Method for producing ultralow-rigidity annealing-free cold forging steel

A production method and technology for cold heading steel, applied in the field of metal materials and processing, and cold heading steel production, can solve problems such as fatigue performance affecting the surface quality of fasteners, pollute the environment, surface decarburization, etc., and achieve improved temperature and controlled rolling. technology, reduce environmental pressure, and improve the effect of product plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

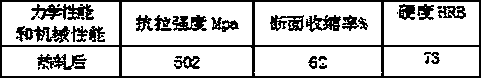

[0014] As a specific embodiment of the present invention, the aforementioned ultra-low hardness annealing-free cold heading steel production method, wherein the composition of the cold heading steel is as follows: C content is 0.19%, Si content is 0.07%, Mn content is 0.84%, B content is 0.0023%, Ti content is 0.034%, P content is 0.013%, S content is 0.001%, Alt content is 0.029%, and the balance is Fe and unavoidable impurities. The cooling process of the roller table is to control the speed of the roller table to 0.150-0.320 m / s, and the specification of the cold heading steel is Φ8mm. After adopting this production method and component proportion, the mechanical properties and mechanical properties of the finished product after hot rolling are as follows:

[0015]

[0016] The mechanical properties and mechanical properties can fully meet the requirements of annealing-free 8.8 grade cold heading steel.

[0017] The microstructure is ferrite and pearlite, the ferrite co...

Embodiment 2

[0019] As a specific embodiment of the present invention, the aforementioned ultra-low hardness annealing-free cold heading steel production method, wherein the composition of the cold heading steel is as follows: C content is 0.20%, Si content is 0.07%, Mn content is 0.85%, B content is 0.0028%, Ti content is 0.036%, P content is 0.013%, S content is 0.001%, Alt content is 0.027%, and the balance is Fe and unavoidable impurities. The cooling process of the roller table is to control the speed of the roller table to 0.150-0.320 m / s, and the specification of the cold heading steel is Φ16mm. After adopting this production method and component proportion, the mechanical properties and mechanical properties of the finished product after hot rolling are as follows:

[0020]

[0021] The mechanical properties and mechanical properties can fully meet the requirements of annealing-free 8.8 grade cold heading steel.

[0022] The microstructure is ferrite and pearlite, the ferrite c...

Embodiment 3

[0024] As a specific embodiment of the present invention, the aforementioned ultra-low hardness annealing-free cold heading steel production method, wherein the composition of the cold heading steel is as follows: C content is 0.21%, Si content is 0.07%, Mn content is 0.95%, B content is 0.0023%, Ti content is 0.036%, P content is 0.011%, S content is 0.001%, Alt content is 0.025%, and the balance is Fe and unavoidable impurities. The cooling process of the roller table is to control the speed of the roller table to 0.220-0.440 m / s, and the specification of the cold heading steel is Φ22mm. After adopting this production method and component proportion, the mechanical properties and mechanical properties of the finished product after hot rolling are as follows:

[0025]

[0026] The mechanical properties and mechanical properties can fully meet the requirements of annealing-free 8.8 grade cold heading steel.

[0027] The microstructure is ferrite and pearlite, the ferrite c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com