Flue gas pollutant control integrated purification process

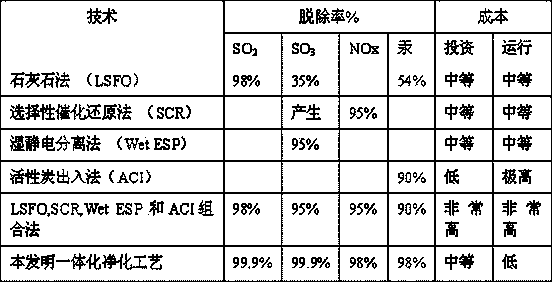

A purification process and pollutant technology, which is applied in the direction of air quality improvement, chemical instruments and methods, and separation of dispersed particles, can solve the problems of low removal rate of flue gas pollutants and high operating costs, and achieve enhanced removal efficiency, Low operating cost and improved contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

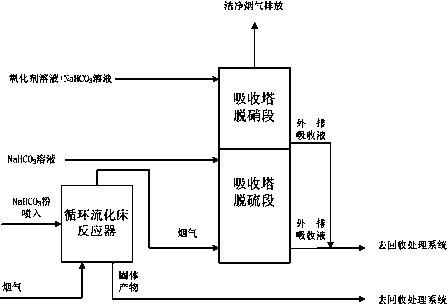

[0041] An integrated purification process for flue gas pollutant control, the specific steps are as follows:

[0042] A. The flue gas and sodium bicarbonate dry powder are continuously sent into the circulating fluidized bed reactor, and the flue gas makes the sodium bicarbonate dry powder in a fluidized state and reacts with it to initially remove sulfur oxides and nitrogen oxides in the flue gas;

[0043] B. Send the flue gas after preliminary desulfurization and denitrification in step A to the desulfurization section of the absorption tower, use sodium bicarbonate aqueous solution as the absorption liquid to spray from the upper part, and contact with the flue gas entering from the lower part in countercurrent, and remove the flue gas Sulfur oxides and other acidic components;

[0044] C. The desulfurized flue gas enters the denitrification section of the absorption tower, and the oxidant solution containing sodium bicarbonate is used as the absorption liquid to spray from...

Embodiment 2

[0046] An integrated purification process for flue gas pollutant control, the specific steps are as follows:

[0047] A. Spray sodium bicarbonate dry powder directly into the flue, react with flue gas, and initially remove sulfur oxides and nitrogen oxides;

[0048] B. Send the flue gas after preliminary desulfurization and denitrification in step A to the desulfurization section of the absorption tower, use sodium bicarbonate aqueous solution as the absorption liquid to spray from the upper part, and contact with the flue gas entering from the lower part in countercurrent, and remove the flue gas Sulfur oxides and other acidic components;

[0049] C. The desulfurized flue gas enters the denitrification section of the absorption tower, and the oxidant solution containing sodium bicarbonate is used as the absorption liquid to spray from the upper part to further remove nitrogen oxides in the flue gas. The purified flue gas is discharged from the absorption tower. Drain the top...

Embodiment 3

[0051] The implementation mode of this embodiment is basically the same as embodiment 1, on this basis:

[0052] The solid reaction product discharged from the bottom of the circulating fluidized bed reactor and the absorption liquid discharged from the bottom of the desulfurization section and denitrification section of the absorption tower are sent to the recovery treatment system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com