Preparation method of tartaric acid and citric acid compound nitrogen-doped fluorescent polymer nano point

A fluorescent polymer, tartaric acid technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of cumbersome synthesis route, toxicity of raw materials, and few effective methods, and achieve the effect of easy method and easy amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of tartaric acid and citric acid composite nitrogen-doped fluorescent polymer nano-dot is characterized in that comprising the following steps:

[0035] Step 1, weighing raw materials

[0036] Weigh 1.5-3.0g L-tartaric acid and 0-1.5g citric acid in a three-necked bottle;

[0037] Step 2, heating reaction

[0038] Add 10-30ml of oleic acid and 0.3-5ml of ethylenediamine into the three-necked bottle in step 1, heat to 180-250 degrees while stirring, stop the reaction after keeping warm for 10-60min, and put the three-necked bottle while it is hot The reaction solution in the mixture was poured into a beaker, and the heating rate was 15° C. / min.

[0039] Step three, washing

[0040] The reaction solution prepared in step 2 was fully washed successively with three washing solutions of n-hexane, ethanol and chloroform, each of the three washing solutions was washed 5 times, each time the amount was 10 ml, soaked for 10 minutes, and then filte...

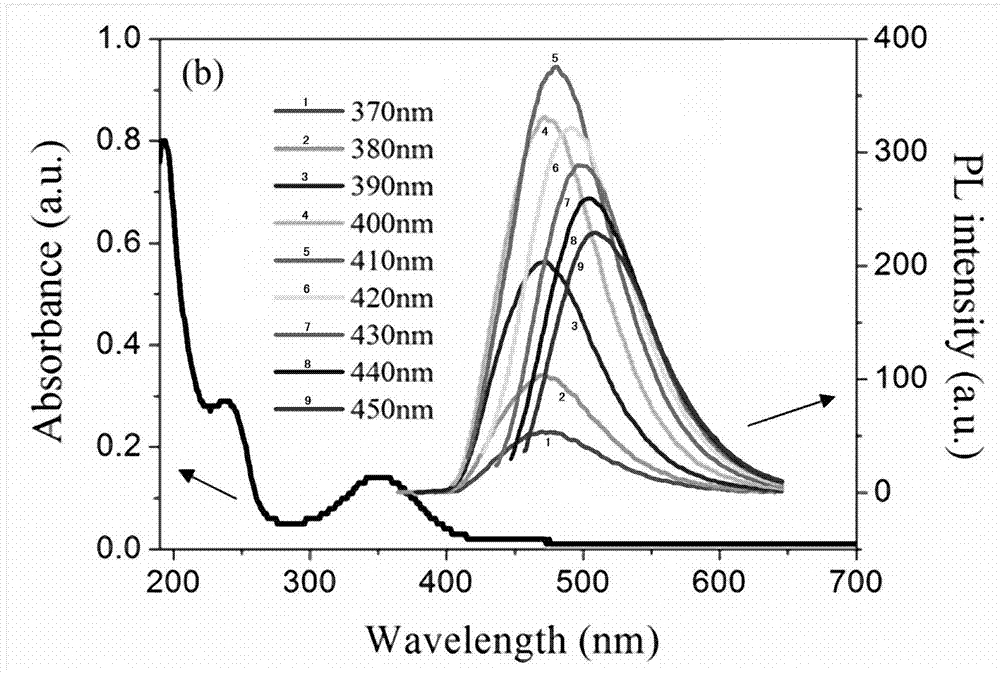

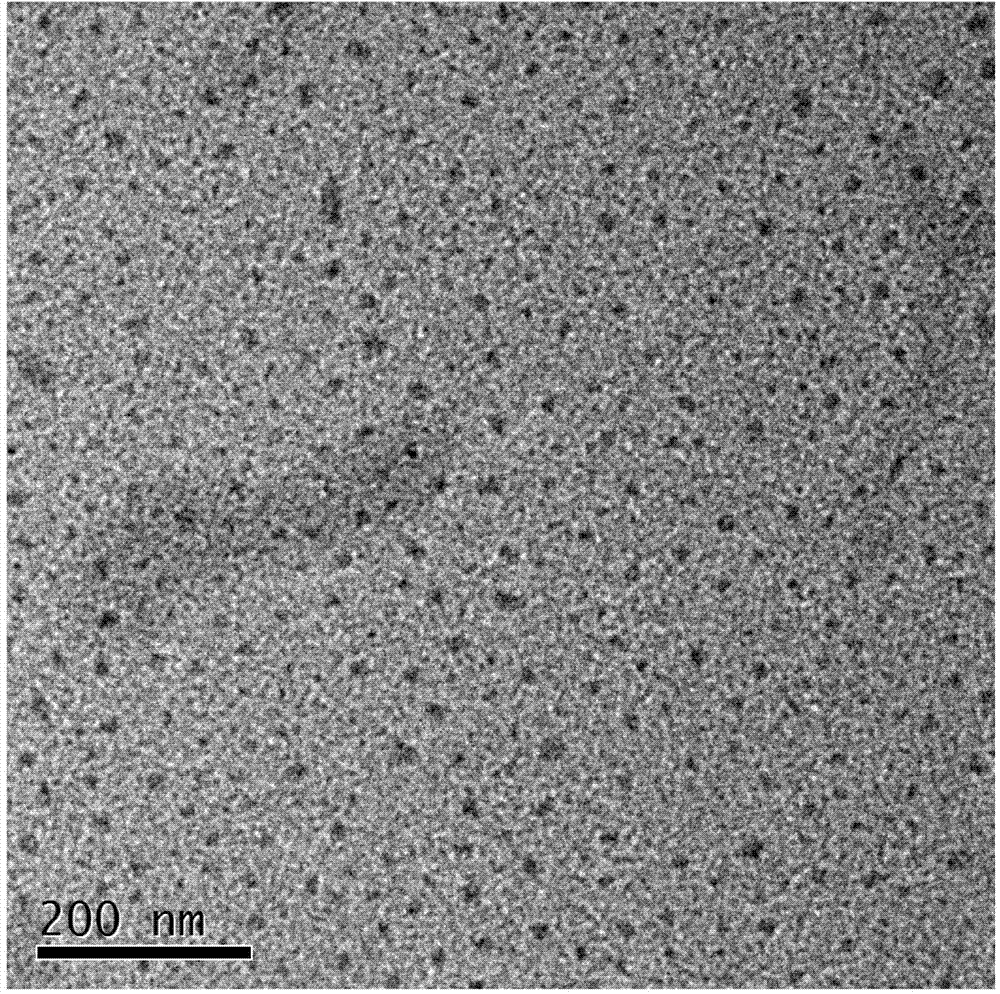

Embodiment 1

[0052] Weigh 1.5g of citric acid and 1.5g of L-tartaric acid into a three-necked bottle, add 30ml of oleic acid and 5ml of ethylenediamine, stir and heat, and set the temperature to 220 degrees. When the temperature rose to 150°C, the solid dissolved and the solution began to boil. The color gradually changed from colorless to brown, and then dark brown as the reaction progressed. The reaction was stopped after 30 minutes, and the reaction solution was poured out while it was hot. The product was washed thoroughly with n-hexane, ethanol and chloroform in sequence, and dried in vacuum at 50 degrees to obtain tartaric acid and citric acid composite nitrogen-doped fluorescent polymer nanodots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com