A kind of bionic composite patch and its preparation method and application

A patch, the other side of the technology, applied in the field of bionic regenerative repair absorbable degradable patch preparation, can solve the problems of collagen sponge not soft, poor tissue attachment performance, calcification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

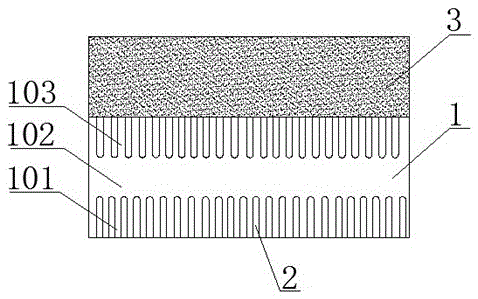

Image

Examples

Embodiment 1

[0017] 1. Preparation of cell induction layer:

[0018] Dissolve 2g PDLLA (Mη=80,000) and 0.48g PLLA (Mη=80,000) in 30ml ethyl acetate, then mix into lecithin, the mixing ratio (mass percentage) of it and polylactic acid material is 4 / 100, stir for 24h . The polymer solution was evenly poured into the mold, and when the film was formed, vacuum was applied at 45°C for 24 hours to prepare the isolation film. Laser drilling on the film: the hole diameter is 150 μm, the distance between holes is 200 μm, the depth is 0.1 mm, and the thickness is 0.3 mm.

[0019] 2. Cell anti-seepage layer preparation: 2gPDLLA (Mη=80,000) and 0.48gPLLA (Mη=80,000) were dissolved in 50ml of dichloromethane, stirred for 24 hours, then mixed with lecithin, and mixed with polylactic acid material The ratio (mass percentage) is 4 / 100. In an environment with a humidity of 45-65% and a temperature of 18-28° C., the electrospun membrane is obtained by electrospinning with an electrospun diameter of 150 n...

Embodiment 2

[0024] 1. Preparation of cell induction layer:

[0025] Dissolve 3gPDLLA (Mn=80,000) and 0.41gPLLA (Mn=80,000) in 30ml ethyl acetate, then mix into lecithin, its mixing ratio (mass percentage) with polylactic acid material is 13 / 100 respectively, stir 24h. Pour the polymer solution evenly into the mold, and when the film is formed, vacuumize at 45° C. for 24 hours to prepare a separator with a hole on one side and a smooth side on the other. Laser drilling on the film: the hole diameter is 100 μm, the distance between holes is 200 μm, the depth is 0.1 mm, and the thickness is 0.3 mm.

[0026] 2. Cell anti-seepage layer preparation: 3gPDLLA (Mη=80,000) and 0.41gPLLA (Mη=80,000) were dissolved in 50ml of dichloromethane, stirred for 24 hours, then mixed into lecithin, and its mixing with polylactic acid material The ratio (mass percentage) was 13 / 100 respectively, and stirred for 24 hours. In an environment with a humidity of 45-65% and a temperature of 18-28° C., the electro...

Embodiment 3

[0030] 1. Preparation of cell induction layer:

[0031] Dissolve 3gPDLLA (Mn=80,000) and 0.41gPLLA (Mn=80,000) in 30ml ethyl acetate, then mix into lecithin, its mixing ratio (mass percentage) with polylactic acid material is 9 / 100 respectively, stir 24h. Pour the polymer solution evenly into the mold, and when the film is formed, vacuumize at 45° C. for 24 hours to prepare a separator with a hole on one side and a smooth side on the other. . Laser drilling on the film: the hole diameter is 100 μm, the distance between the holes is 200 μm, and the depth is 0.1 mm. The thickness is 0.3mm.

[0032] 2. Cell anti-seepage layer preparation: 3gPDLLA (Mη=80,000) and 0.41gPLLA (Mη=80,000) were dissolved in 50ml of dichloromethane, stirred for 24 hours, then mixed into lecithin, and its mixing with polylactic acid material The ratio (mass percentage) was 9 / 100 respectively, and stirred for 24 hours. In an environment with a humidity of 45-65% and a temperature of 18-28° C., the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com