasonic dissolution, add 20.0g of polyethylene glycol 4000, heat up to 55-60°C, and stir thoroughly Until the oil phase is uniform, keep warm for 10 minutes.

[0041] 2. Weigh 10.0g of propylene glycol, add it to 32.0g of pure water, raise the temperature to 55-60°C, stir evenly to form the water phase, and keep it warm for 10min.

[0042] 3. Pump the oil phase material into the water phase for premixing, adjust the rotation speed to 10000r / min for high-speed homogenization for 20 minutes, and keep warm at 55-60°C for 10 minutes to make the primary emulsion.

[0043] 4. Move the primary emulsion to a high-pressure homogenizer, and carry out high-pressure homogenization circulation treatment under a pressure of 120MPa. Take out the emulsion when it becomes transparent or translucent, and cool it down to room temperature naturally to obtain the sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com