High-shrinkage superfine acrylic fiber and preparation method thereof

An acrylic fiber and high-shrinkage technology, which is applied in the field of high-shrinkage ultra-fine acrylic fiber and its preparation, can solve the problems of large-scale production of ultra-fine acrylic fiber, etc., and achieve good air permeability and drape performance, high bending stiffness, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

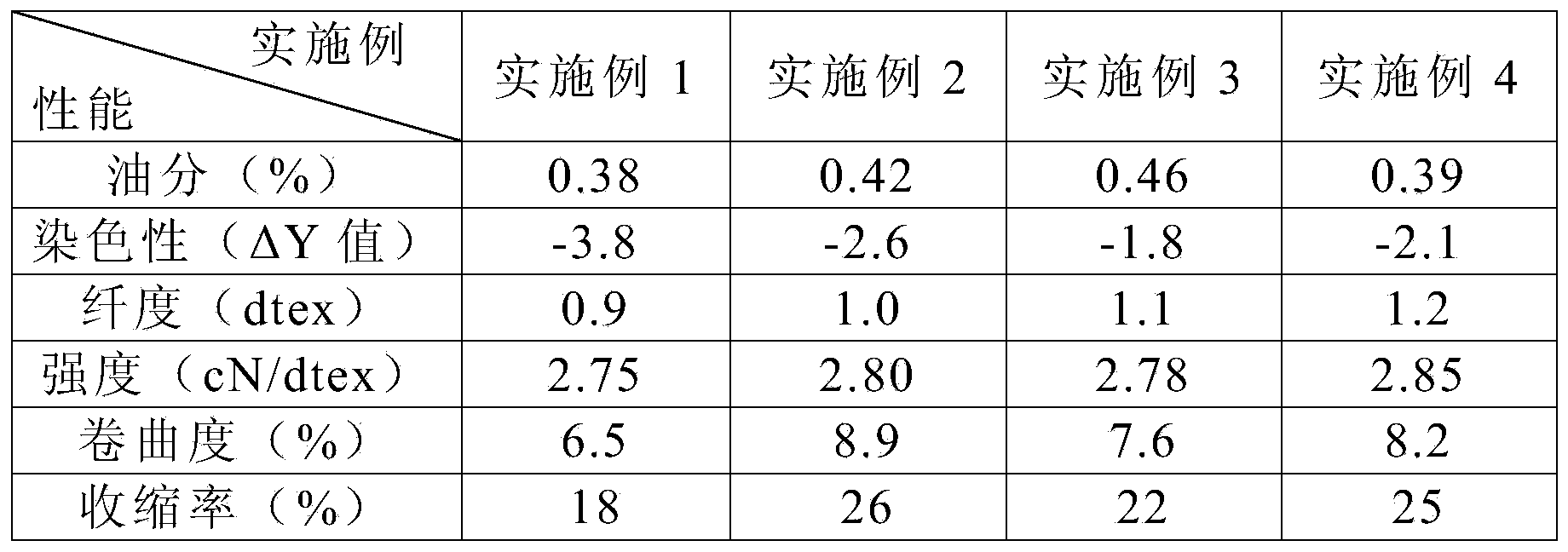

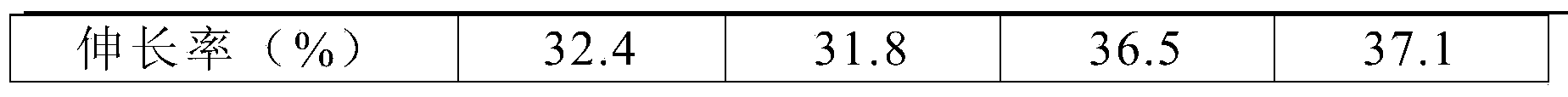

Embodiment 1

[0034] Copolymerize 91% acrylonitrile and 9% vinyl acetate under the catalysis of persulfate and sulfite to make polypropylene dry powder with a molecular weight of 60,000-70,000, and dissolve the polypropylene dry powder in the solvent dimethyl formaldehyde A stock solution with a concentration of 20% is formed in the amide, and the stock solution is heated to 82°C by a heater, and the heated stock solution is extruded from the rectangular hole of the spinneret, and the as-spun fiber is formed by double diffusion in the coagulation bath; among them, entering The temperature of the stock solution in the coagulation bath is 80°C, the temperature of the coagulation bath is 30°C, the concentration of the coagulation bath is 30%, and the circulation volume is 28KL / h. The number of spinneret holes is 90000.

[0035] Washing and drafting: After washing the above-mentioned primary fibers, they are drawn by a drafting machine. During washing, the temperature of the water tank is 80°C,...

Embodiment 2

[0040] Copolymerize 92% acrylonitrile and 8% vinyl acetate under the catalysis of persulfate and sulfite to make polypropylene dry powder with a molecular weight of 70,000-80,000, and dissolve the polypropylene dry powder in the solvent dimethyl formaldehyde A stock solution with a concentration of 22% is formed in the amide, and the stock solution is heated to 84°C by a heater, and the heated stock solution is extruded from the rectangular hole of the spinneret, and the primary fiber is formed by double diffusion in the coagulation bath; among them, enter The temperature of the stock solution in the coagulation bath is 82°C, the temperature of the coagulation bath is 35°C, the concentration of the coagulation bath is 38%, and the circulation volume is 30KL / h. The number of spinneret holes is 100,000.

[0041] Washing and drawing: After washing the above-mentioned primary fibers, they are drawn by a drafting machine. During washing, the temperature of the water tank is 85°C, t...

Embodiment 3

[0046] Copolymerize 93% acrylonitrile and 7% vinyl acetate under the catalysis of persulfate and sulfite to make polypropylene dry powder with a molecular weight of 80,000-90,000, and dissolve the polypropylene dry powder in the solvent dimethyl formaldehyde A stock solution with a concentration of 23% is formed in the amide, and the stock solution is heated to 88°C by a heater, and the heated stock solution is extruded from the rectangular hole of the spinneret, and the as-spun fiber is formed by double diffusion in the coagulation bath; among them, entering The temperature of the stock solution in the coagulation bath is 88°C, the temperature of the coagulation bath is 40°C, the concentration of the coagulation bath is 50%, and the circulation volume is 32KL / h. The number of spinneret holes is 100,000.

[0047] Washing and drafting: After washing the above-mentioned primary fibers, they are drawn by a drafting machine. During washing, the temperature of the water tank is 88°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com