Low-temperature SCR (Selective Catalytic Reduction) catalyst taking La-doped TiO2 as carrier and preparation method

An SCR catalyst and catalyst technology are applied in the field of SCR catalyst preparation to achieve the effects of good denitration efficiency, good denitration efficiency and easy control of preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

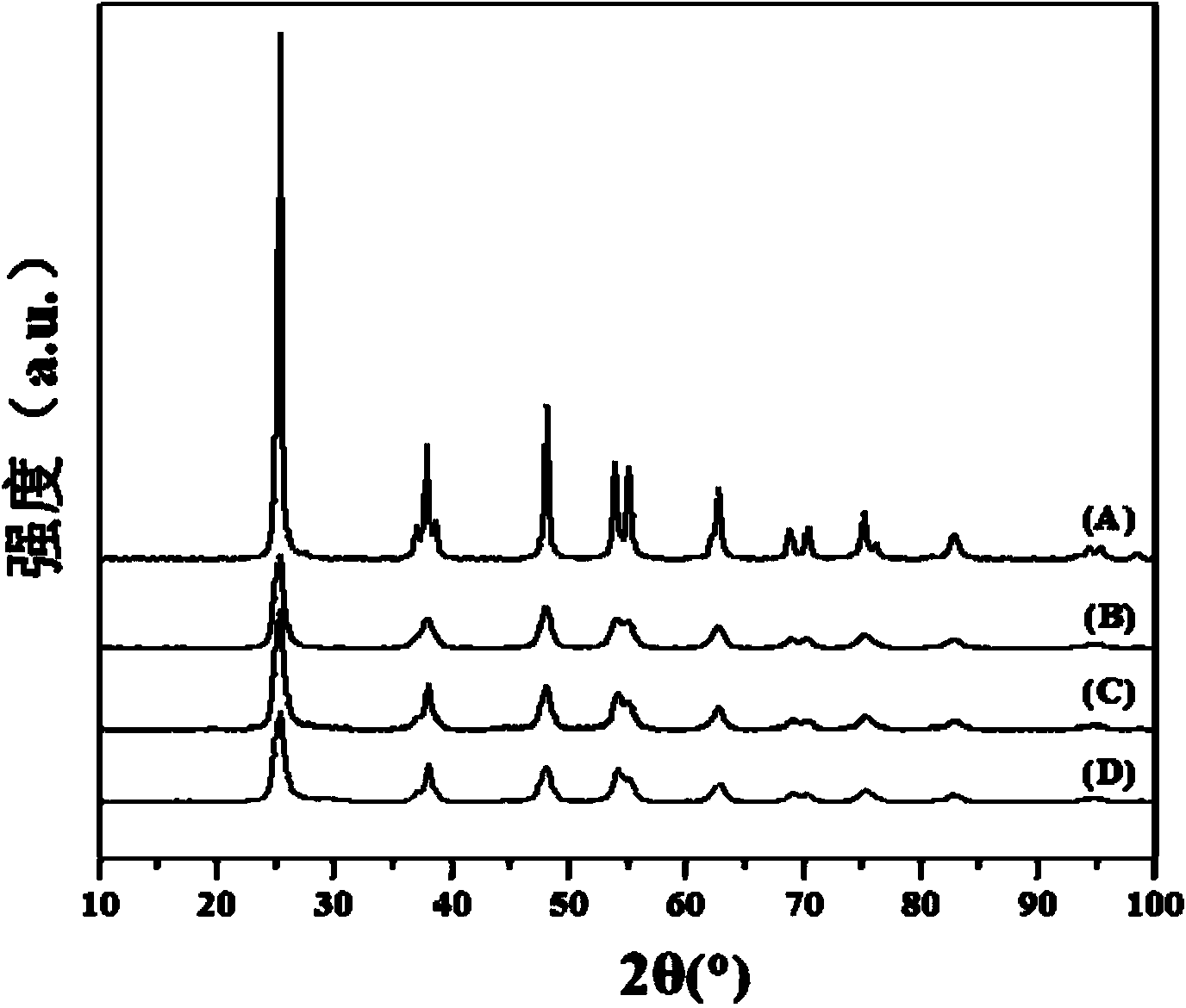

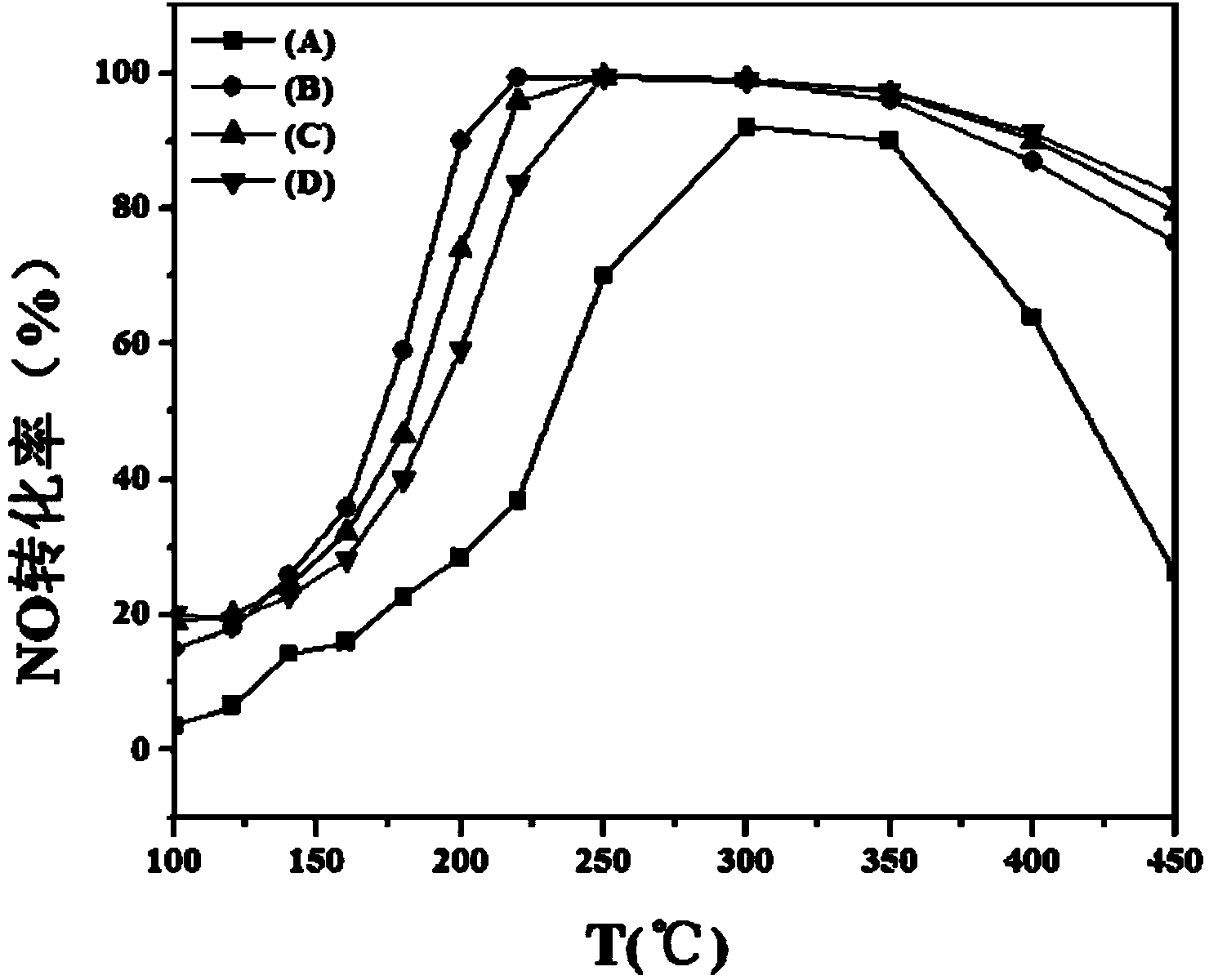

Embodiment 1

[0023] Mix 57.7 mL of tetrabutyl titanate with 66 mL of absolute ethanol and stir for 1 h to obtain solution A, and mix 19.5 mL of acetic acid with 33 mL of absolute ethanol for 1 h to obtain solution B. The solution B was slowly added dropwise to the solution A, the pH of the solution was adjusted to 2 by adding nitric acid, and the sol was obtained after stirring for 2 hours. After aging for 12h, dry at 100°C for 24h, and roast at 500°C for 4h to obtain 1#TiO 2 Carrier: In the oxalic acid solution in which 0.579g of ammonium metavanadate is dissolved, add 1.1g of ammonium molybdate and the above-mentioned 1# carrier, after ultrasonication in a water bath at 60°C for 2h, dry at 80°C for 12h, and roast at 450°C for 3h to obtain 1# catalyst , its Langmuir specific surface is 22m 2 / g.

Embodiment 2

[0025] Mix 55mL tetrabutyl titanate with 63mL absolute ethanol and stir for 1h to obtain A solution, then mix 18.4mL of 0.2mol / L lanthanum nitrate solution, 18.6mL acetic acid and 31.6mL absolute ethanol and stir for 1h A solution of B was obtained. The solution B was slowly