Separating and recycling method for atom transfer radical polymerization catalyst

A polymerization catalyst and atom transfer technology, applied in the direction of chemical recovery, etc., can solve the problems of inapplicability and limited use range, etc., achieve the effect of fast separation time, broaden the use range, and avoid the post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment one: a kind of atom transfer radical polymerization catalyst separation and recycling method, used chemical reagent is:

[0027] Methyl methacrylate (MMA), 99%, China Pharmaceutical (Group) Shanghai Chemical Reagent Company; Azobisisobutyronitrile, 99%, ethyl α-bromophenylacetate (ie ethyl 2-bromophenylacetate) , 98%, China National Pharmaceutical (Group) Shanghai Chemical Reagent Company; polyethylene glycol (molecular weight: 200), vitamin C (ascorbic acid, VC), analytically pure, sodium ascorbate (VCNa), analytically pure, tris[(2-pyridine Base) methyl] amine, 99%, China National Pharmaceutical (Group) Shanghai Chemical Reagent Company; solvents such as tetrahydrofuran (THF), toluene, p-xylene, o-xylene and methanol, analytically pure, China National Pharmaceutical (Group) Shanghai Chemical Reagent company.

[0028] Test equipment and conditions:

[0029] Gel Permeation Chromatography: Model 1515 GPC from Waters, USA.

[0030] Determination conditions: ...

Embodiment 2

[0035] Embodiment two: Catalyst is separated and recycled from generating polymer:

