Preparation method and application of fluorine-boron codoped TiO2 nanosheets

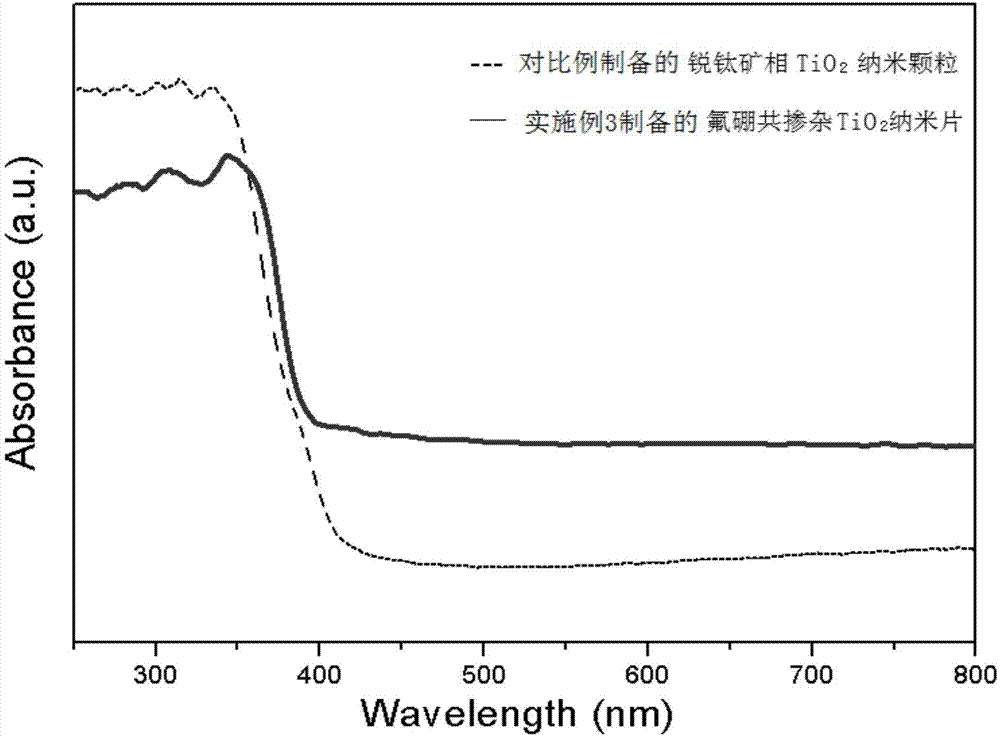

A nanosheet and co-doping technology, applied in nanomaterials and nanometer fields, can solve problems such as crystal face exposure of migration efficiency, and achieve the effect of improving photocatalytic performance, obvious catalytic effect, and improved absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