added dropwise to the solution A, the pH value of the solution was adjusted to 1 by adding nitric acid, and the sol was obtained after stirring for 2 hours. After aging for 12h, dry at 100°C for 24h, and roast at 500°C for 4h to obtain 2#La 2 o 11 -TiO 2 Carrier: In the oxalic acid solution in which 0.579g of ammonium metavanadate was dissolved, 1.1g of ammonium molybdate and the above-mentioned 2# carrier were added, after ultrasonication in a water bath at 60°C for 2h, drying at 80°C for 12h, and calcination at 450°C for 3h, the catalyst 2# was obtained , its Langmuir specific surface is 110m 2 / g.

Embodiment 3

[0027] Mix 52.7mL tetrabutyl titanate with 60mL absolute ethanol and stir for 1h to obtain A solution, then mix 36.8mL of 0.2mol / L lanthanum nitrate solution, 17.8mL acetic acid and 30mL absolute ethanol and stir for 1h A solution of B was obtained. The solution B was slowly added dropwise to the solution A, the pH value of the solution was adjusted to 1 by adding nitric acid, and the sol was obtained after stirring for 2 hours. After aging for 12h, dry at 100°C for 24h, and roast at 500°C for 4h to obtain 3#La 2 o 11 -TiO 2 Carrier: In the oxalic acid solution in which 0.579g of ammonium metavanadate was dissolved, 1.1g of ammonium molybdate and the above-mentioned 3# carrier were added, after ultrasonication in a water bath at 60°C for 2h, drying at 80°C for 12h, and roasting at 450°C for 3h, the 3# catalyst was obtained , its Langmuir specific surface is 111m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com