Bismuth gallate ferroelectric film material and preparation method thereof

A technology for ferroelectric thin films and thin film materials, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems that bulk materials cannot be used in the field of microelectronics, lack of preparation technology, unsuitable for devices, integrated circuits, etc. Achieve the effect of low cost, good repeatability and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] a. Preparation of bismuth gallate solution

[0023] Weigh 2.6948g of bismuth nitrate pentahydrate and 1.8205g of gallium nitrate hexahydrate, pour them into a 100ml flask, then add 50ml of acetic acid (analytical pure), then stir at a temperature of 60°C to dissolve them completely to obtain a concentration of 0.1M colorless transparent solution.

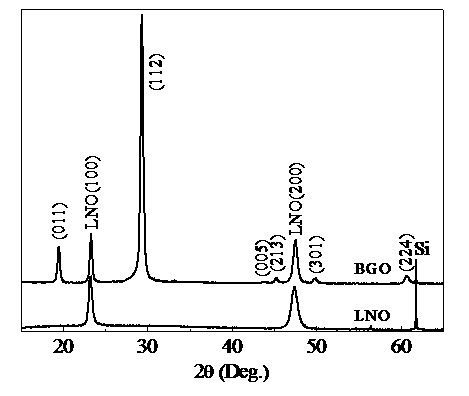

[0024] b. Preparation of bismuth gallate thin film material

[0025] (1) Drop the prepared solution onto the lanthanum nickelate substrate rotating at high speed, the substrate speed is 4000 rpm, and rotate for 25 seconds to obtain the raw material film;

[0026] (2) Segmented annealing: heat preservation at 200°C for 200 seconds, then pyrolysis at 400°C for 240 seconds, and finally high-temperature annealing at 700°C for 300 seconds;

[0027] (3) Repeat the above process 6 times to prepare a bismuth gallate thin film material with a thickness of 110 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com