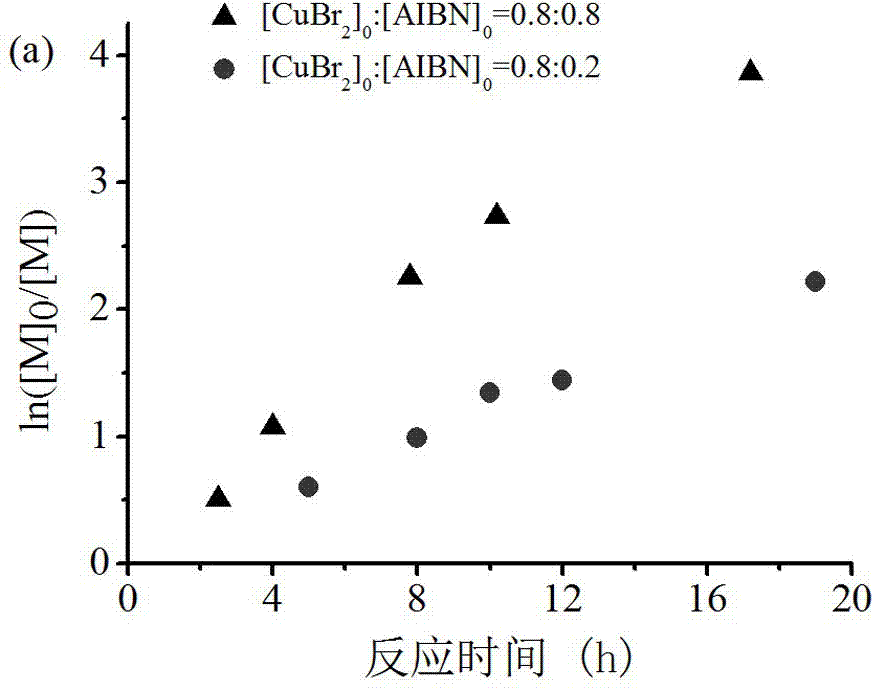

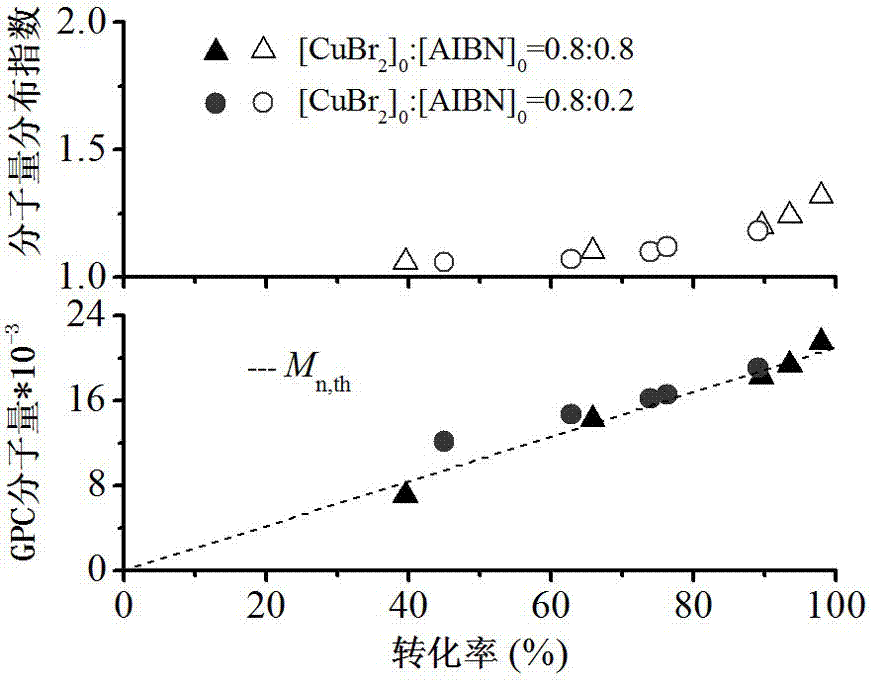

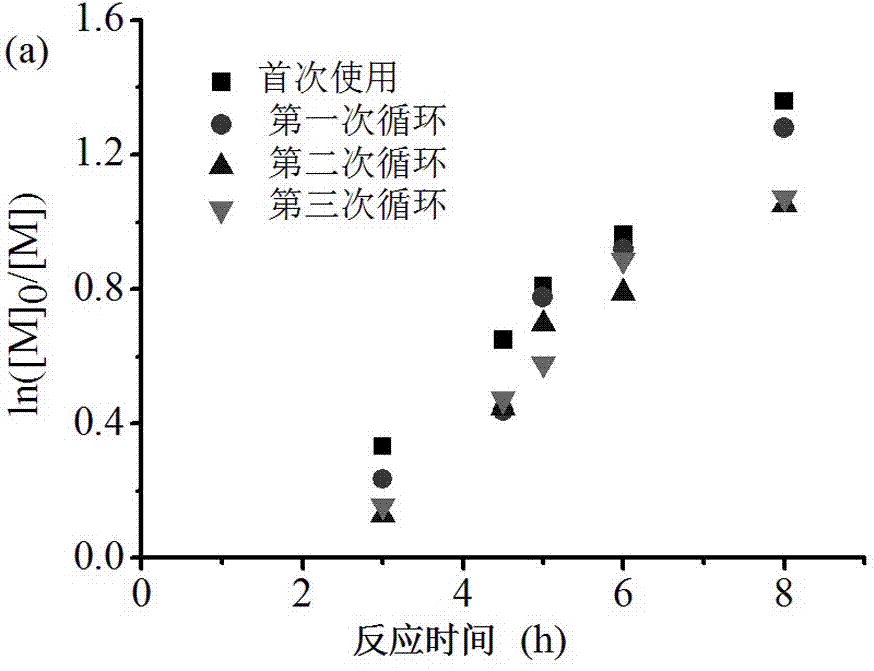

[0036] According to the molar ratio n(MMA):n(initiator):n(CuBr 2 ) : n (ligand): n (AIBN) = 200:1:0.8:2.4:0.8, add CuBr in turn 2 , ligand, MMA (1 mL), initiator, AIBN, polyethylene glycol 200, p-xylene in a 5 mL ampoule, and seal the tube under an inert gas Ar atmosphere. Place the sealed ampoule in an oil bath at a constant temperature (70°C) for a predetermined time to react. The reaction proceeds in homogeneous phase. End the reaction respectively according to the set reaction time. After the end, take out the sealed tube, cool it to room temperature with cold water, open the sealed tube, separate the two phases, dissolve the organic phase with 2~5 mL of tetrahydrofuran, pour it into 250 mL of methanol and let it stand overnight, then suction filter, wash with water, and dry in vacuum Polymethyl methacrylates of different molecular weights can be obtained by drying. The polyethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com