High-resistance and low-dislocation GaN thin film and preparation method

A low-dislocation, high-resistance technology, applied in chemical instruments and methods, circuits, electrical components, etc., can solve problems such as reducing the quality of epitaxial film crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

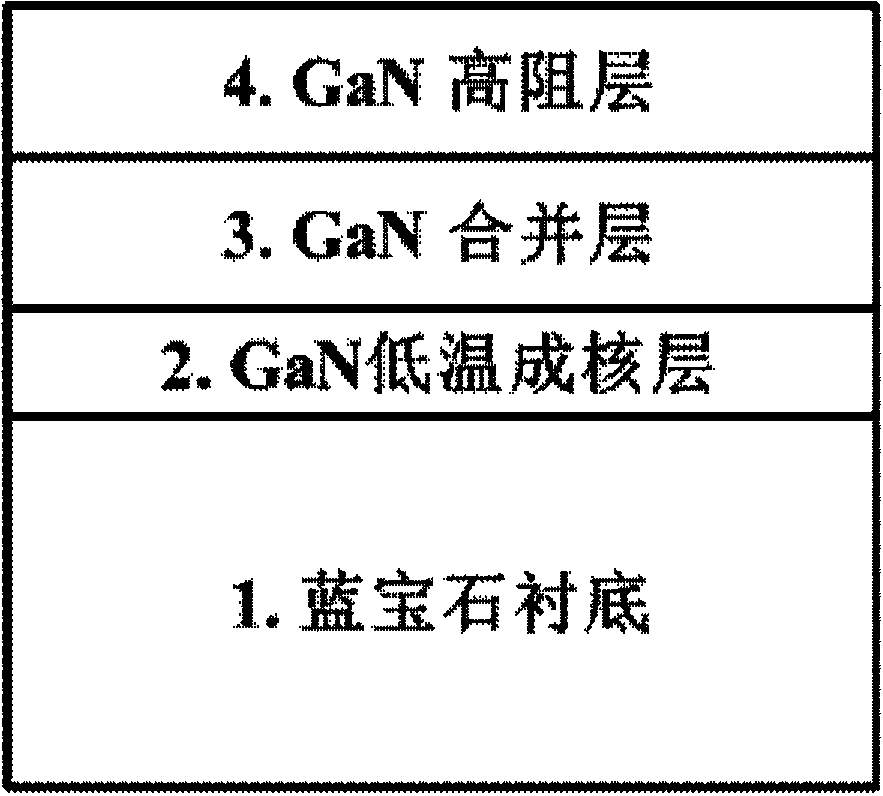

[0019] See figure 1 As shown, the present invention provides a high resistance low dislocation GaN film, including:

[0020] A substrate 1, the material of which is sapphire;

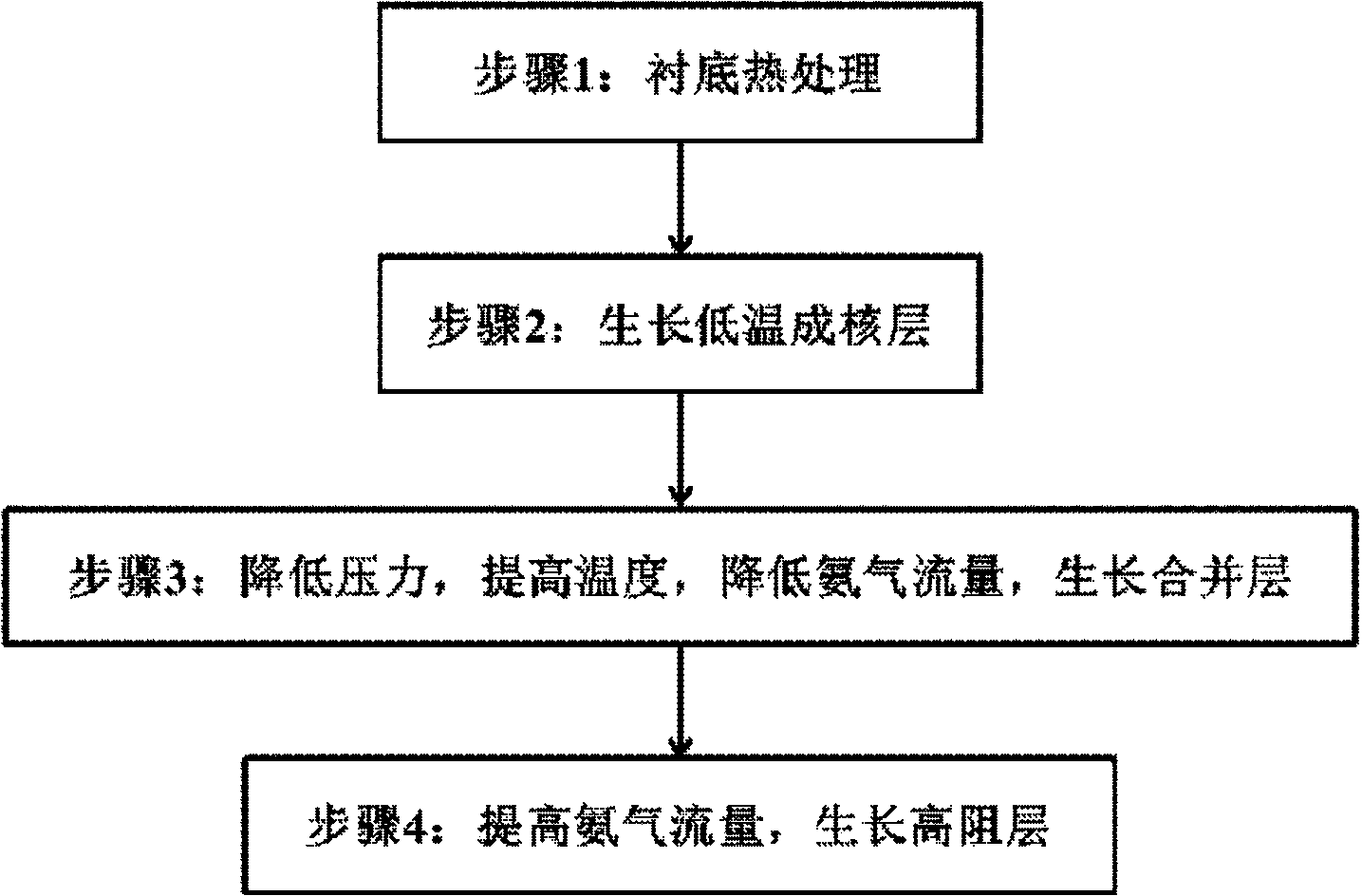

[0021] A GaN low-temperature nucleation layer 2 fabricated on the substrate 1. The growth temperature of the GaN low-temperature nucleation layer 2 is 500°C and 600°C, the pressure of the reaction chamber is 450550 Torr, and the thickness is 1525 nm;

[0022] A GaN combined layer 3, which is fabricated on the GaN low-temperature nucleation layer 2. The growth temperature of the GaN combined layer 3 is 1000-1100°C, the reaction chamber pressure is 40-100 Torr, the ammonia flow rate is 0.2-1 SLM, and the thickness is 700-800nm;

[0023] The purpose of merging layer 3 is to reduce the dislocation density of the material and improve the quality of the material. The purpose of reducing the ammonia flow rate in the merged layer 3 is to make the material grow faster in the longitudinal direction than in the transvers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com