Preparation method of metal organic framework material film as well as product and application of metal organic framework material film

A metal-organic framework and film technology, which is applied in layered products, chemical instruments and methods, lamination devices, etc., can solve the problems of difficult production and application, long production cycle, difficult to produce dense films, etc. Large-scale promotion, good gas separation, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

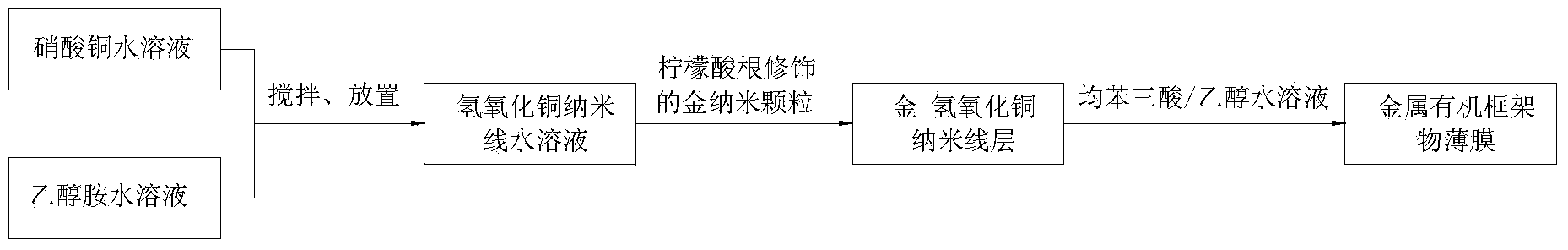

Method used

Image

Examples

Embodiment 1

[0036] 1) Under magnetic stirring, add 1.4mM ethanolamine aqueous solution to the same volume of 4mM copper nitrate aqueous solution. After 1 minute, slow down the stirring speed, and seal the reaction vessel. After 24 hours, a copper cadmium hydroxide nanowire solution is obtained;

[0037] 2) Mix 30ml nanowire solution with 1ml diameter 10nm at a concentration of 5.7×10 12 pcs / ml of citrate-modified gold nanoparticles (manufacturer: BBInternational) were evenly mixed, filtered to form a 600 thick gold-nanowire layer on the porous alumina membrane, and the diameter of the porous alumina membrane was 2.5cm , pore size 200nm, porosity 25-50%;

[0038] 3) Add the gold-nanowire layer to the trimesic acid / ethanol aqueous solution with a concentration of 10 5mM, the volume ratio of ethanol to water in the ethanol aqueous solution is 1:1, and react for two hours at room temperature to obtain a metal organic framework film.

[0039] The metal-organic framework film prepared in this...

Embodiment 2

[0041] 1) Under magnetic stirring, add 1.4mM ethanolamine aqueous solution to the same volume of 4mM copper nitrate aqueous solution. After 1 minute, slow down the stirring speed, and seal the reaction vessel. After 24 hours, a copper cadmium hydroxide nanowire solution is obtained;

[0042] 2) Mix 60ml nanowire solution with 2ml diameter 100nm at a concentration of 5.6×10 9 pcs / ml of citrate-modified gold nanoparticles (manufacturer: BBInternational) were uniformly mixed, filtered to form a 1200nm thick gold-nanowire layer on the porous alumina membrane, the diameter of the porous alumina membrane was 2.5cm , pore size 200nm, porosity 25-50%;

[0043] 3) Add the gold-nanowire layer to 20ml of trimesic acid / ethanol aqueous solution with a concentration of 5mM, the volume ratio of ethanol to water in the ethanol aqueous solution is 1:1, and react for two hours at room temperature to obtain a metal organic framework film.

[0044] The metal-organic framework film prepared in t...

Embodiment 3

[0046] 1) Under magnetic stirring, add 1.4mM ethanolamine aqueous solution to the same volume of 4mM copper nitrate aqueous solution. After 1 minute, slow down the stirring speed, and seal the reaction vessel. After 24 hours, a copper cadmium hydroxide nanowire solution is obtained;

[0047] 2) Mix 30ml nanowire solution with 1ml diameter 50nm at a concentration of 4.5×10 10 pcs / ml of citrate-modified gold nanoparticles (manufacturer: BBInternational) were evenly mixed, filtered to form a 600nm-thick gold-nanowire layer on the porous alumina membrane, and the diameter of the porous alumina membrane was 2.5cm , pore size 200nm, porosity 25-50%;

[0048] 3) Add the gold-nanowire layer to 10ml of trimesic acid / ethanol aqueous solution with a concentration of 5mM, the volume ratio of ethanol to water in the ethanol aqueous solution is 1:1, and react for two hours at room temperature to obtain a metal organic framework film.

[0049] figure 2 with 3 These are the surface SEM a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com