Reaction-controlled phase transfer catalyst catalyzed propylene epoxidation to prepare propylene oxide

A technology for controlling phase transfer and propylene oxide, applied in organic chemistry and other directions, can solve problems such as process flow description, and achieve the effects of simple process, mild reaction conditions and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

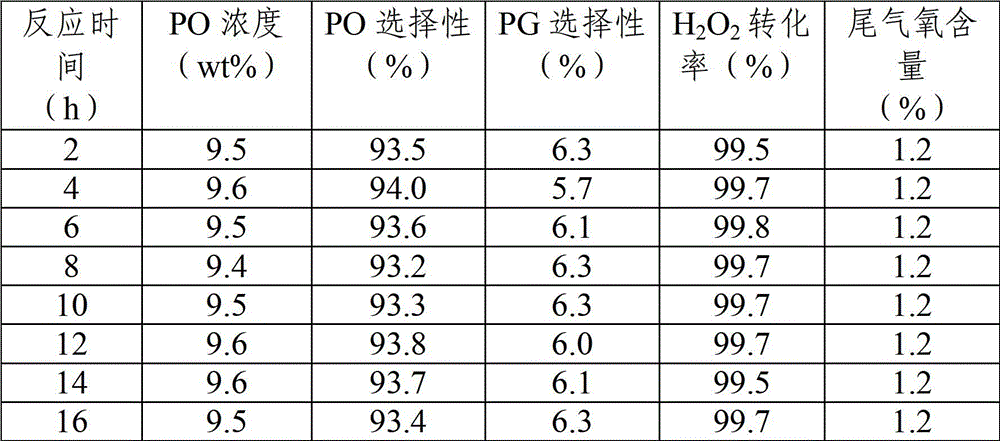

Embodiment 1

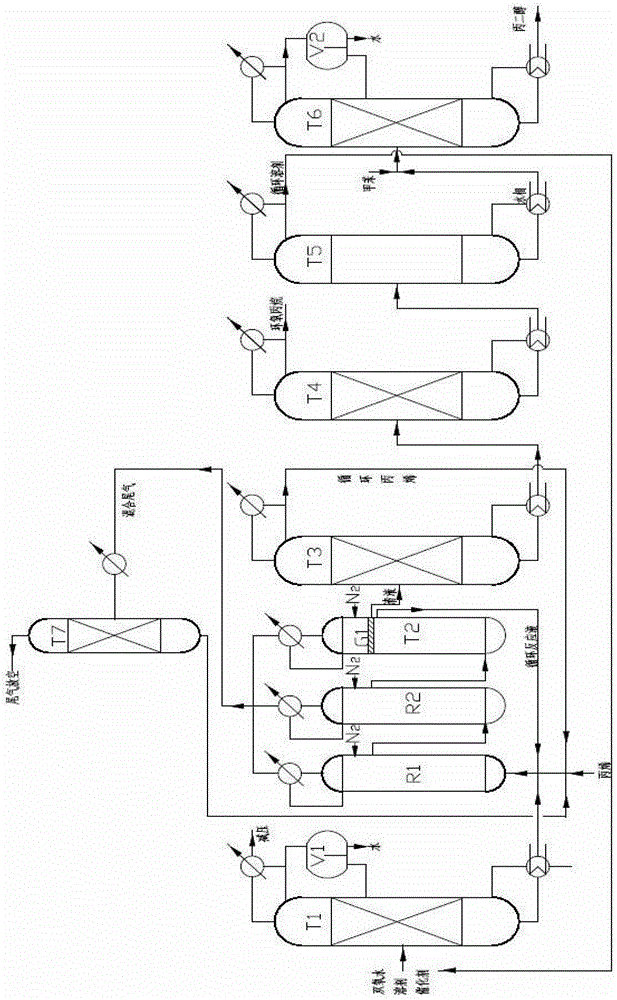

[0028] Such as figure 1 As shown, the solvent in the hydrogen peroxide dehydration tower T1 is a 1:1 equal-volume mixture of toluene and trioctyl phosphate, the feed flow rate is 5.0 kg / h, the feed flow rate of 35% hydrogen peroxide is 2.0 kg / h, and the catalyst feed rate is 0.4 kg / h. The hydrogen peroxide dehydration process conditions of tower T1 are as follows: the temperature at the bottom of the tower is 45°C, the condensation temperature at the top of the tower is -5°C, and the pressure is 1000Pa.

[0029] The reaction liquid obtained from T1 is transported to the continuous tank reactor R1 at 6.0kg / h and propylene at 0.5kg / h. The reaction conditions of the continuous tank reactors R1 and R2 are as follows: the reaction temperature is 85°C, and the reaction pressure is 4.25Mpa. The reaction space velocity is 4h -1 . After the reaction of R2, the material passes through the condensation filter tower T2, and the circulating reaction liquid containing the catalyst is ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com