Porous resin mold additive manufacturing method for ceramic slip casting

A porous resin and additive manufacturing technology, which is applied in the fields of ceramic forming and additive manufacturing, can solve problems such as expensive, difficult high-pressure grouting, and affect transformation and upgrading, and achieve the requirements of improving quality, optimizing performance, and ensuring customization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The porous resin mold of the flush toilet is prepared by the laser selective sintering rapid prototyping technology of the mixed system formula of resin and pore-forming agent, including the following steps:

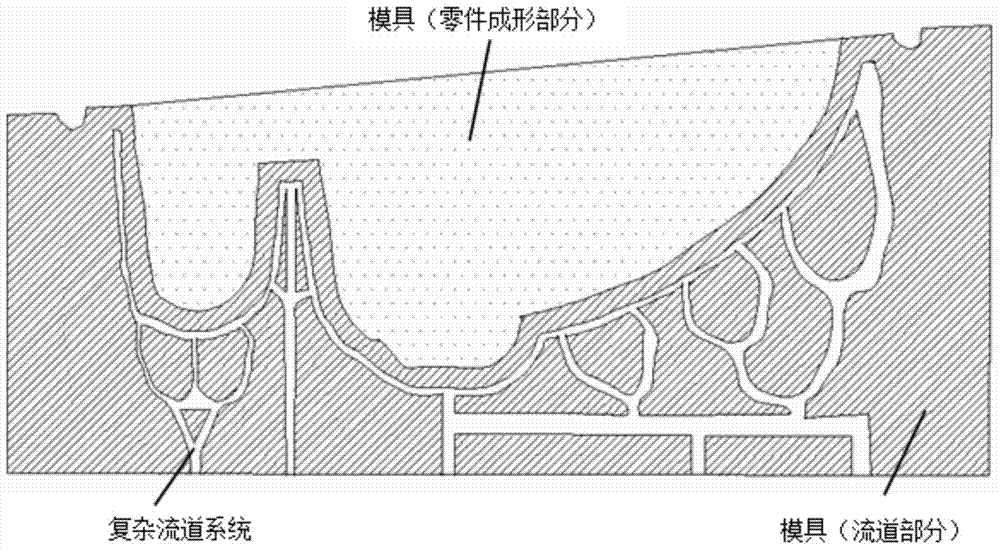

[0046] 1) According to the size, structure and performance requirements of the flush toilet, design its resin mold (including the runner system for drainage in the grouting process), and then use Pro / E software to build a 3D CAD model (refer to figure 1 ) and stored in STL format;

[0047] 2) According to the requirements of the ceramic grouting process specified by this product, the fluidity speed of the ceramic slurry is (170±50s) / 100mL, the water content is 30%-35%, and the density is 1.65-l.9g / cm. Accordingly, the performance index of the porous resin mold is determined as follows: the micropore size is 2.0-3.5 μm, and the porosity is 25-30%;

[0048] 3) According to the determined performance index of the porous resin mold, nylon material is used as the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com