Membrane separation device and method for purifying after-treatment mother liquor

A technology for membrane separation and mother liquor, applied in separation methods, chemical instruments and methods, semipermeable membrane separation, etc., can solve the problems of increased investment and production costs, sulfolane ring opening, waste liquid and slag, etc., to achieve strong continuity, Simple operation, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

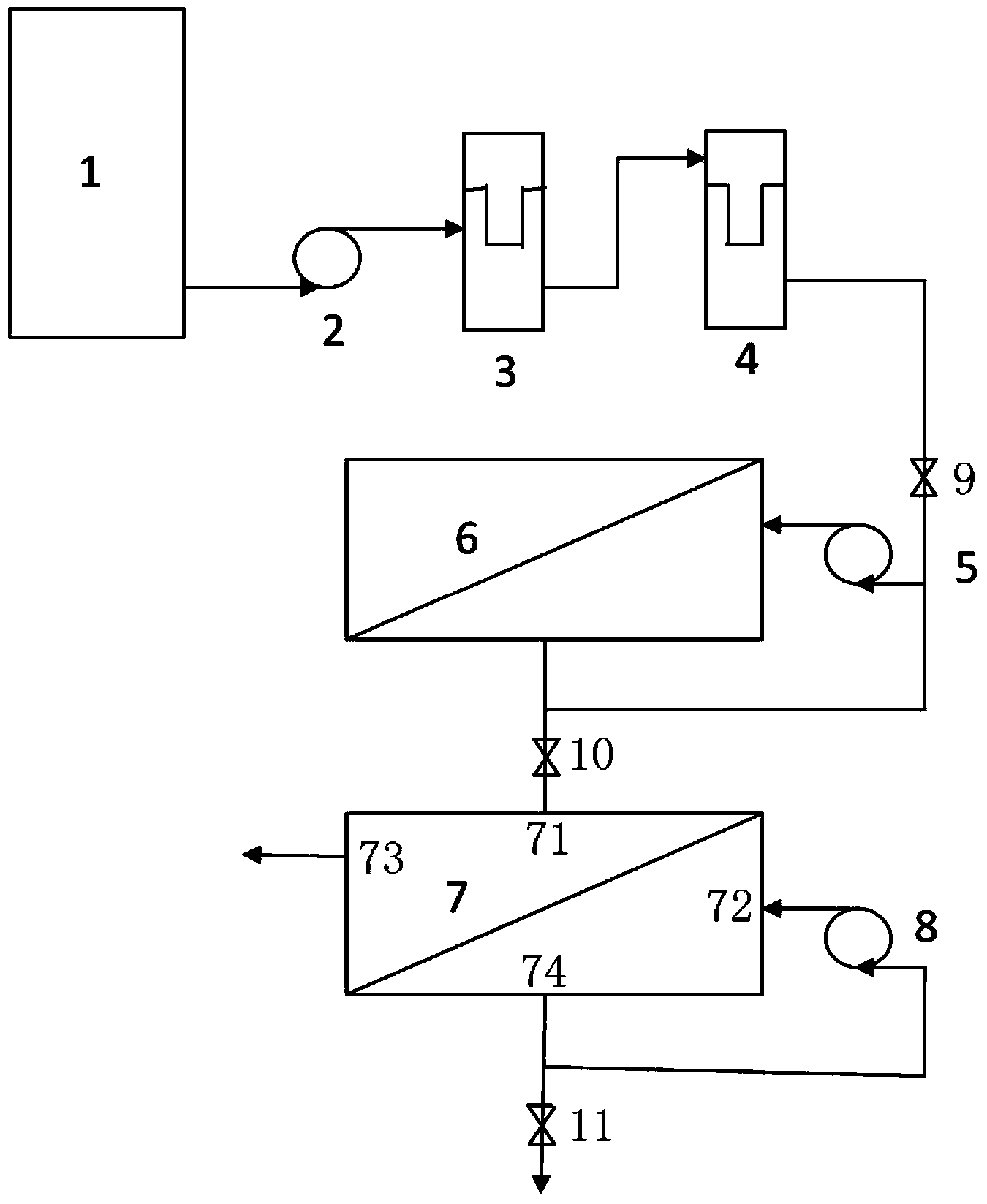

[0031] figure 1 As shown, a membrane separation device for purifying and post-processing mother liquor includes a solvent tank to be recovered, a feed pump, a basket filter, an activated carbon column filter, a first valve, a first high-pressure pump, a reverse osmosis Membrane device, second valve, permeation membrane distillation device, third valve. Wherein, the outlet of the reverse osmosis membrane device is connected to the inlet of the first high-pressure pump. The osmotic membrane distillation device is equipped with post-treatment mother liquor inlet, reflux liquid inlet, purified process water outlet and concentrated liquid outlet; the second valve is connected with the post-treatment mother liquor inlet, the third valve is connected with the concentrated liquid outlet, the concentrated liquid outlet, the second The two high-pressure pumps are connected to the reflux liquid inlet in sequence.

[0032] During operation, when the post-treatment mother liquor after de...

Embodiment 2

[0036] Add the post-treatment mother liquor containing TMS, water, NaCl and a small amount of polymer powder into the solvent tank to be recovered (the mass fraction of TMS is 4.0%, the NaCl content is 3500ppm, and the conductivity is 0.32×10 3 μS / cm), the post-treatment mother liquor is sent to the basket filter by the feed pump at a flow rate of 400kg / h to remove the remaining polymer powder and impurities in it, and then adsorbed by the activated carbon column filter to remove the remaining trace impurities; then, through The pretreated post-treatment mother liquor enters the reverse osmosis membrane device for desalination through the first high-pressure pump, wherein the reverse osmosis composite membrane module in the reverse osmosis membrane device is a roll-type membrane module, and the reverse osmosis membrane material is a polyarylether sulfone ketone composite membrane , the inlet pressure is 1.00MPa, the outlet pressure is 0.95MPa, and the required membrane area is ...

Embodiment 3

[0039] Add the post-treatment mother liquor containing water, NaF and a small amount of polymer powder to the solvent tank to be recovered (the NaF content is 5400ppm, and the conductivity is 0.34×10 3 μS / cm), the post-treatment mother liquor is pumped to the basket filter by the feed pump at a flow rate of 600kg / h to remove the remaining polymer powder and impurities inside, and then adsorbed by the activated carbon column filter to remove the remaining trace impurities; then, through The pretreated post-treatment mother liquor enters the reverse osmosis membrane device through the first high-pressure pump for the first step of desalination. The reverse osmosis composite membrane module in the reverse osmosis membrane device is a roll-type membrane module, and the reverse osmosis membrane material is polyimide Composite membrane, the inlet pressure is 1.20MPa, the outlet pressure is 1.15MPa, and the required membrane area is 35m 2 , after 8 hours of repeated cycles, the NaF c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com