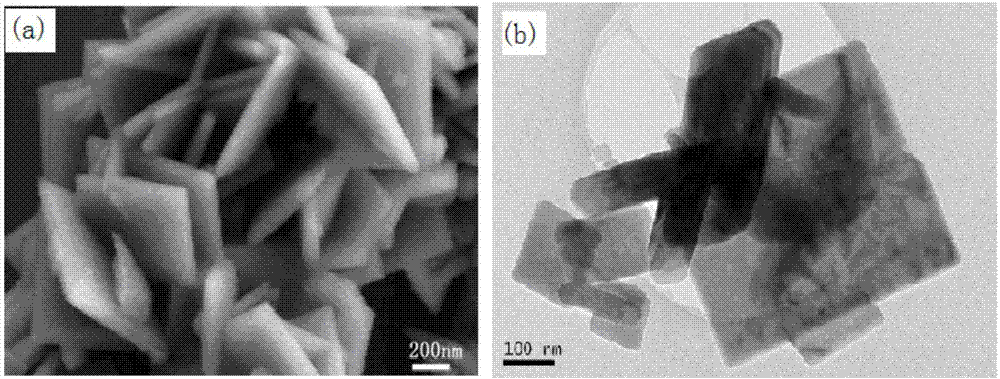

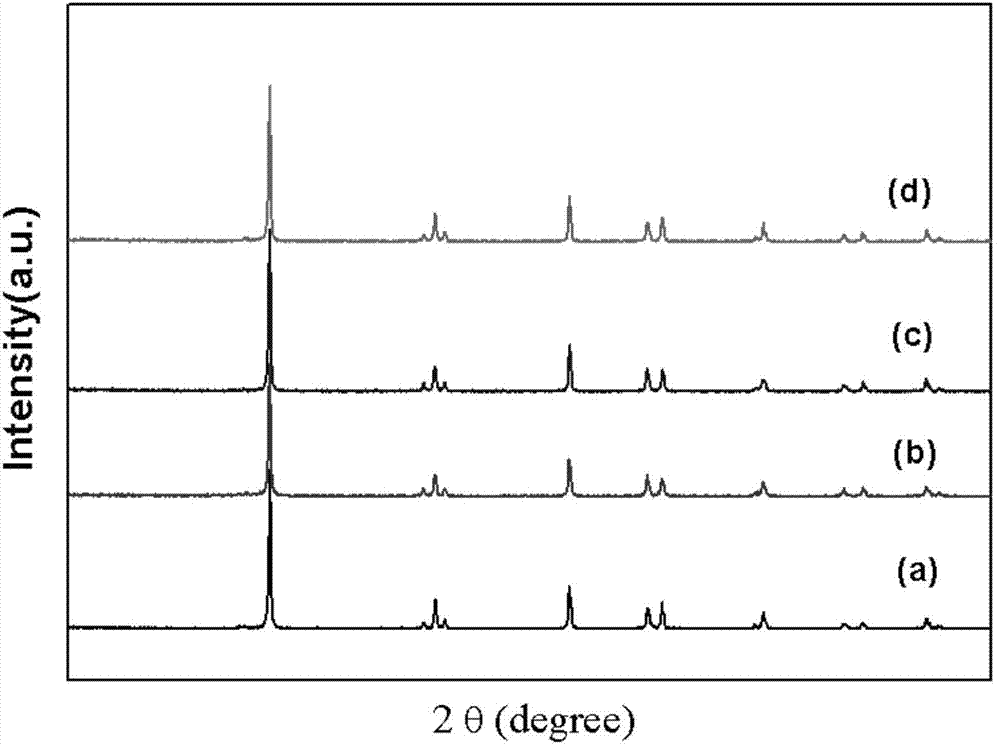

[0030] Measure a volume of 30ml ethanol solution as the precursor, slowly add 1ml of 15wt%TiCl 3Solution, stirred with a magnetic stirrer for 5 minutes to generate a uniform suspension; the solution prepared in the above steps was poured into a polytetrafluoroethylene autoclave liner with a volume of 50ml, and then 0.75ml of 40wt% HBF was added dropwise 4 The solution is put into the inner tank of the reaction kettle, and the temperature is kept at 210°C for 12 hours; the solid-liquid mixture obtained is subjected to solid-liquid centrifugation, washed 4 times with ethanol and dried at a constant temperature of 80°C for 10 hours; the obtained product is subjected to subsequent heat treatment at 450°C for 3 hours, Grinding into powder to obtain fluorine-boron co-doped with high degree of crystallization, (001) crystal plane exposed TiO 2 Nanosheets.

Embodiment 2

[0032] Measure a volume of 30ml ethanol solution as the precursor, slowly add 1ml of 15wt%TiCl 3 Solution, stirred with a magnetic stirrer for 5 minutes to generate a uniform suspension; pour the solution prepared in the above steps into a polytetrafluoroethylene autoclave liner with a volume of 50ml, and then drop 0 to 1ml of 40wt% HBF 4 Put the solution into the inner tank of the reaction kettle, and keep the temperature at 210°C for 12 hours; the solid-liquid mixture obtained is subjected to solid-liquid centrifugation, washed with ethanol three times and dried at a constant temperature of 80°C for 10 hours; the obtained product is subjected to subsequent heat treatment at 400°C for 4 hours, Grinding into powder to obtain fluorine-boron co-doped with high degree of crystallization, (001) crystal plane exposed TiO 2 Nanosheets.

Embodiment 3

[0034] Measure a volume of 30ml ethanol solution as the precursor, slowly add 1ml of 15wt%TiCl 3 Solution, stirred with a magnetic stirrer for 5 minutes to generate a uniform suspension; the solution prepared in the above steps was poured into a polytetrafluoroethylene autoclave liner with a volume of 50ml, and then 0.5ml of 40wt% HBF was added dropwise 4 The solution is put into the inner tank of the reaction kettle, and the temperature is kept at 210°C for 12 hours; the solid-liquid mixture obtained is subjected to solid-liquid centrifugation, washed with ethanol three times and dried at a constant temperature of 70°C for 10 hours; the obtained product is subjected to subsequent heat treatment at 400°C for 3 hours Grinding into powder to obtain fluorine-boron co-doped with high degree of crystallization, (001) crystal plane exposed TiO 2 Nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com