A method for improving the toughness of calcium phosphate bone cement

A technology of calcium phosphate bone cement and calcium phosphate powder, applied in medical science, prosthesis and other directions, can solve the problems of human harm, uncontrollable degradation rate, non-degradation of reinforcing fibers, etc., to achieve accelerated degradation, good biocompatibility, The effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

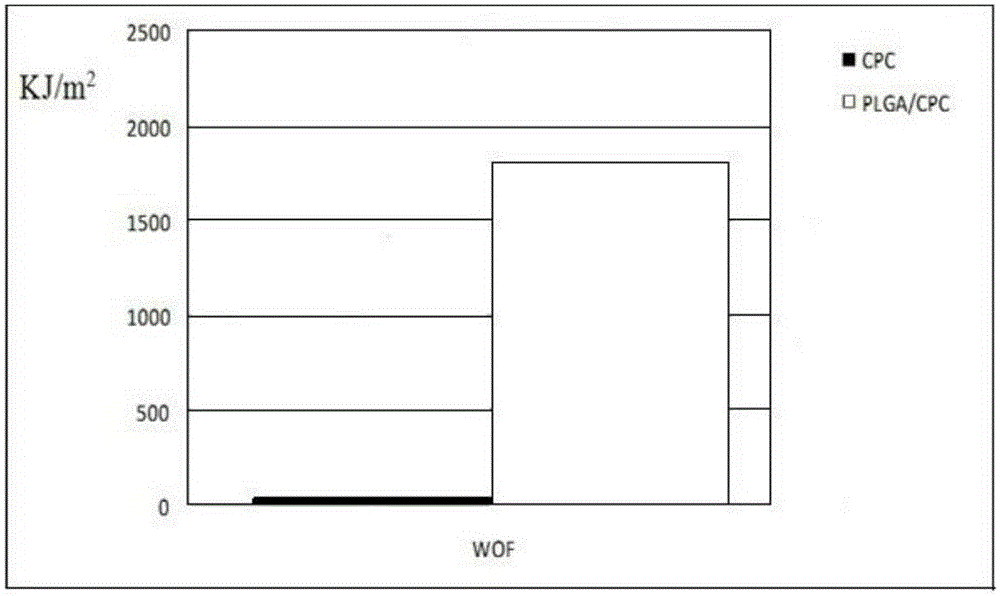

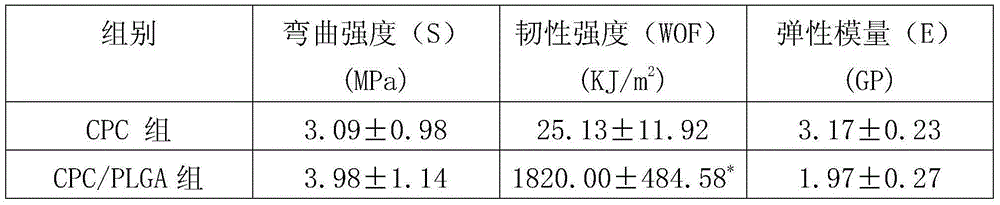

Image

Examples

Embodiment 1

[0018] Take calcium phosphate bone cement (CPC, the solid phase is calcium phosphate powder, purchased from Shanghai Ruibang Biomaterials Co., Ltd.), and the liquid phase is 2% Na 2 HPO 4 solution. Mix 1 g of calcium phosphate powder with 0.3 mL of 2% Na 2 HPO 4 The solution was mixed to prepare a thin paste of CPC, and the mixture was smeared on the surface of an electrospun PLGA nanofiber membrane (provided by the Biomaterials Center of the Netherlands Dental Academy) with a length of 20 mm and a width of 20 mm, with a thickness of 0.3 mm, and the PLGA nanofiber membrane Roll coaxially from one end to the other end, roll into a cylinder, put it into a mold filled with a little thin paste CPC in advance, clean up the CPC paste overflowing the mold, and place the test piece in a constant temperature water bath box with a constant temperature of 37°C and 100% relative humidity After 24 hours of curing, demould and take out the test piece. Example 2

Embodiment 2

[0019] Take calcium phosphate bone cement (CPC, the solid phase is calcium phosphate powder, purchased from Shanghai Ruibang Biomaterials Co., Ltd.), and the liquid phase is 2% Na 2 HPO 4 solution. Mix 1 g of calcium phosphate powder with 0.3 mL of 2% Na 2 HPO 4 The solution was mixed to prepare a thin paste of CPC, and the mixture was smeared on the surface of an electrospun PLGA nanofiber membrane (provided by the Biomaterials Center of the Netherlands Dental Academy) with a length of 20 mm and a width of 20 mm, with a thickness of 1 mm. The PLGA nanofiber membrane was made of One end is coaxially rolled to the other end, rolled into a cylinder, put into the mold, and the CPC paste overflowing the mold is cleaned. The specimen was cured in a constant temperature water bath box with a constant temperature of 37°C and a relative humidity of 100% for 24 hours, and then demoulded, and the specimen was taken out.

[0020] The following are the specific experimental methods an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com