Production method of ice orange fruit wine

A production method and fruit wine technology are applied in the production field of ice citrus fruit wine, which can solve the problems of clogging of adsorbent, increase production cost, poor taste, etc., and achieve the effects of reducing the content of bitter substances, reducing production cost, and eliminating the debittering process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 100kg of oranges harvested after frost, peeled, refrigerated at minus 5°C for 24 hours, and squeezed juice at minus 5°C to obtain orange juice and pomace with a reducing sugar content of 275g / L.

[0031] (2) Mix orange juice and pure water in a ratio of 10:3, adjust the sugar content of the mixture to 21.0%, pH to 3.7, add 2.5g / L of activated fruit wine dry yeast, adjust the temperature of the fermentation liquid to about 15°C, and control The fermentation temperature is 20°C-28°C, and the fermentation is carried out for 7 days to obtain a fermentation broth with an alcohol content of 12.1%.

[0032] (3) Filtration of the fermentation broth to obtain a filtrate.

[0033] (4) Store the filtrate in a storage tank, control the temperature to be 15°C-25°C, age for 60 days, and obtain the base wine after filtration.

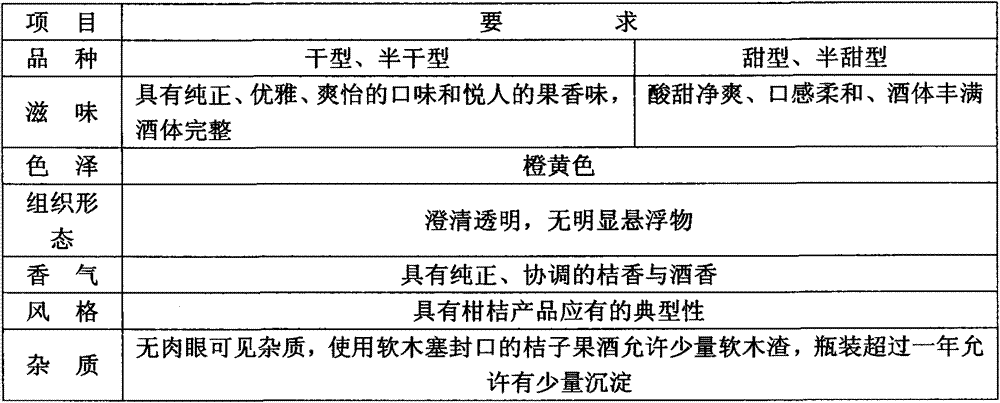

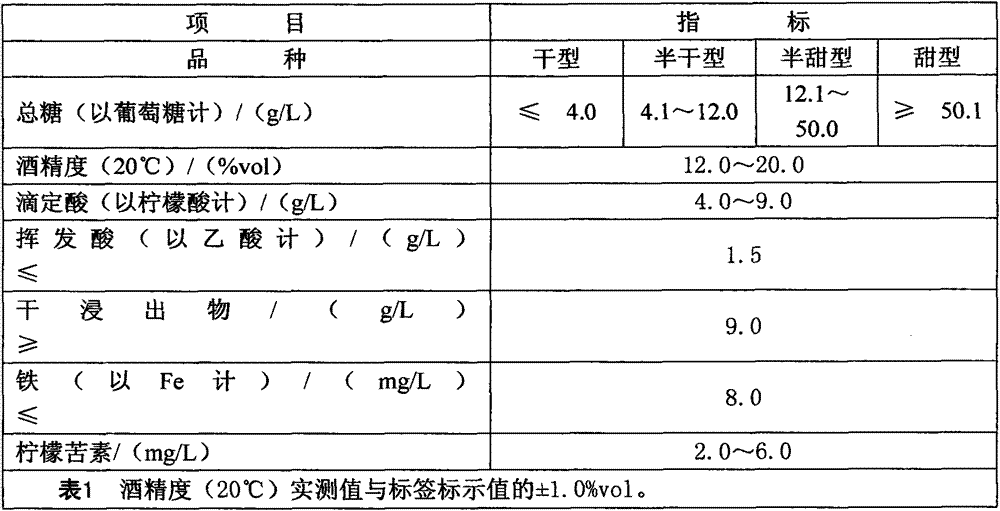

[0034] (5) The base wine is prepared in accordance with the "People's Republic of China Agricultural Industry Standard-Green Food and Fruit Wine Stan...

Embodiment 2

[0036] (1) Take 100kg of oranges harvested after frost, peeled, refrigerated at -8°C for 24 hours, and squeezed at -8°C to obtain orange juice and pomace with a reducing sugar content of 220g / L.

[0037] (2) Adjust the pH of the orange juice to 3.7, add 2.0g / L of activated fruit wine dry yeast, adjust the temperature of the fermentation liquid to about 15°C, control the fermentation temperature to be 20°C-28°C, and ferment for 7 days. The alcohol content is 12.3% main broth.

[0038] (3) filtering the main fermentation broth to obtain a filtrate. The filtrate is stored in a storage tank, and the temperature is controlled to be 15°C-25°C, aged for 60 days, and the base wine is obtained after filtration.

[0039] (4) The base wine is prepared in accordance with the "People's Republic of China Agricultural Industry Standard-Green Food and Fruit Wine Standard" (NY / T1508-2007) to obtain orange wine. The obtained citrus sensory and physicochemical indexes are shown in Table 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com